A cement grinding aid that does not change the water requirement of cement standard thickness

A cement grinding aid and water demand technology, applied in the field of cement, can solve the problems of poor compatibility of admixtures, increased water demand for standard viscosity, and high cost, so as to improve compatibility, optimize cement particle gradation, reduce effect of rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

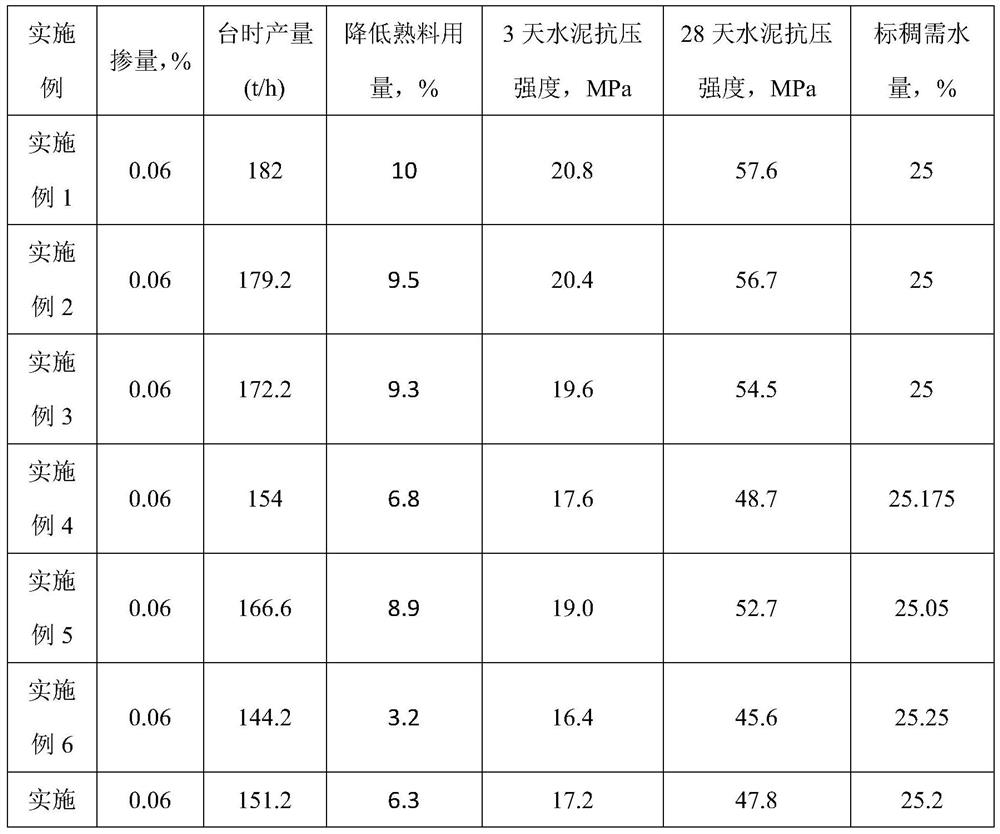

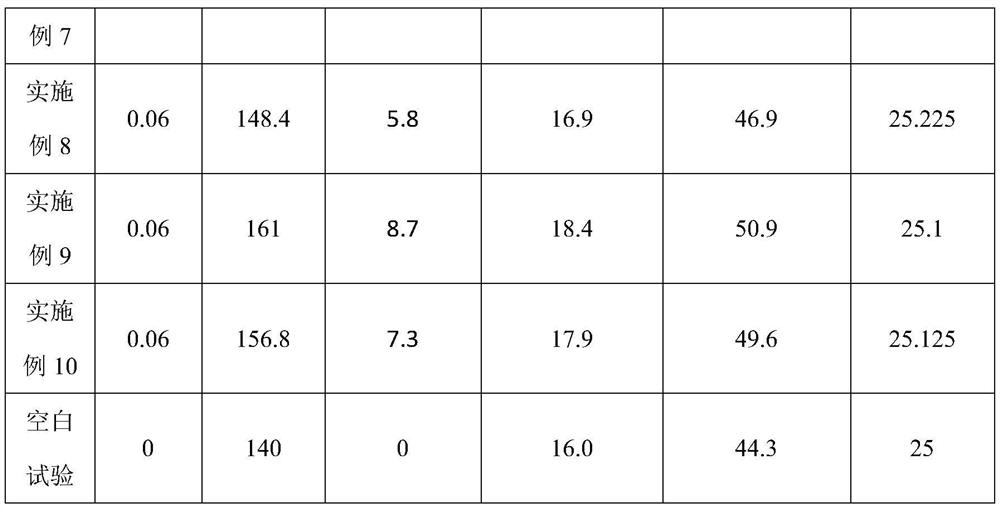

Examples

Embodiment approach

[0025] As an embodiment of the present invention, the thiosulfate is selected from one or more of sodium thiosulfate, potassium thiosulfate, ammonium thiosulfate and lithium thiosulfate.

[0026] In order to maintain the present invention, the addition of the cement grinding aid does not affect the water demand, and the thiosulfate in the present invention is ammonium thiosulfate.

[0027] Polyol

[0028] Polyols are alcohols with two or more hydroxyl groups in their molecules. Polyols are generally soluble in water. Most polyols are viscous liquids or crystalline solids with high boiling points, strong solubility for polar substances, and low toxicity and volatility. Its boiling point, viscosity, relative density and melting point increase with the increase of molecular weight.

[0029] As an embodiment of the present invention, the polyhydric alcohol is selected from alicyclic dihydric alcohol, ethylene glycol, diethylene glycol, dipropylene glycol, 1,4-butanediol, 1,6- ...

Embodiment approach 1

[0057] Embodiment 1. A cement grinding aid that does not change the water demand of cement standard viscosity, the preparation raw materials of the cement grinding aid at least include: thiosulfate, polyols, polyhydroxy monomers, carbonyl pyraldehyde derivatives , carboxyl complex alcohol amines, molasses and water.

[0058] Embodiment 2. A kind of cement grinding aid that does not change the cement standard thick water demand described in embodiment 1, described thiosulfate is selected from sodium thiosulfate, potassium thiosulfate, ammonium thiosulfate, thiosulfate One or more of lithium sulfate.

[0059] Embodiment 3. A kind of cement grinding aid described in embodiment 1 that does not change the cement standard thick water demand, the polyhydric alcohol is selected from the group consisting of cycloaliphatic dibasic alcohols, ethylene glycol, diethylene glycol, a One or more of dipropylene glycol, 1,4-butanediol, 1,6-hexanediol and glycerol.

[0060] Embodiment 4. A kin...

Embodiment 1

[0069] Embodiment 1: This embodiment provides a cement grinding aid that does not change the water requirement of cement standard viscosity. The raw materials for the preparation of the cement grinding aid include: 15 parts of thiosulfate, 20 parts of polyols, 8 parts of body, 12 parts of carbonylpyroaldehyde derivatives, 20 parts of carboxy complex alcohol amines, 15 parts of molasses and 30 parts of water.

[0070] The thiosulfate described in this embodiment is ammonium thiosulfate.

[0071] The polyol described in this embodiment is a mixture of ethylene glycol, glycerol and 1,4-cyclohexanediol in a weight ratio of 2:2:1.

[0072] The polyhydroxy monomer described in this embodiment is stachyose.

[0073] The preparation method of described carbonyl pyroaldehyde derivative is as follows:

[0074] Add water, sodium sulfite, acetone and benzylidene acetone in sequence to the reaction flask with reflux condenser, stir evenly, heat to 50-60°C and keep it warm for 1 hour; add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| brix | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com