Preparation method and application of high-performance IPMC with Nafion-PVA-ES as electrolyte membrane

A technology of nafion-pva-es and electrolyte membrane, which is applied in the direction of heart valves, rayon manufacturing, and human tubular structure devices, can solve the problems of small mechanical properties, short displacement periods, and low porosity, and achieve high water molecular weight. The effect of migration amount, maintenance of stable drive, and outstanding mechanical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 (casting method prepares basement membrane)

[0044] The basement membrane of IPMC is prepared by pouring method: weigh 2.3g of Nafion solution, 0.42g of PVA and 20ml of DMF solvent in a beaker, mix and stir evenly, pump the mixed membrane solution under low pressure to bubble, and then put the bubbled solution on the Stand in the air for one minute to obtain the membrane solution, and finally take out 3ml of the prepared membrane solution and drop it on the glass sheet, then put it on the glue homogenizer, set the speed at 20-50r / min, and the time is 110s, spread the membrane solution, and finally Place in a 70°C oven and dry. Prepare Nafion-PVA base film.

[0045] Using the same method to prepare Nafion basement membrane.

Embodiment 2

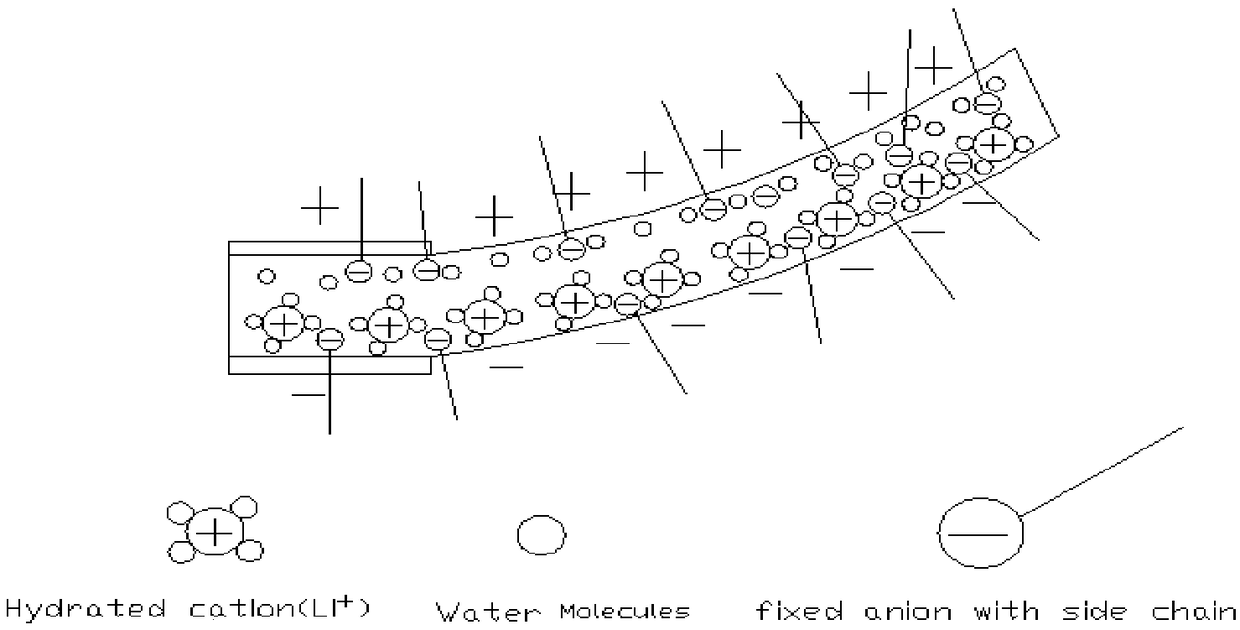

[0046] Example 2 (preparation of electrolyte membrane by non-directional electrospinning)

[0047] Prepare Nafion-PVA-ES electrolyte membrane by non-directional electrospinning: weigh 2.3g Nafion solution, 0.42gPVA and 20ml DMF solvent in a beaker, mix and stir evenly, pump the mixed membrane solution with low pressure to bubble, and then pump the bubble The solution was placed in the air for one minute to obtain a membrane solution, and the membrane solution was placed on an electrospinning device to adjust the spinning conditions and spun onto an aluminum foil receiving plate, and the Nafion-PVA-ES electrolyte membrane was obtained after spinning for 48 hours.

[0048] Using the same method to prepare Nafion-ES electrolyte membrane.

Embodiment 3

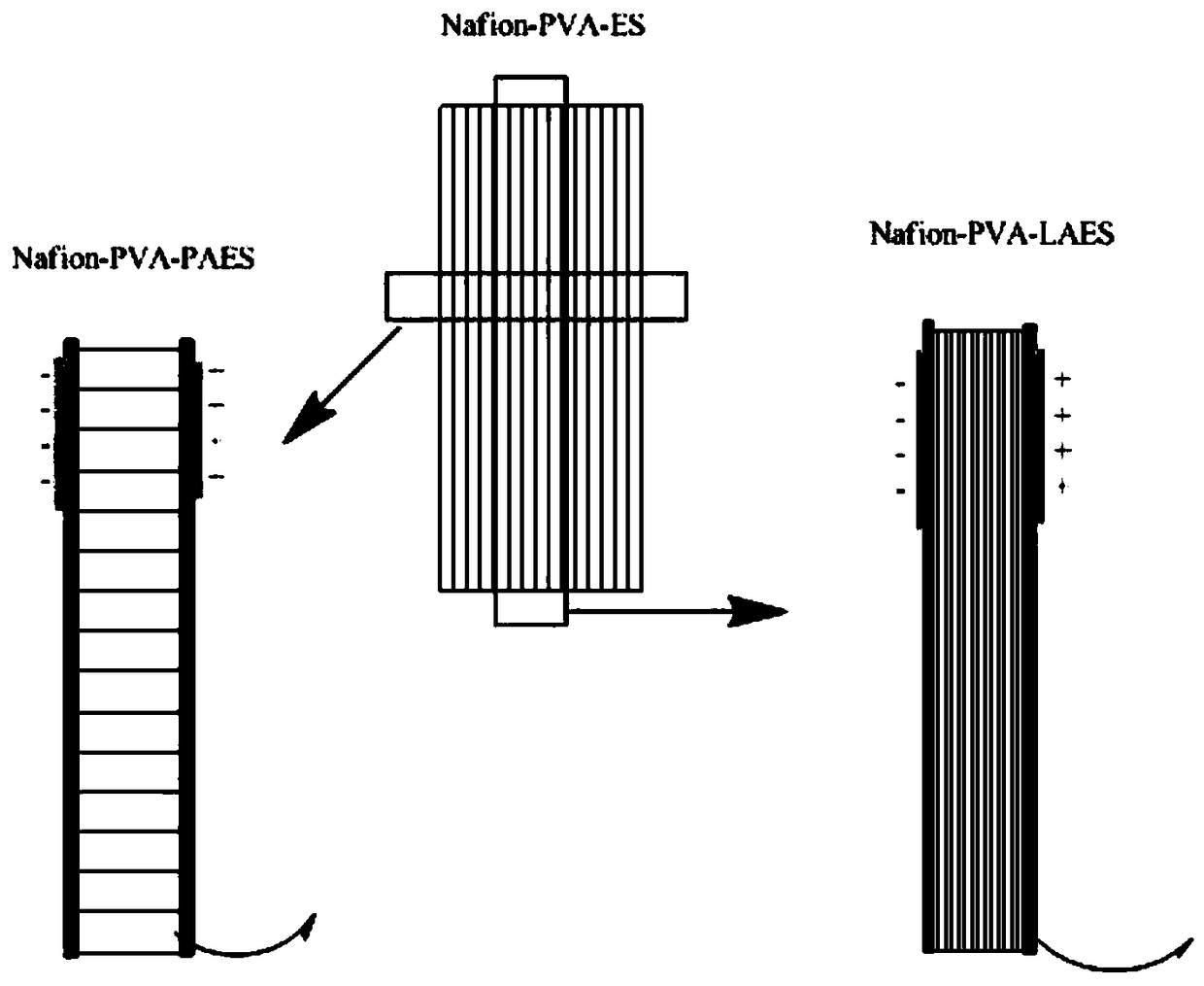

[0049] Embodiment 3 (preparation of electrolyte membrane by directional electrospinning)

[0050] Weigh 2.3g Nafion solution and 0.92g PVA powder into a beaker, then pour 20ml of DMF solvent into it, heat to boil, stir and mix evenly, wait until the PVA is completely fused, pump the membrane solution with low pressure bubbles, and then put the bubbled solution in the air Put the static solution on the electrospinning device to adjust the spinning conditions and spin it to the roller receiving device, and optimize the electrospinning experiment by the orthogonal experimental design method, discuss The method and conditions of Nafion-PVA-PAES film preparation, and the influence of the content of the solution, the distance from the needle to the roller, the flow rate, and the speed of the roller receiver on the average diameter of the fiber were discussed by the orthogonal experiment design method. The flow rate is the most important factor affecting the fiber diameter. The large...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com