Ursodeoxycholic acid soft capsules and preparation method thereof

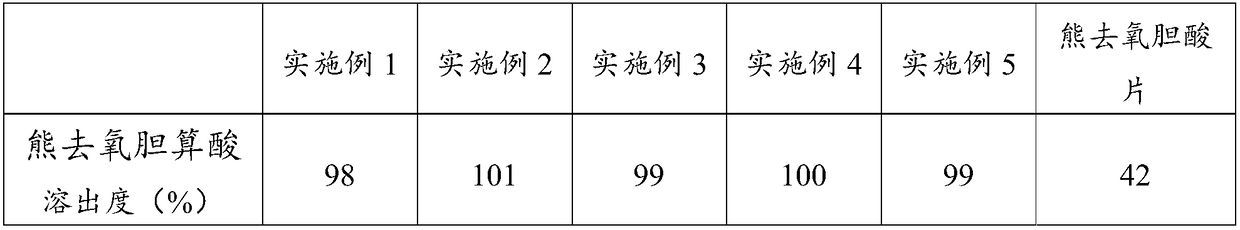

A technology for ursodeoxycholic acid and soft capsules, applied in the field of ursodeoxycholic acid soft capsules and their preparation, can solve the problems of one-sided evaluation standards, unresearched quality stability during shelf life, lack of product stability inspection, etc. Good stability, avoid decomposition and oxidation, high dissolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] As an embodiment of the ursodeoxycholic acid soft capsules of the present invention, the ursodeoxycholic acid soft capsules described in this embodiment include soft capsule contents and soft capsule rubber, wherein the soft capsule contents include the following Components in percentage by weight: ursodeoxycholic acid 26.5%, soybean oil 67%, glyceryl monostearate 5% and poloxamer 1.5%; the soft capsule rubber includes the following components in percentage by weight: gelatin 60% , Glycerin 30%, Tartrazine 0.5%, Calcium Carbonate 1.0%, Methylparaben 0.5% and Water 8%.

[0041] The preparation method of the ursodeoxycholic acid soft capsule described in the present embodiment comprises the following steps:

[0042] (1) Chemical glue: Use a shear emulsification mixer to prepare an aqueous suspension of calcium carbonate; dissolve tartrazine in water to make a pigment solution; put water and glycerin into the chemical glue tank, stir, and heat to 60°C, add Methylparaben, ...

Embodiment 2

[0049] As an embodiment of the ursodeoxycholic acid soft capsules of the present invention, the ursodeoxycholic acid soft capsules described in this embodiment include soft capsule contents and soft capsule rubber, wherein the soft capsule contents include the following Components in percentage by weight: ursodeoxycholic acid 24%, peanut oil 70%, glyceryl distearate 4% and phospholipids 2%; the soft capsule rubber skin includes the following components in percentage by weight: gelatin 63.5%, sorbitol 25%, Talc 1.0%, Ethylparaben 0.5%, and Water 10%.

[0050] The preparation method of the ursodeoxycholic acid soft capsule described in the present embodiment comprises the following steps:

[0051] (1) Chemical glue: Use a shear emulsification mixer to prepare an aqueous suspension of talc powder; put water and sorbitol into the chemical glue tank, stir, and heat to 70°C, add ethyl paraben, stir until dissolved, add Gelatin, continue to stir and heat, vacuumize to make the vacuu...

Embodiment 3

[0058] As an embodiment of the ursodeoxycholic acid soft capsules of the present invention, the ursodeoxycholic acid soft capsules described in this embodiment include soft capsule contents and soft capsule rubber, wherein the soft capsule contents include the following Components in percentage by weight: ursodeoxycholic acid 25%, corn oil 46.8%, peanut oil 25%, glyceryl monostearate 3% and Tween 0.2%; the soft capsule rubber includes the following components in percentage by weight: Gelatin 67.8%, Propylene Glycol 25%, Iron Oxide Red 0.2%, Titanium Dioxide 0.5%, Propylparaben 0.5%, and Water 6%.

[0059] The preparation method of the ursodeoxycholic acid soft capsule described in the present embodiment comprises the following steps:

[0060] (1) Chemical glue: use a shear emulsification mixer to prepare the aqueous suspensions of titanium dioxide and iron oxide red respectively, and set aside; put water and glyceryl monostearate into the glue tank, stir, and heat to 75°C, add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com