A preparation method and recovery method of an environment-friendly low-mercury catalyst

A low-mercury catalyst and mercuric chloride technology, applied in chemical recovery, chemical instruments and methods, mercury oxide, etc., can solve the problems of low mechanical properties of activated carbon, chemical corrosion resistance, weak salt spray resistance, short service life, etc. , to achieve excellent corrosion resistance, strong chemical corrosion resistance, and thorough recovery methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

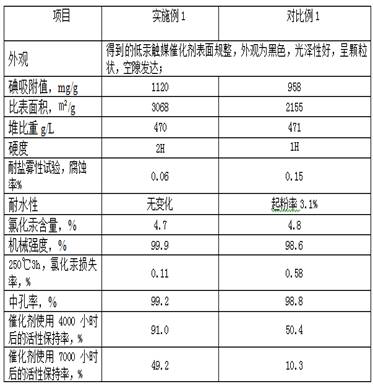

Examples

Embodiment 1

[0025] Embodiment 1 A kind of preparation method of environment-friendly low-mercury catalyst

[0026] A kind of preparation method of environment-friendly low-mercury catalyst of the present invention mainly comprises the following steps:

[0027] (1) Selection of carrier materials

[0028] High-quality macadamia husks are selected as raw materials. The macadamia husks are fresh macadamia husks of that year, with the outer layer of burrs removed. The maximum diameter is 8-9cm, the short diameter is 5-6cm, and the moisture content is 12%.

[0029] (2) Alkali soaking

[0030] Add the above fresh macadamia nut shells to 35% potassium hydroxide solution and soak for 12 hours, then dry them in a converter, turn on the vacuum system, and dry them at a vacuum degree of 0.08MPa and a temperature of 125°C.

[0031] (3) activation

[0032] Carry out carbonization according to the conventional method to obtain carbonized material, and treat the carbonized material with molten anhydro...

Embodiment 2

[0050] Embodiment 2 A recovery method of environment-friendly low-mercury catalyst

[0051] The raw material source of a kind of environment-friendly low-mercury catalyst catalyst of the present invention: adopt the low-mercury catalyst catalyst prepared by above-mentioned embodiment 1, through the low-mercury catalyst catalyst obtained after 9000 hours of synthetic vinyl chloride, its mercuric chloride content is 3.2- 4.5%, the recovery method of described low-mercury catalytic catalyst, comprises the following steps:

[0052] (1) Acidification

[0053] Weigh 800g of the raw material low-mercury catalyst and put it into the extraction kettle. The content of mercury chloride is 3.5%.

[0054] (2) Subcritical carbon dioxide extraction

[0055] Inject subcritical carbon dioxide into the extraction kettle, keep the volume ratio of subcritical carbon dioxide and acidified low-mercury catalyst at 9:1, extract for 4.5 hours at an extraction temperature of 50°C, an extraction press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| iodine adsorption value | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com