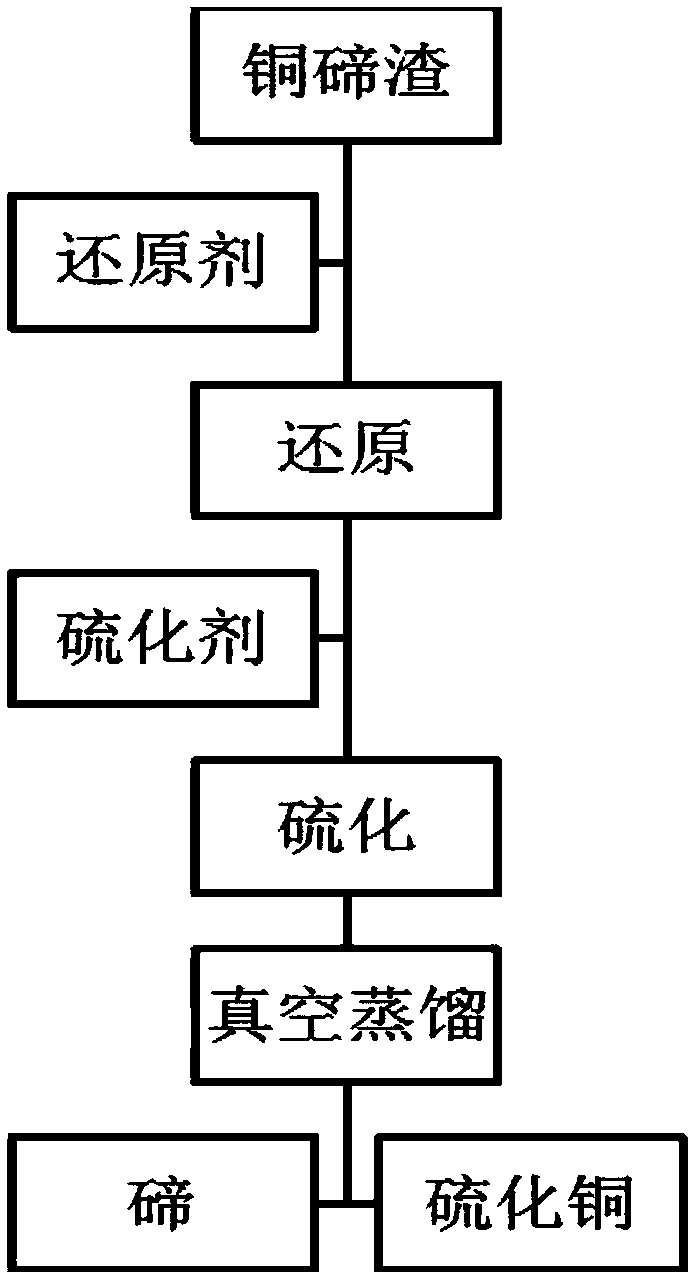

Method for extracting tellurium from copper-tellurium slag

A technology of tellurium slag and copper sulfide, which is applied in the field of tellurium extraction, can solve the problems of lengthy process, low tellurium recovery rate, and large environmental pollution, and achieve the effects of shortening the process flow, benefiting environmental protection, and producing no three wastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036]Step 1. Heat 500kg copper tellurium slag (containing Te ~ 28%) in a container to 600°C to make it melt, then gradually add 50kg of carbon powder during the stirring process, the reaction will not proceed after 2 hours, stop heating and stirring, and let it stand. Set to cool to obtain copper tellurium slag reduction product.

[0037] Step 2. After crushing the reduction product obtained in step 1, mix it with 45kg of sulfur and place it in a container for heating while stirring. The temperature is controlled at about 440°C, and the reaction time is 1h to replace tellurium from the copper-tellurium slag. , to obtain a mixture of tellurium and copper sulfide.

[0038] Step 3: Put the mixture of tellurium and copper sulfide in a vacuum furnace with a pressure of 70 Pa and a distillation temperature of 1450°C. Distill under these conditions for 4 hours to obtain 137.50 kg of volatile matter and 294.55 kg of residue.

[0039] After analysis, the volatile matter contains 99.4...

Embodiment 2

[0041] Step 1. Heat 500kg of copper tellurium slag (tested to contain Te ~ 28%) in a container to 550°C to melt it, stir and gradually add 40kg of carbon powder. After 2.5 hours of reaction, no reaction occurs, stop heating and stirring, and let it stand. Set aside to cool.

[0042] Step 2: After crushing the copper-tellurium slag obtained from the reduction, mix it with 40kg of sulfur and heat it in a container. The temperature is controlled at about 400°C for sulfidation. The reaction time is 1.5h, and the tellurium is replaced from the copper-tellurium slag to obtain tellurium and copper sulfide mixture.

[0043] Step 3: Put the mixture of tellurium and copper sulfide in a vacuum furnace, control the pressure in the furnace to 50 Pa, and distill at a distillation temperature of 1250°C for 5 hours. Obtained 136.60kg of volatile matter and 289.80kg of residue.

[0044] After analysis, the volatile matter contained 99.53% tellurium, and the residue contained 1.21% tellurium....

Embodiment 3

[0046] Step 1. After mixing 500kg of copper tellurium slag (Te ~ 28% detected) and 30Kg of carbon powder evenly, slowly heat to 500°C in a container to melt and reduce it. The reaction time is 3h and no longer reacts. Stop heating and cooling.

[0047] Step 2: The copper telluride obtained by reduction is crushed and mixed with 35kg of sulfur, and then heated in a closed container at a controlled temperature of about 360°C. The reaction time is 2 hours, and the tellurium is replaced from the copper tellurium slag to obtain tellurium and copper sulfide. mixture.

[0048] Step 3: Put the mixture of tellurium and copper sulfide in a vacuum furnace, control the pressure in the furnace to 30 Pa, and distill at a distillation temperature of 1050°C for 6 hours. After vacuum distillation, 136.10kg of volatile matter and 277.45kg of residue were obtained.

[0049] After analysis, the volatile matter contains 99.59% tellurium, and the residue contains 1.39% tellurium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com