Nanometer praseodymium-zirconium yellow material and preparation method thereof

A yellow and nano technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as harm to human health, difficulty in mass production, environmental pollution, etc., to achieve bright color, mild and easy-to-control reaction conditions, Low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

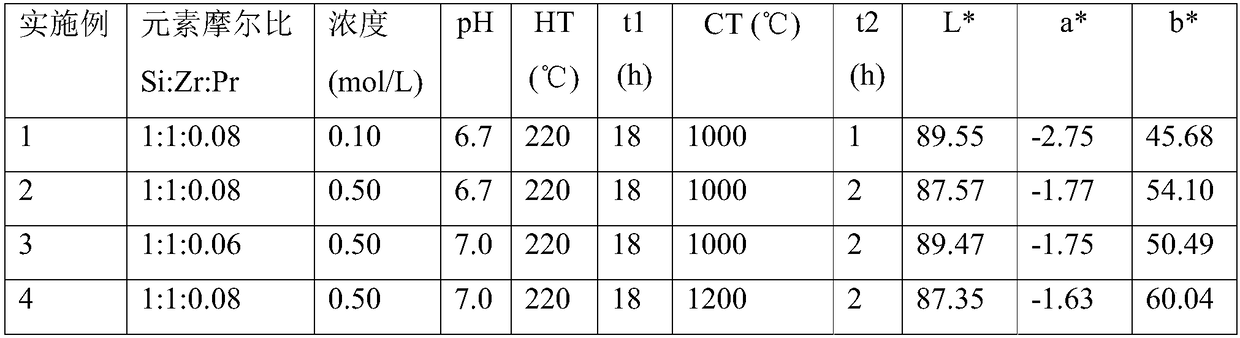

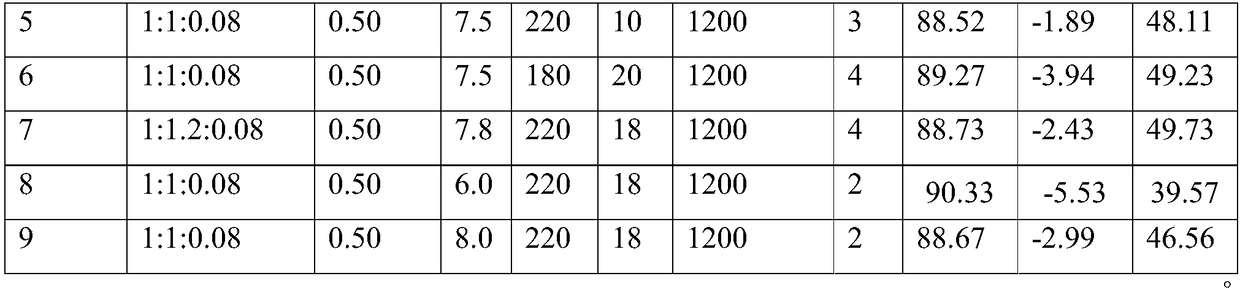

Examples

preparation example Construction

[0027] Preparation of praseodymium nitrate. Dissolve praseodymium oxide in nitric acid to prepare praseodymium nitrate solution.

[0028] Select certain soluble silicon sources and soluble zirconium sources to prepare aqueous solutions with certain concentrations respectively. The concentration of the silicon ion and zirconium ion aqueous solution may be 0.1mol / L-0.5mol / L. The soluble silicon source can be selected from sodium metasilicate or / and potassium silicate. The soluble zirconium source may be selected from zirconium nitrate, zirconyl nitrate, zirconium oxychloride or / and zirconium chloride and the like.

[0029] The praseodymium nitrate solution, the soluble silicon source aqueous solution and the soluble zirconium source aqueous solution are uniformly mixed to obtain a mixed solution. The preparation sequence of the mixed solution is preferably: add the praseodymium nitrate solution into the soluble silicon source aqueous solution (silicon ion solution), and then ...

Embodiment 1

[0036] (1) Weigh 1.61g zirconium oxychloride octahydrate, dissolve it in 50ml water, and stir to obtain a 0.1mol / L zirconium oxychloride aqueous solution; weigh 1.42g sodium metasilicate nonahydrate, dissolve it in 50ml water, and stir to prepare Obtain a 0.1mol / L sodium silicate solution; weigh 0.068g of praseodymium oxide, add concentrated nitric acid dropwise, and gently stir to obtain a clear praseodymium nitrate solution. Add the praseodymium nitrate solution into the sodium silicate aqueous solution, and then add the zirconium oxychloride aqueous solution into the above-mentioned two-water mixed solution under sufficient stirring to obtain a mixed solution. Slowly add sodium hydroxide solution dropwise to the mixed solution, adjust the pH to 6.7, and keep the pH constant for at least 15 minutes to obtain the precursor solution;

[0037] (2) Put the precursor solution in a hydrothermal kettle, and conduct a hydrothermal reaction at 220°C for 18 hours; then filter and wash...

Embodiment 2

[0039](1) Take by weighing 8.05g zirconium oxychloride octahydrate, be dissolved in 50ml water, stir to make 0.5mol / L zirconium oxychloride aqueous solution; Take by weighing 7.10g sodium metasilicate nonahydrate, be dissolved in 50ml water, stir to make Obtain a 0.5 mol / L sodium silicate solution; weigh 0.341 g of praseodymium oxide, add concentrated nitric acid dropwise, and gently stir to obtain a clear praseodymium nitrate solution. Add the praseodymium nitrate solution into the sodium silicate aqueous solution, and then add the zirconium oxychloride aqueous solution into the above-mentioned two-water mixed solution under sufficient stirring to obtain a mixed solution. Slowly add sodium hydroxide solution dropwise to the mixed solution, adjust the pH to 6.7, and keep the pH constant for at least 15 minutes to obtain the precursor solution;

[0040] (2) Put the precursor solution in a hydrothermal kettle, and conduct a hydrothermal reaction at 220°C for 18 hours; then filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com