Preparation method of glass fiber sizing agent

A glass fiber and sizing technology, applied in the field of preparation of glass fiber sizing, can solve the problems of poor quality, non-disclosure, and low quality of sizing, and achieve uniform distribution, good film-forming properties, and good clustering properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

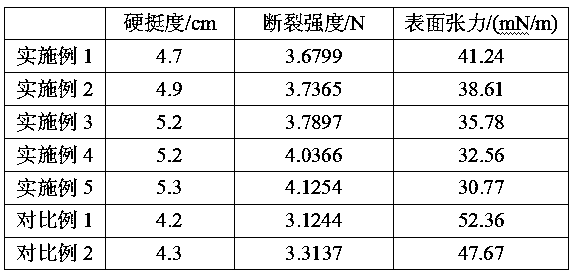

Examples

Embodiment 1

[0021] (1) Weigh 80g of wheat bran into a 500mL round-bottomed three-neck flask, then add 300mL of deionized water, reflux and stir at 85°C for 2 hours, filter, remove the residue, and dilute the filtrate to 400mL to obtain wheat bran bran extract;

[0022] (2) Heat 400mL of wheat bran extract to 40°C, add 3g of ammonium persulfate to react for 15min, then adjust the pH value of the solution to 7.0 with 1mol / L NaOH, add 15g of acrylic acid, and at the same time add 2g of sodium bisulfite, at 45°C After 3 hours of grafting reaction, adjust the pH value to 6.0 with phosphate buffer, then add 2 g of isoamylase, react for 24 hours, heat at 85°C for 10 minutes, and pass through a 80-mesh sieve to obtain an emulsion;

[0023] (3) Mix isopropyl myristate, mixed surfactant and 0.15mol / L sodium chloride aqueous solution at a volume ratio of 61:25:14, and emulsify with a high-speed emulsifying homogenizer at 13500 r / min for 2 minutes. Then the emulsion is homogenized twice at 30 MPa wi...

Embodiment 2

[0027] (1) Weigh 80g of wheat bran into a 500mL round-bottomed three-neck flask, then add 300mL of deionized water, reflux and stir at 85°C for 2 hours, filter, remove the residue, and dilute the filtrate to 400mL to obtain wheat bran bran extract;

[0028] (2) Heat 400mL of wheat bran extract to 40°C, add 3g of ammonium persulfate to react for 15min, then adjust the pH value of the solution to 7.0 with 1mol / L NaOH, add 15g of acrylic acid, and at the same time add 2g of sodium bisulfite, at 45°C After 3 hours of grafting reaction, adjust the pH value to 6.0 with phosphate buffer, then add 2 g of isoamylase, react for 24 hours, heat at 85°C for 10 minutes, and pass through a 80-mesh sieve to obtain an emulsion;

[0029] (3) Mix isopropyl myristate, mixed surfactant and 0.15mol / L sodium chloride aqueous solution at a volume ratio of 61:25:14, and emulsify with a high-speed emulsifying homogenizer at 13500 r / min for 2 minutes. Then the emulsion is homogenized twice at 30 MPa wi...

Embodiment 3

[0033] (1) Weigh 80g of wheat bran into a 500mL round-bottomed three-neck flask, then add 300mL of deionized water, reflux and stir at 85°C for 2 hours, filter, remove the residue, and dilute the filtrate to 400mL to obtain wheat bran bran extract;

[0034] (2) Heat 400mL of wheat bran extract to 40°C, add 3g of ammonium persulfate to react for 15min, then adjust the pH value of the solution to 7.0 with 1mol / L NaOH, add 15g of acrylic acid, and at the same time add 2g of sodium bisulfite, at 45°C After 3 hours of grafting reaction, adjust the pH value to 6.0 with phosphate buffer, then add 2 g of isoamylase, react for 24 hours, heat at 85°C for 10 minutes, and pass through a 80-mesh sieve to obtain an emulsion;

[0035] (3) Mix isopropyl myristate, mixed surfactant and 0.15mol / L sodium chloride aqueous solution at a volume ratio of 61:25:14, and emulsify with a high-speed emulsifying homogenizer at 13500 r / min for 2 minutes. Then the emulsion is homogenized twice at 30 MPa wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap