Antibacterial putty powder with long service life and preparation method thereof

A putty powder, long-life technology, used in filling slurry and other directions, can solve the problems of low inner layer hardness, low calcification rate, poor waterproof performance, etc., to achieve good uniformity, high bond strength, easy construction and grinding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

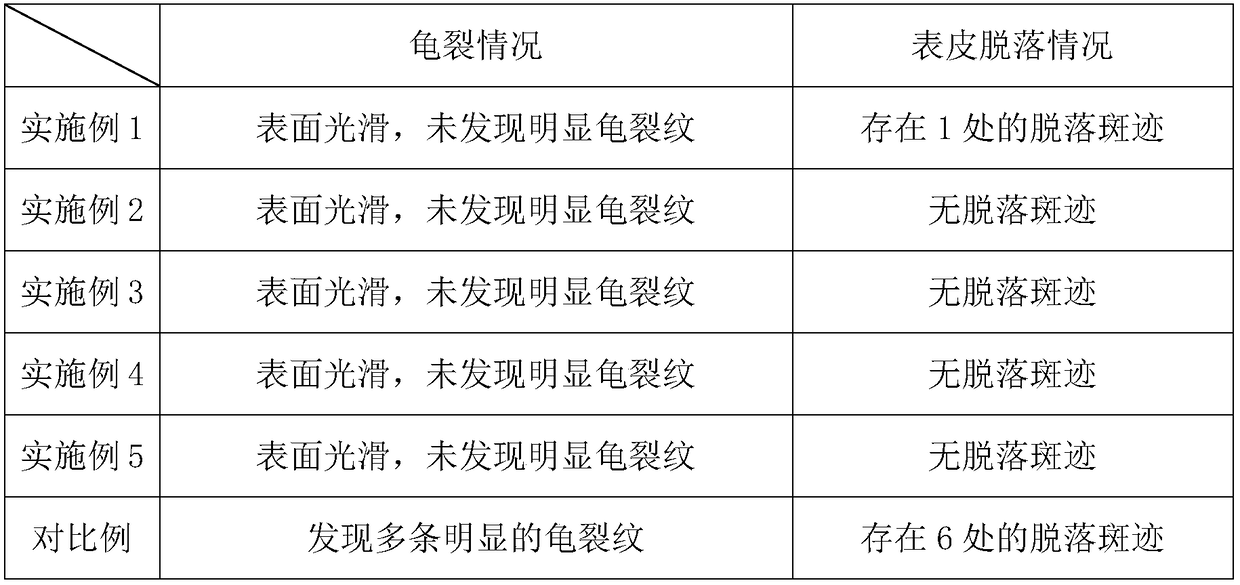

Embodiment 1

[0023] A putty powder with long antibacterial life, comprising the following raw materials in parts by weight: 160 parts of white cement, 25 parts of redispersible latex powder, 4 parts of carboxymethyl cellulose, 4 parts of modified starch ether, 50 parts of talcum powder , 60 parts of gray calcium powder, 6 parts of negative ion powder, 8 parts of far-infrared ceramic powder, 10 parts of bamboo charcoal powder, 3 parts of titanate coupling agent, 12 parts of silvery white vermiculite powder, 10 parts of paraffin wax, 300 parts of heavy calcium powder, 50 parts of kaolin, 40 parts of glass fiber.

[0024] In the present embodiment, the heavy calcium powder is a heavy calcium powder with a particle size of 6 microns and a whiteness of 70%; the kaolin is calcined kaolin with a particle size of 3 microns and a silicon dioxide content greater than 65%; The glass fibers are alkali-free chopped glass fibers with a size specification of 1.5 cm; the titanate coupling agent is titanat...

Embodiment 2

[0030] A putty powder with long antibacterial life, comprising the following raw materials in parts by weight: 250 parts of white cement, 60 parts of redispersible latex powder, 8 parts of carboxymethyl cellulose, 9 parts of modified starch ether, and 80 parts of talcum powder , 90 parts of gray calcium powder, 12 parts of negative ion powder, 15 parts of far-infrared ceramic powder, 20 parts of bamboo charcoal powder, 6 parts of titanate coupling agent, 25 parts of silvery white vermiculite powder, 15 parts of paraffin wax, 500 parts of heavy calcium powder, 100 parts of kaolin, 85 parts of glass fiber.

[0031] In the present embodiment, the heavy calcium powder is a heavy calcium powder with a particle size of 8 microns and a whiteness of 75%; the kaolin is calcined kaolin with a particle size of 4 microns and a silicon dioxide content greater than 65%; The glass fibers are alkali-free chopped glass fibers with a size specification of 2 cm; the titanate coupling agent is ti...

Embodiment 3

[0037]A putty powder with long antibacterial life, comprising the following raw materials in parts by weight: 200 parts of white cement, 45 parts of redispersible latex powder, 6 parts of carboxymethyl cellulose, 6.5 parts of modified starch ether, 65 parts of talcum powder , 75 parts of gray calcium powder, 9 parts of negative ion powder, 11 parts of far-infrared ceramic powder, 15 parts of bamboo charcoal powder, 4.5 parts of titanate coupling agent, 17 parts of silvery white vermiculite powder, 13 parts of paraffin wax, 400 parts of heavy calcium powder, 72 parts of kaolin, 62 parts of glass fiber.

[0038] In the present embodiment, the heavy calcium powder is a heavy calcium powder with a particle size of 7 microns and a whiteness of 73%; the kaolin is calcined kaolin with a particle size of 3.5 microns and a silicon dioxide content greater than 65%; The glass fibers are alkali-free chopped glass fibers with a size of 1.7 cm; the titanate coupling agent is titanate coupli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com