Fireproof paint for steel structure

A fireproof coating and steel structure technology, applied in the field of coatings, can solve the problems of high temperature resistance, water resistance and poor aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

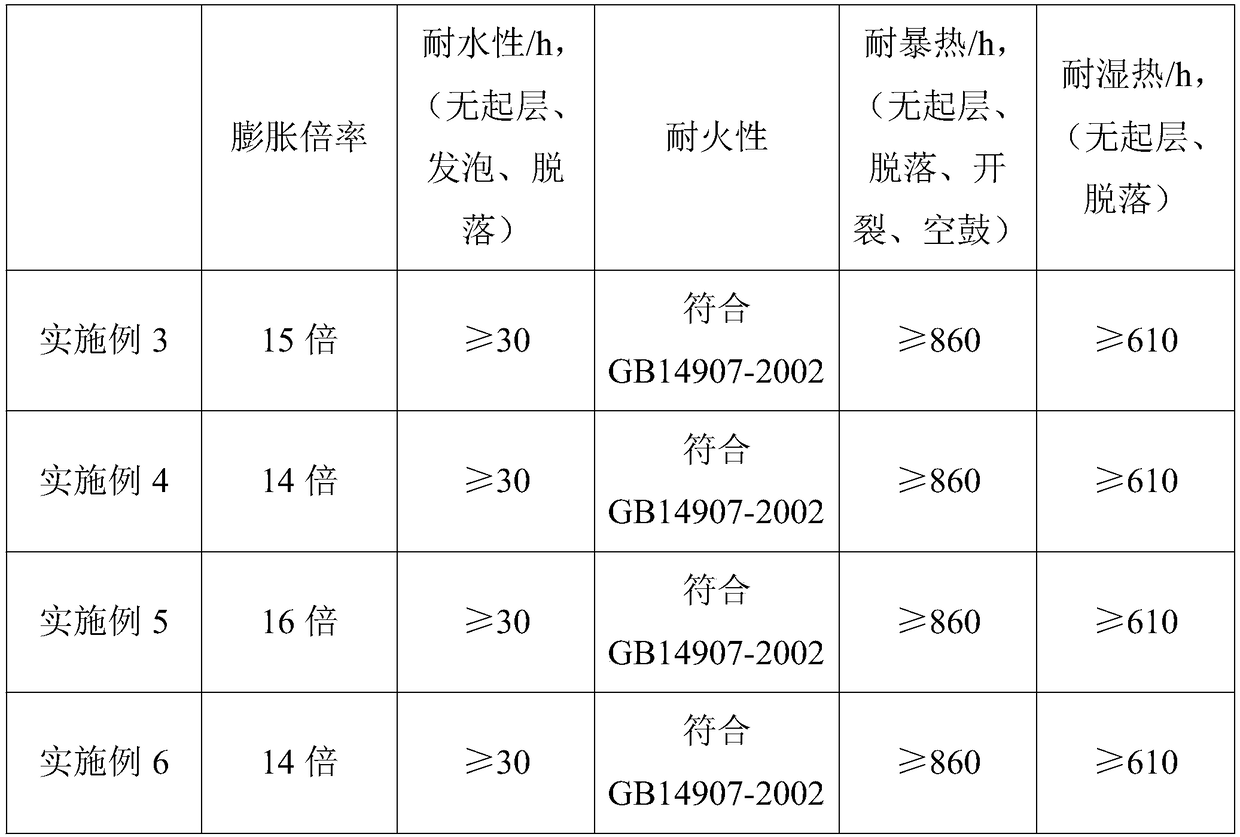

Examples

Embodiment 1

[0019] The preparation method of flame retardant is:

[0020] Add nano-silica to the polypolyol phosphate liquid for ultrasonic dispersion to obtain a suspension. After the suspension is heated to 85°C, vinyltrimethoxysilane is added dropwise to react. After the end, it can be dried by centrifugal vacuum. The mass ratio of nano-silica, polypolyol phosphate and vinyltrimethoxysilane is 5:14:1.

Embodiment 2

[0022] The preparation method of flame retardant is:

[0023] Add nano-silica to the polypolyol phosphate liquid for ultrasonic dispersion to obtain a suspension. After the suspension is heated to 80°C, γ-methacryloxypropyltrimethoxysilane is added dropwise to react. After the end Centrifuge and vacuum dry. The mass ratio of nano silicon dioxide, polypolyol phosphate and γ-methacryloxypropyltrimethoxysilane is 8:17:3.

Embodiment 3

[0025] A kind of fireproof paint for steel structure, according to parts by weight, comprises the following components:

[0026] 50 parts of acrylic emulsion, 28 parts of styrene-acrylic emulsion, 6 parts of ammonium bicarbonate, 7 parts of pentaerythritol, 12 parts of flame retardant of embodiment 1, 0.6 part of sodium hexametaphosphate wetting agent, 0.5 part of water-based acrylate copolymer and titanium 10 parts of white powder, 10 parts of montmorillonite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com