Isocyanate based wood material adhesive and application method thereof

An isocyanate-based, wood-based material technology, applied in polyurea/polyurethane adhesives, adhesive types, non-polymer adhesive additives, etc., can solve difficult problems such as waterproofing of wood-based panels, and achieve excellent waterproof performance The effect of improving mechanical properties, mechanical strength, and enhancing water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] Preparation of polyisocyanate derivatives

[0060] Heat the polyisocyanate to 60-70°C, add the polyol into the polyisocyanate under stirring condition, keep the temperature at 60-70°C and react for 2-3 hours to obtain polyisocyanate derivatives. The reaction conditions and results are shown in Table 1.

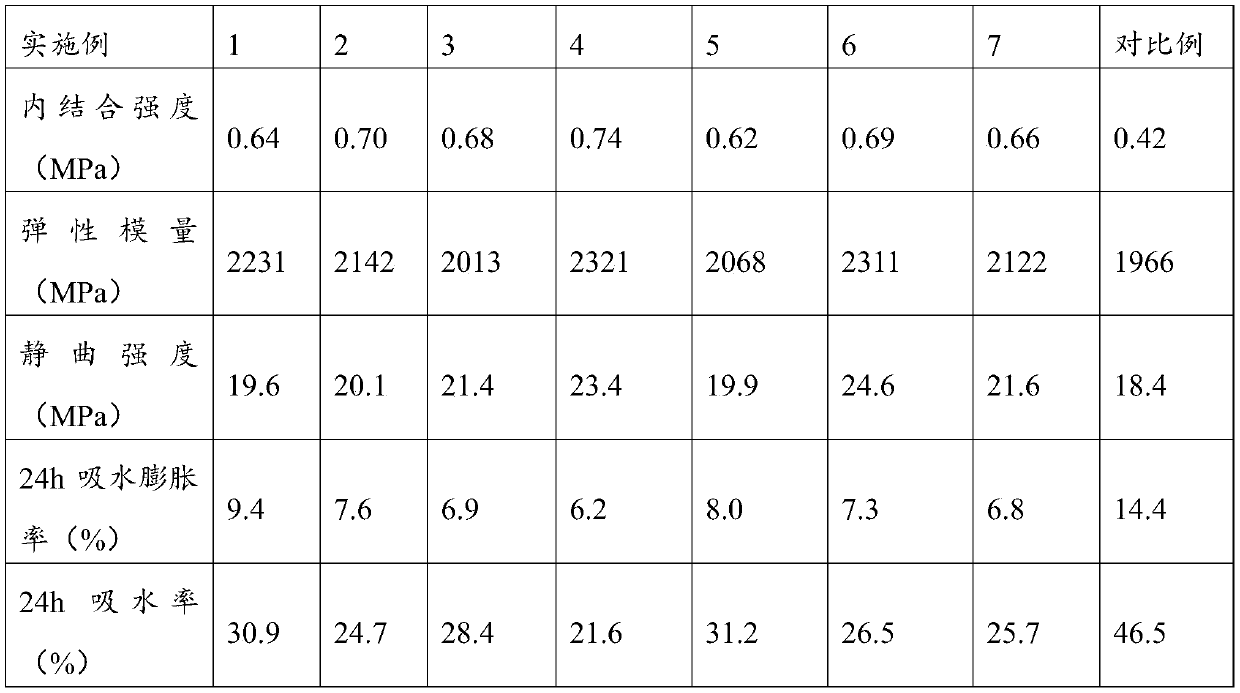

[0061] Table 1 Derivative reaction conditions and results

[0062]

Embodiment 1

[0064] Poplar shavings with a moisture content of 8-10wt% were selected as the wood substrate for the press plate test. Weigh 2000g of poplar wood shavings on the surface and add them to the mixer, respectively weigh 60g of polymethylene polyphenyl polyisocyanate PM-200 (Wanhua Chemical Group Co., Ltd.), polyamide 651 (Changzhou Deye Chemical Co., Ltd., amine value 380~450mg / KOH / g) 24g, silane coupling agent γ-aminopropyltriethoxysilane (KH-550, Guangzhou Zhongjie Chemical Technology Co., Ltd.) 0.3g in a beaker, connect a spray gun to air compression Machine, the above three raw materials are sprayed into the mixer in the stirring state from the spray gun in turn and stirred for 40-60s. Carry out the sizing of core shavings according to the same process conditions. According to the paving ratio of 360g surface layer poplar wood shavings + 980g core layer shavings + 360g surface layer poplar wood shavings, the shavings are paved in a 350mm*350mm*100mm mold and pre-pressed into...

Embodiment 2

[0066] Poplar shavings with a moisture content of 8-10wt% were selected as the wood substrate for the press plate test. Take by weighing 2000g of surface layer poplar wood shavings and add in the mixer, respectively weigh 50g polymethylene polyphenyl polyisocyanate derivative 1#, 10g polymethylene polyphenyl polyisocyanate derivative 6#, polyamide 651 (Changzhou Germany Ye Chemical Co., Ltd.) 3g, polyamide 200 (Changzhou Deye Chemical Co., Ltd., amine value 230 ~ 260mg KOH / g) 3g, isopropyl titanate triisostearate (PN-130, Nanjing Pinning coupling agent Co., Ltd.) 15g in a beaker, connect a spray gun to an air compressor, spray the above three raw materials from the spray gun into the mixer under stirring state and stir for 40-60s. Carry out core layer shaving sizing according to the same process. According to the paving ratio of 360g surface shavings + 980g core shavings + 360g surface shavings, the shavings are laid in a 350mm*350mm*100mm mold and pre-pressed into a slab, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| amine value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com