A kind of electromagnetic wave absorber and preparation method thereof

An absorbent and electromagnetic wave technology, applied in chemical instruments and methods, electrical components, and other chemical processes, can solve the problem of single absorption frequency band, achieve simple preparation process, improve impedance matching, and increase absorption bandwidth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Preparation methods include:

[0035] Step S101 , respectively providing a first powder made of sendust and a second powder made of manganese zinc ferrite.

[0036] The above-mentioned first powder and second powder can be obtained by appropriate processing of commercially available sendust and manganese zinc ferrite.

[0037] Among them, sendust can be prepared by metallurgical process. Simple and easy, in the embodiment of the present invention, the first powder is made of sendust powder through ball milling.

[0038] For example, elemental iron, elemental silicon, and elemental aluminum are used to prepare sendust aluminum alloy powder through a gas atomization method. The amount of the elemental metal of sendust is compounded according to the element ratio of the first powder. For example, 100g of sendust powder is made by ball milling 85g of iron, 9.6g of silicon and 5.4g of aluminum. Before using sendust, the oxide layer can usually be removed, such as acid et...

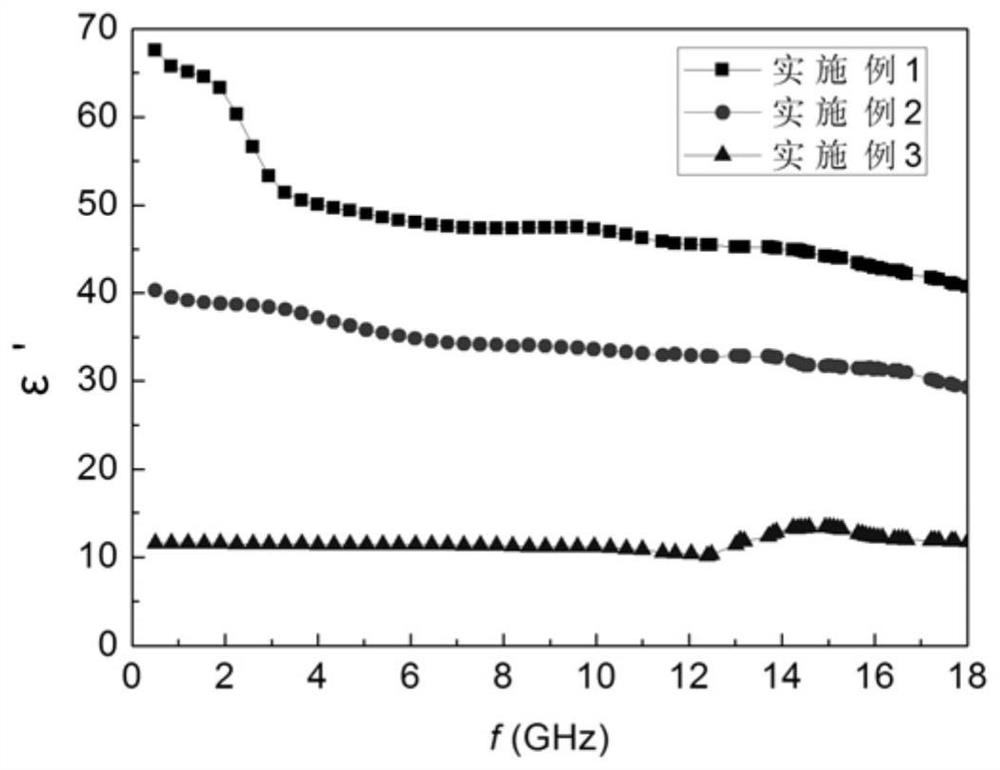

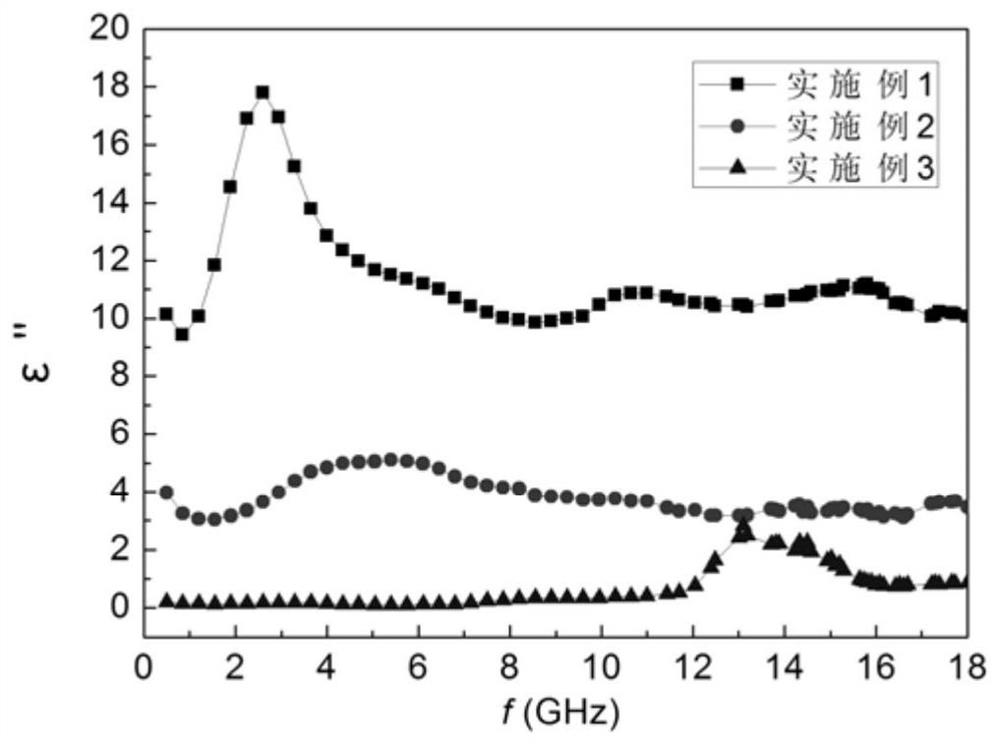

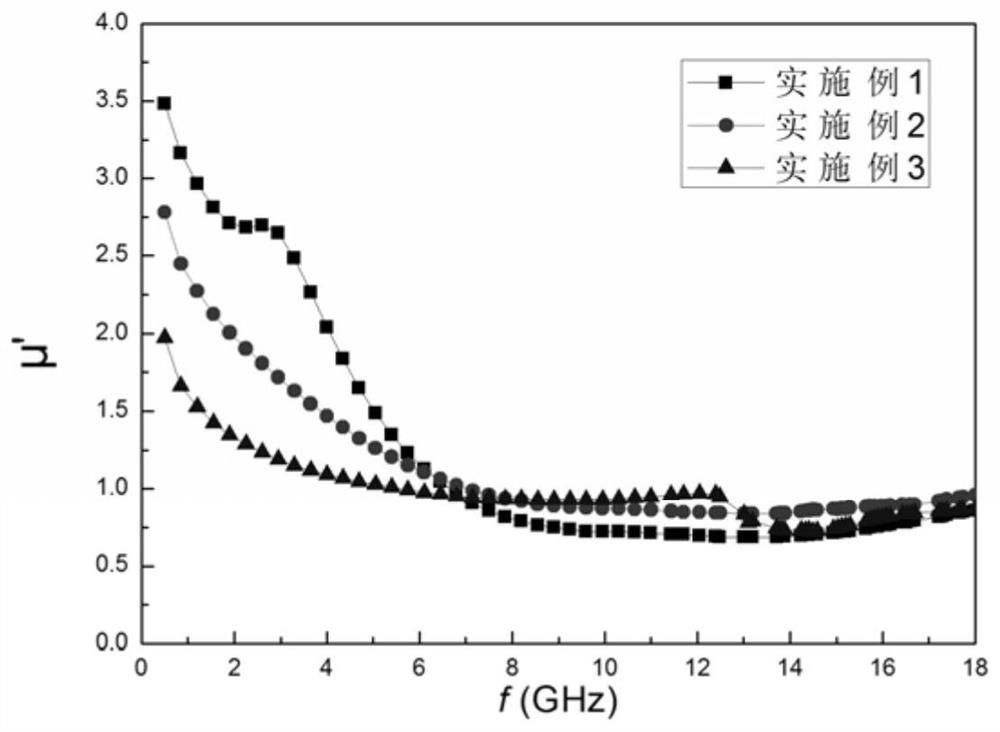

Embodiment 1

[0058] 1) Preparation of flaky FeSiAl alloy powder: the alloy powder was prepared by gas atomization, the alloy components were 85wt% Fe, 9.6wt% Si, 5.4wt% Al, and the purity of the three raw materials was higher than 99.9%. Weigh 30g of 100-mesh sieved powder, add appropriate amount of alcohol to wet mill for 30 hours according to the ratio of ball to material ratio of 20:1, dry at 60°C, and sieve with 250-mesh sieve to obtain flaky FeSiAl alloy powder.

[0059] 2) Preparation of MnZn ferrite powder: the ratio of each component is 69.4wt% Fe2O3, 15.4wt% Mn3O4, 15.2wt% ZnO. The purity of the three oxides is higher than 99.9% for Fe2O3, higher than 98.5% for Mn3O4, and higher than 99.5% for ZnO. Add appropriate amount of deionized water to the above mixture according to the ratio of ball to material ratio of 15:1, and wet mill for 3 hours. Then the mixed slurry was dried at 120°C, then heated to 950°C for pre-calcination, and kept for 2 hours. Add appropriate amount of deioni...

Embodiment 2

[0063] This implementation provides an electromagnetic wave absorbing material, the manufacturing steps of which are the same as those of Example 1, the main difference is that in step 3), the ratio of flake FeSiAl alloy powder and MnZn ferrite powder is changed to 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com