A detection method for pentachlorophenol content in paper packaging materials

A paper packaging material, pentachlorophenol technology, applied in electrochemical variables of materials, analytical materials, material analysis by electromagnetic means, etc., can solve the problems of poor anti-interference, expensive instruments, long response time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

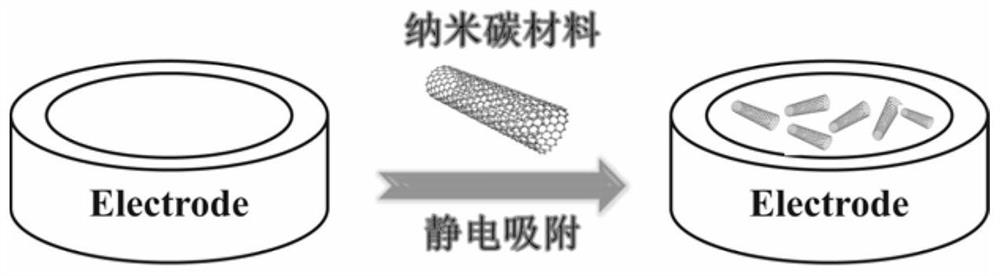

[0066] 1. Preparation of screen-printed carbon (SPCE) electrodes

[0067] The conductive silver paste was printed on the PET substrate to form electrode strips, and cured in an oven at 120° C. for 40 minutes to form a conductive silver layer. The conductive carbon paste was printed on the conductive silver layer, and cured at 71° C. for 30 minutes to form a carbon working layer. Covering insulating ink was printed on the conductive part in the conductive silver layer, and cured at 80° C. for 10 minutes to form an insulating layer. Finally, screen-printed carbon (SPCE) electrodes were prepared.

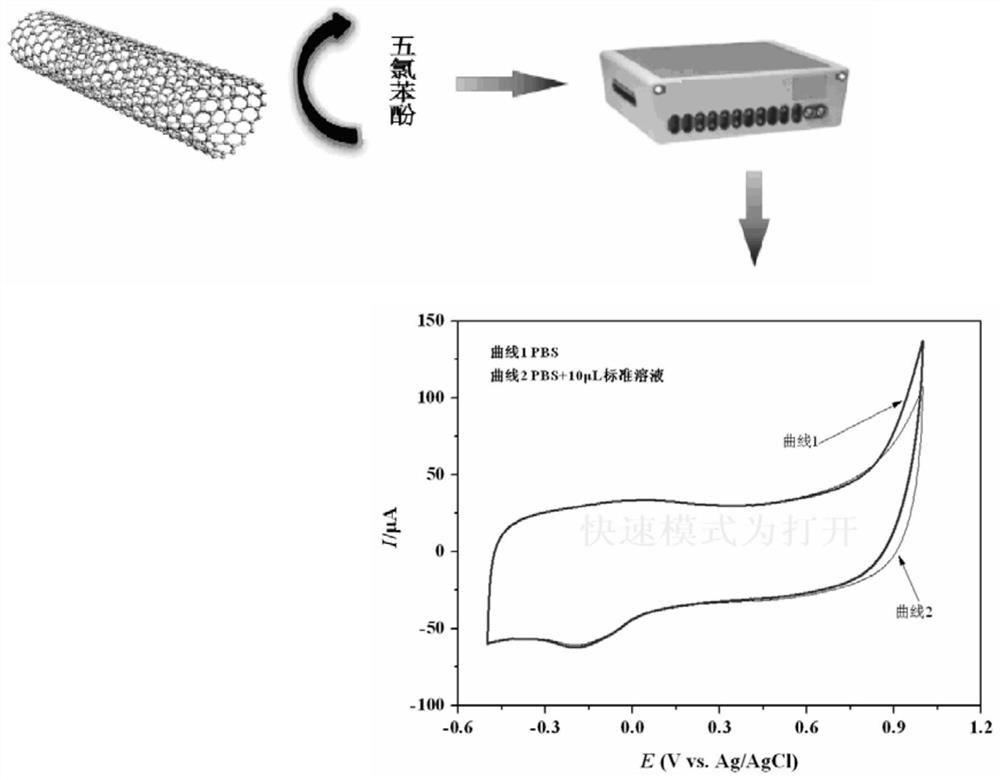

[0068] 2. Preparation of functionalized MWCNTs

[0069] Weigh 1 g of multi-walled carbon nanotubes (MWCNTs) and add it to 50 mL of 30% H 2 o 2 In the solution, ultrasound was applied for 4h to disperse the MWCNTs uniformly in the solution. Then, it was filtered with a 0.45 μm filter membrane, washed three times with ultrapure water, and dried in vacuum at 45° C. for 12 hours. Add...

Embodiment 2

[0073] 1. Preparation of functionalized monolayer graphene

[0074] Weigh 1 g of single-layer graphene and add to 50 mL of 30% H 2 o 2 In the solution, ultrasound was applied for 3 hours to uniformly disperse the single-layer graphene in the solution. Then, it was filtered with a 0.45 μm filter membrane, washed three times with ultrapure water, and dried in vacuum at 45° C. for 12 hours. Add the intermediate product of the above treatment to the mixed acid of nitric acid and sulfuric acid (HNO 3 :H 2 SO 4 =1:3), after 30 minutes of ultrasonication, reflux at 70°C for acidification reaction for 7 hours, to introduce oxygen-containing groups such as carboxyl and hydroxyl groups on the surface of single-layer graphene, to increase the water solubility of the material, and wash the product with ultrapure water until neutral , after drying in a vacuum oven at 45°C, the functionalized single-layer graphene material is obtained.

[0075] 2. Preparation of graphite electrodes ba...

Embodiment 3

[0078] 1. Preparation of functionalized nano-activated carbon

[0079] Weigh 1g of nano activated carbon and add to 50mL30%H 2 o 2 In the solution, sonicate for 5 hours, so that the nano activated carbon is evenly dispersed in the solution. Then, it was filtered with a 0.45 μm filter membrane, washed three times with ultrapure water, and dried in vacuum at 45° C. for 12 hours. Add the intermediate product of the above treatment to the mixed acid of nitric acid and sulfuric acid (HNO 3 :H 2 SO 4 =1:3), ultrasonication for 30min and then reflux at 90°C for acidification for 9h, to introduce oxygen-containing groups such as carboxyl and hydroxyl groups on the surface of nano-activated carbon to increase the water solubility of the material, and the product was washed with ultrapure water until neutral, and then After drying in a vacuum oven at 45°C, the functionalized nano-activated carbon material is obtained.

[0080] 2. Preparation of glassy carbon electrodes based on na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com