Heat stabilizer for PVC and synthesizing method of heat stabilizer

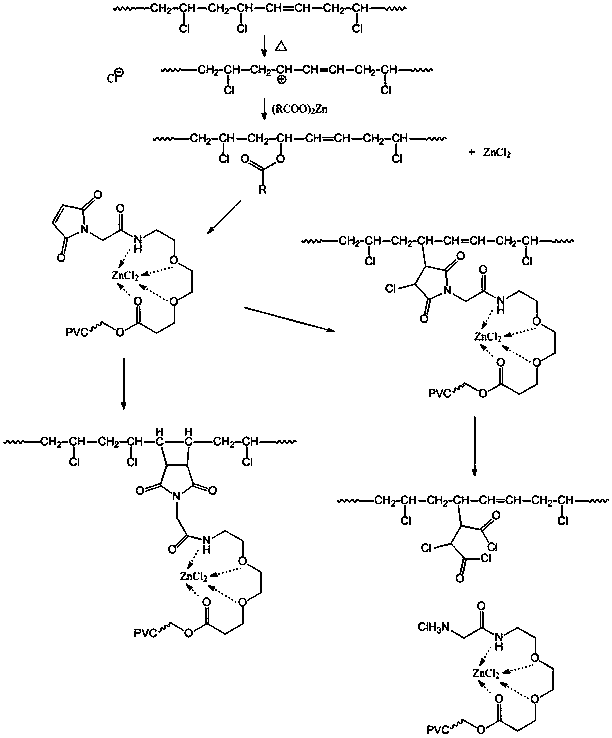

A heat stabilizer and synthesis method technology, applied in the direction of organic chemistry, can solve the problems of economic cost, complex formula, insufficient heat stabilizer, high price, etc., achieve passivation of Lewis acid, prolong thermal stability, reduce zinc burning The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

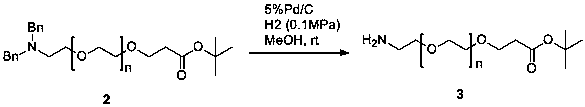

[0049] Taking R=H, n=1, M=Zn, and Ca as examples to prepare compounds 6a and 6b, it should be noted that the synthesis methods of other R substituents, ether groups and metal ions are consistent with this implementation method, and the preparation process is :

[0050] Compound 2: Dissolve hydroxyl compound 1 (26.0 g, 91 mmol) and tert-butyl acrylate (58.38 g, 455 mmol) in dichloromethane (235 ml) at room temperature at 20 degrees, and add tetra-n-butylammonium bromide (5.87 g, 18 mmol), and 50% aqueous sodium hydroxide solution (36.44 g, 455 mmol) was added dropwise with stirring. Stirring was continued for 3 hours after the addition was complete and then water (200 ml) was added. The aqueous phase was extracted with dichloromethane (2x50 ml), the organic phases were combined and washed with water (50 ml). The organic phase was dried with anhydrous magnesium sulfate and filtered, the filtrate was concentrated, added heptane (100 ml), stirred at 20°C for 1 hour, filtered off...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com