Inorganic wire material-organic polymer composite material and preparation method thereof

A composite material and polymer technology, applied in the field of materials, can solve the problems of disordered macro-scale nanorod materials, complex equipment, and difficulty in large-scale preparation of LB technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

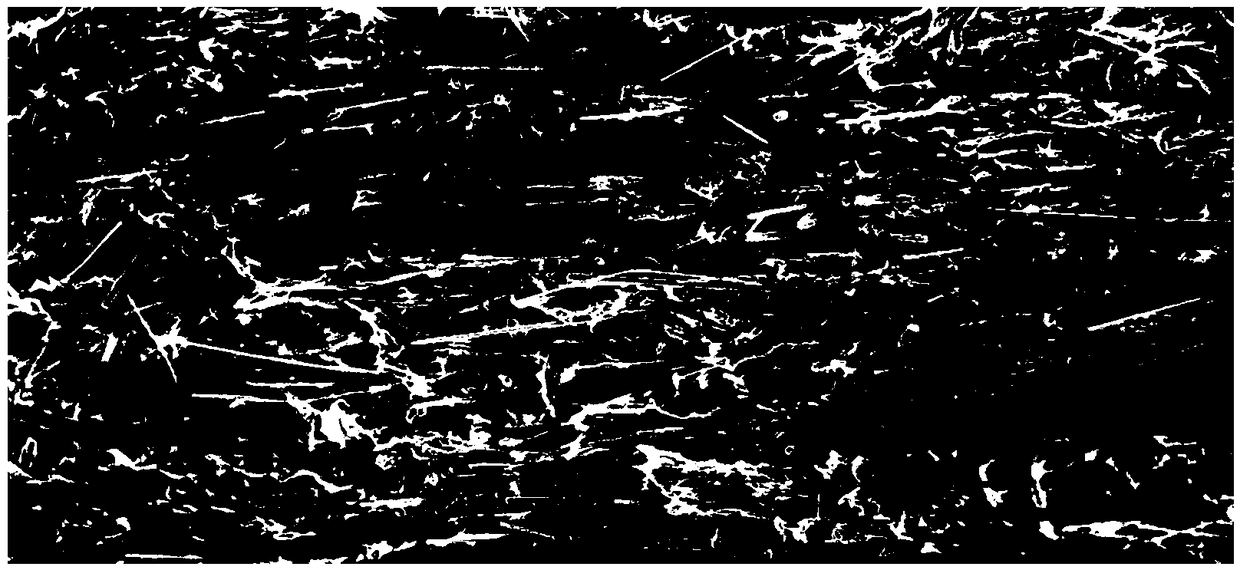

[0034] The invention provides a method for preparing an inorganic wire material-organic polymer composite material, comprising the following steps:

[0035] A) mixing an inorganic wire material with a polymer solution to obtain a mixed slurry, the inorganic wire material being selected from inorganic nanowire materials and / or inorganic microwire materials;

[0036] B) after absorbing the mixed slurry with a brush, coating the surface of the substrate according to a certain direction to obtain a substrate coated with the mixed slurry;

[0037] C) drying the substrate coated with the mixed slurry and separating it from the substrate to obtain an inorganic wire-organic polymer composite material.

[0038] In the present invention, firstly, the inorganic wire material is mixed with the polymer solution to obtain the mixed slurry.

[0039] In the present invention, the inorganic wire material can be directly mixed with the polymer solution, or the inorganic wire material can be di...

Embodiment 1

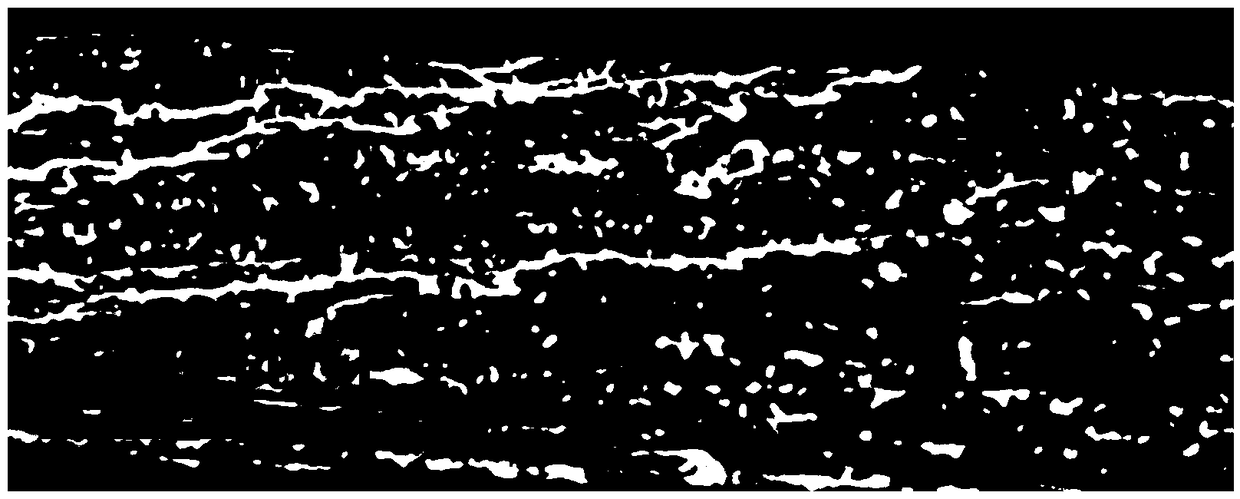

[0074] Preparation of silver-sodium alginate composite film with highly ordered arrangement of silver nanowires

[0075] Preparation of sodium alginate solution: Weigh 8.0g of sodium alginate (polymerization degree 10000, molecular weight 500000) powder in a 500mL beaker, and measure 392ml deionized water in the beaker, use mechanical stirring, 800rpm, 24h, and finally obtain a uniform 2% (20mg / mL) sodium alginate solution and put it in the refrigerator for later use. Take 10 mL of 4 mg / mL silver nanowire solution (solvent is deionized water, silver nanowire diameter is 50 nm, and length is 60 μm), and another 10 mL-2% sodium alginate solution is slowly added to the silver nanowire solution, magnetically Stir at 500rpm for 6h to become a uniform mixed solution.

[0076] Place a clean silicate glass plate (20cm*20cm*4mm) on a heater heated to 120 degrees in advance. Brush the brush (made of pig bristle bristles, the diameter of the bristles is 50-60 μm, the length is 5 cm, an...

Embodiment 2

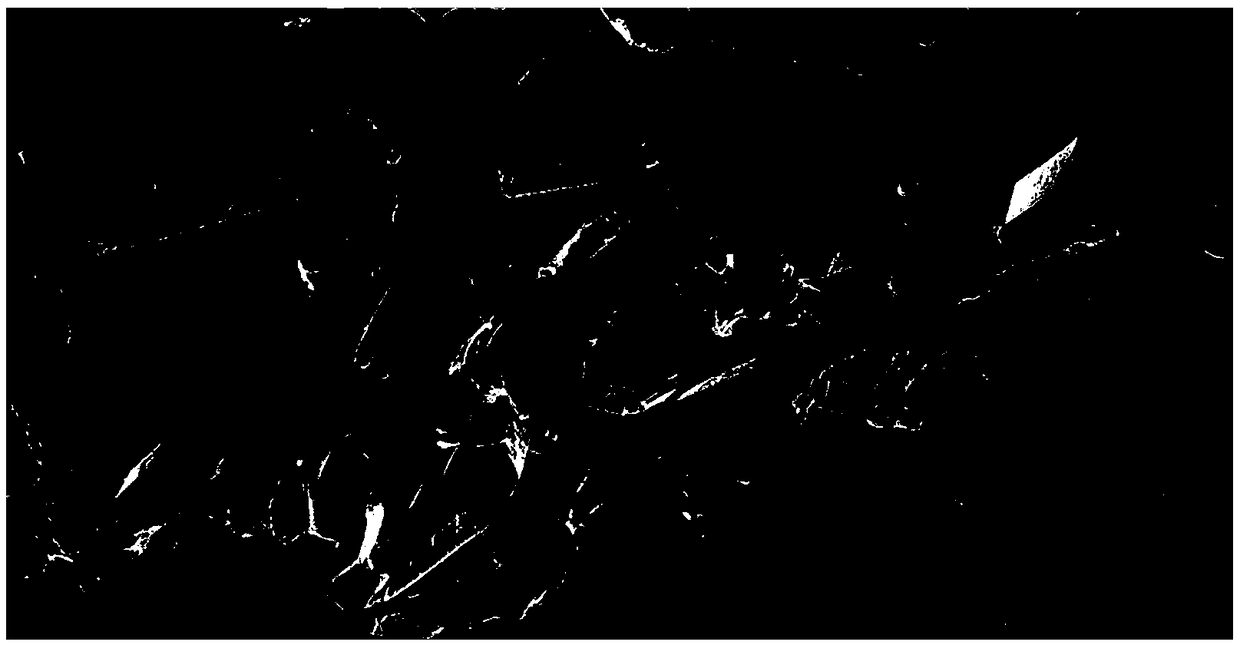

[0079] Preparation of Calcium Carbonate-Polylactic Acid Composite Films with Highly Ordered Calcium Carbonate Microwires

[0080] Disperse 3 g of polylactic acid (polymerization degree of 15,000, molecular weight of 800,000) in 27 mL of dichloromethane, magnetically stir at 500 rpm for 6 h, and obtain a clear and transparent solution, which is sealed for use. Take 1g of calcium carbonate micron wire material (2-5 μm in diameter, 80 μm in length) and disperse it in the prepared polylactic acid solution, and continue blending and stirring for 3 hours to form a uniform mixed solution.

[0081] Place a clean silicate glass plate (20cm*20cm*4mm) horizontally at room temperature. Brush the brush (made of pig bristle bristles, the diameter of the bristles is 50-60 μm, the length is 5 cm, and the density of the bristles is 1000 / cm 2 , the width of the bristles in the overall brush is 20cm, and the thickness is 1cm; the width of the brush head fixing plate is 21cm, the thickness is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com