Preparation method of sulfur modified metal hydroxide electrode material

A technology of hydroxide and electrode materials, applied in nanotechnology for materials and surface science, hybrid capacitor electrodes, nanotechnology, etc., can solve problems such as human and environmental hazards, complex production processes, and limited applications, and achieve cost-effective The effect of low cost, simple preparation process, and less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

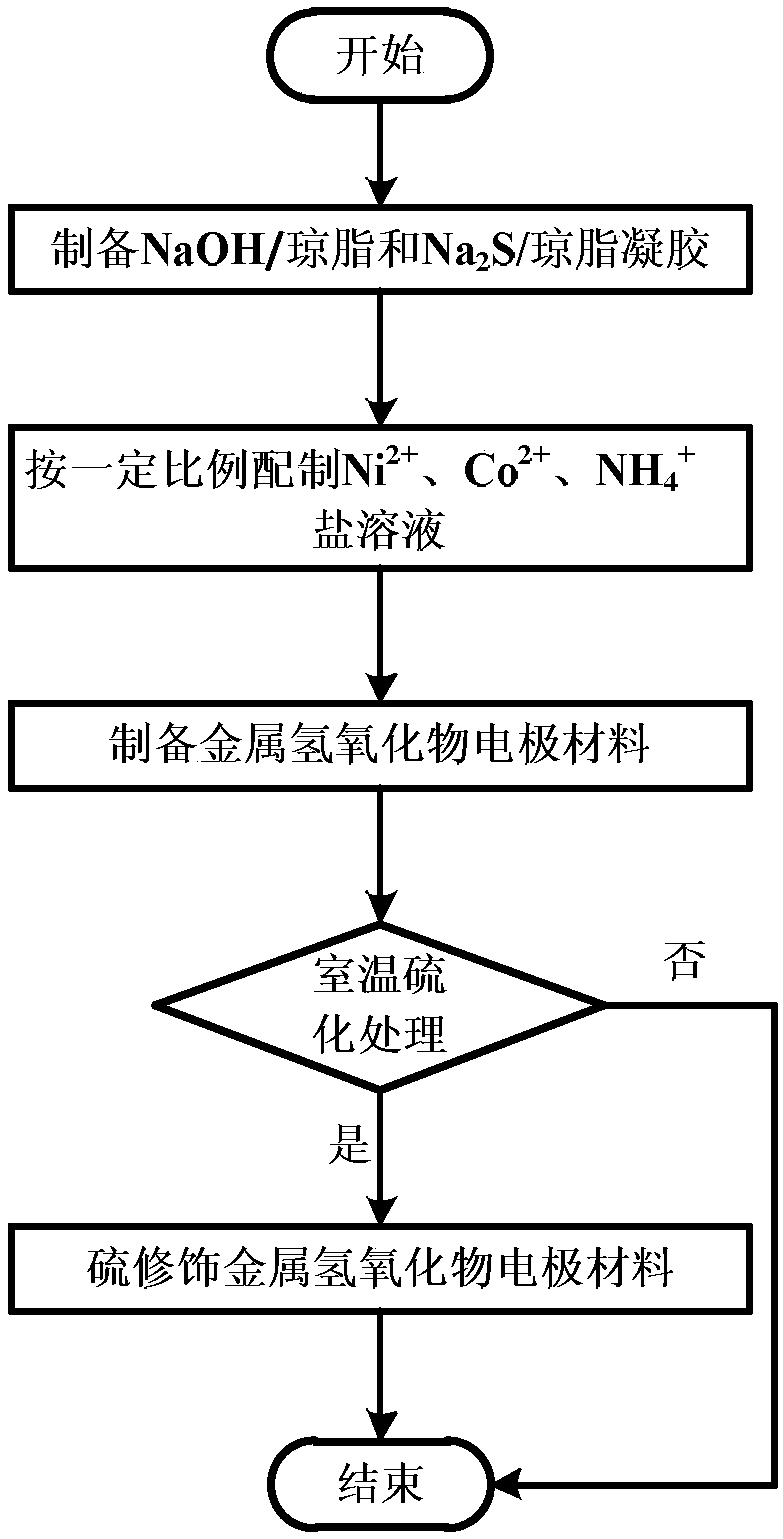

Method used

Image

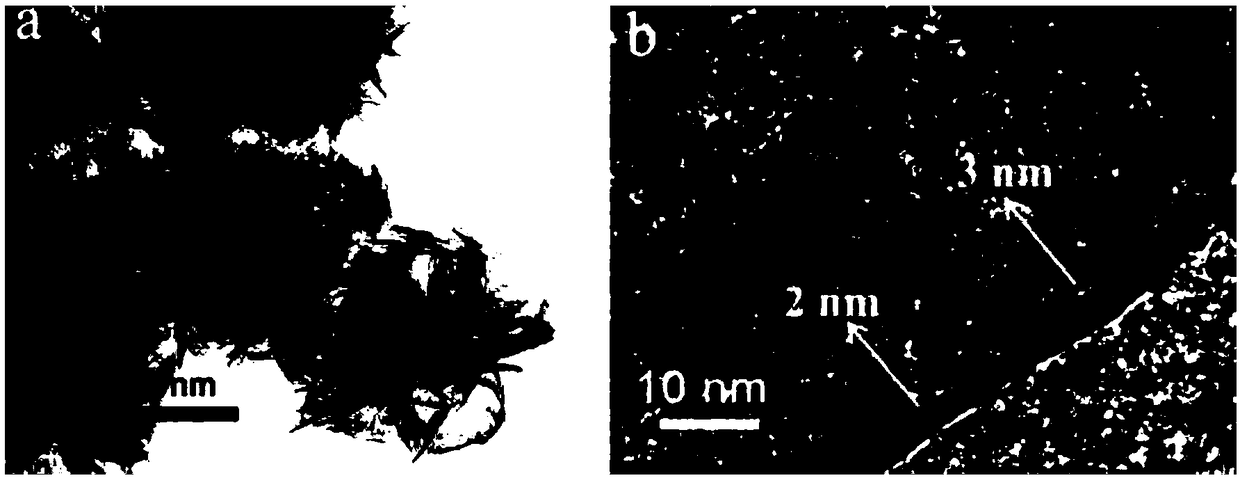

Examples

Embodiment 1

[0033] 1.1 Dissolve 0.48g of NaOH and 0.5g of natural polymer agar into 10mL of deionized water, and ultrasonically disperse the resulting mixture until a uniform light yellow suspension is obtained, and keep it in a water bath at 85°C for 10min to obtain a brown color The gel, and the gel was placed at room temperature for 4 hours, and finally completely condensed into a dark brown jelly-like solid, that is, NaOH / agar gel was obtained as an alkali source;

[0034] 1.2 Add 0.7g of agar to 20mL with a molar concentration of 0.03mol L -1 Na 2 In the S solution, ultrasonically disperse into the sodium sulfide solution, and heat it at 85°C for 10min. At room temperature, after cooling for 4h, a light green Na 2 S / agar gel, as a sulfur source;

[0035]1.3 Dissolve nickel nitrate hexahydrate, cobalt nitrate hexahydrate and ammonium chloride (0.44g, 0.71g and 0.08g) in a mixture of 15mL deionized water and 50mL N,N-dimethylformamide, and slowly Drop it into the NaOH / agar gel prepa...

Embodiment 2

[0044] Steps 1.1-1.2 are the same as steps 1.1-1.2 in Example 1;

[0045] 1.3 Dissolve nickel nitrate hexahydrate, cobalt nitrate hexahydrate and ammonium chloride (0.44g and 0.71g and 0g) in a mixture of 15mL deionized water and 50mL N,N-dimethylformamide, according to Example 1 In step 1.3, metal hydroxide is obtained;

[0046] Step 1.4 is the same as Step 1.4 in Example 1 to obtain a sulfur-modified metal hydroxide electrode material.

Embodiment 3

[0048] Steps 1.1-1.2 are the same as steps 1.1-1.2 in Example 1;

[0049] 1.3 Dissolve nickel nitrate hexahydrate, cobalt nitrate hexahydrate and ammonium chloride (0.44g, 0g and 0.08g) in a mixture of 15mL deionized water and 50mL N,N-dimethylformamide, according to Example 1 In step 1.3, metal hydroxide is obtained;

[0050] Step 1.4 is the same as Step 1.4 in Example 1 to obtain a sulfur-modified metal hydroxide electrode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com