Method for synthesizing manganese oxide attapulgite composite material through microwave method

A composite material, manganese oxide technology, applied in chemical instruments and methods, manganese oxide/hydroxide, alkali metal oxide/hydroxide, etc., can solve the problem of poor manganese oxide dispersibility, poor operability, color image Problems such as large contour noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

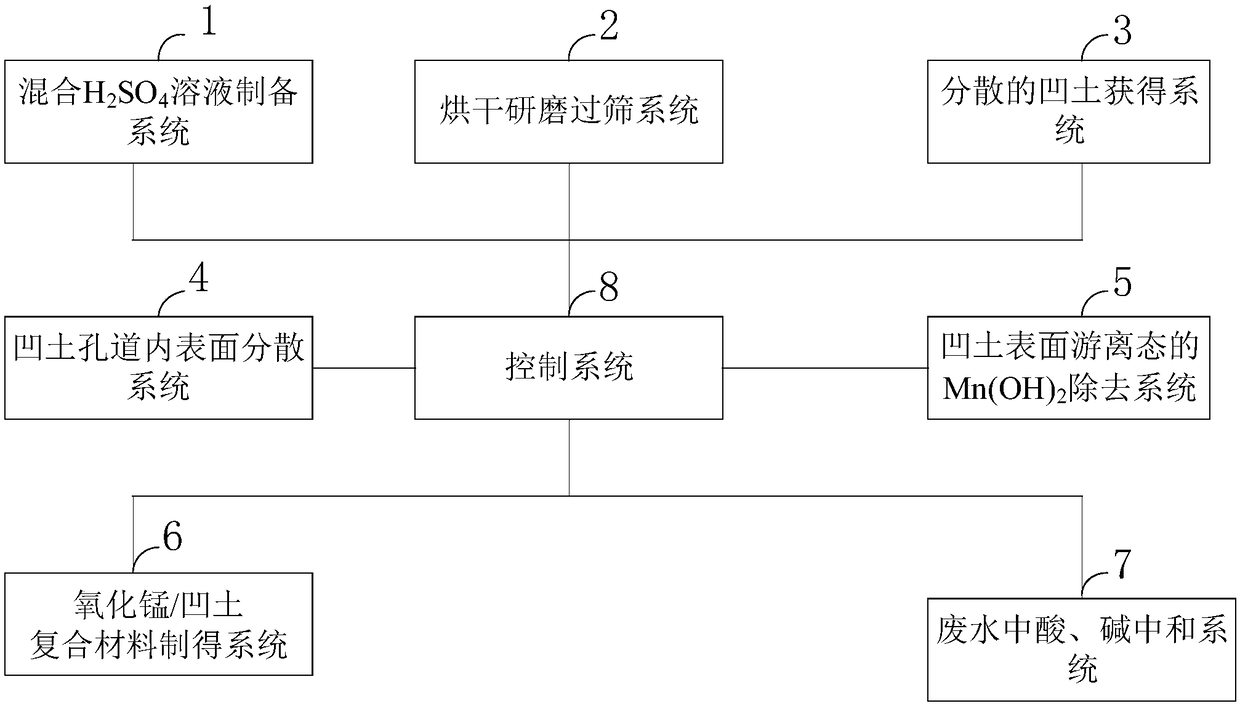

Method used

Image

Examples

Embodiment 1

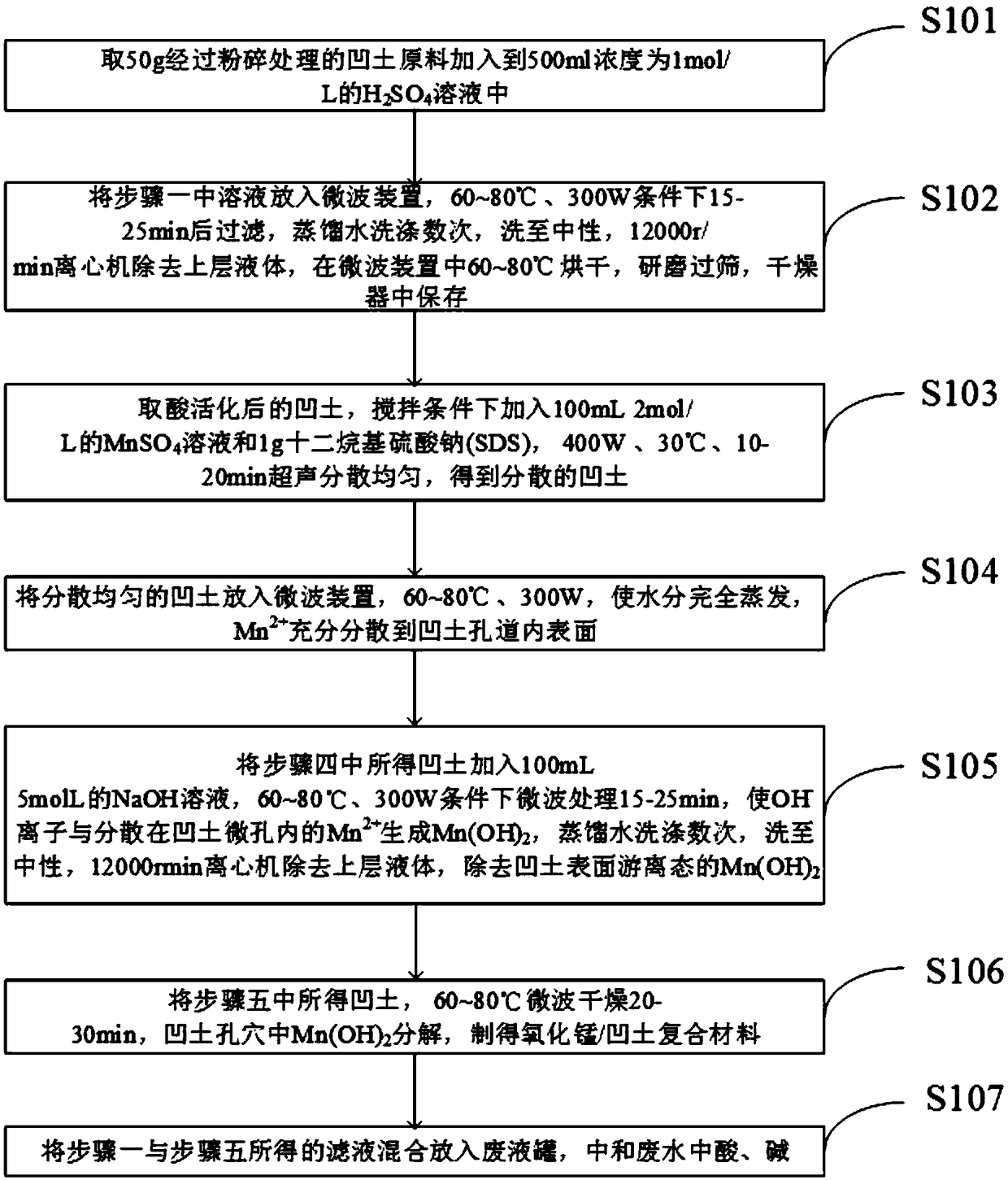

[0168] The steps of the method for synthesizing manganese oxide attapulgite composite materials by microwave method are:

[0169] Step 1: Take 50g of attapulgite raw material after crushing and add it to 500ml of H with a concentration of 1mol / L. 2 SO 4 in solution;

[0170] Step 2: Put the solution in step 1 into a microwave device, filter after 15 minutes at 60°C and 300W, wash with distilled water for several times, wash to neutrality, remove the upper liquid by centrifuge at 12000r / min, and dry at 60°C in a microwave device , ground and sieved, and stored in a desiccator;

[0171] Step 3: Take the attapulgite after acid activation, add 100mL 2mol / L MnSO under stirring condition 4 The solution and 1g of sodium dodecyl sulfate (SDS) were dispersed uniformly by ultrasonic at 400W, 30°C, 10-20min to obtain dispersed attapulgite;

[0172] Step 4: Put the evenly dispersed attapulgite into a microwave device, 60°C, 300W, so that the water is completely evaporated, Mn 2+ Full...

Embodiment 2

[0180] The steps of the method for synthesizing manganese oxide attapulgite composite materials by microwave method are:

[0181] Step 1: Take 50g of attapulgite raw material after crushing and add it to 500ml of H with a concentration of 1mol / L. 2 SO 4 in solution;

[0182] Step 2: Put the solution in step 1 into a microwave device, filter after 15-25 minutes at 80°C and 300W, wash with distilled water for several times, wash until neutral, centrifuge at 12000r / min to remove the upper layer liquid, and put it in a microwave device at 80°C Dry, grind and sieve, and store in a desiccator;

[0183] Step 3: Take the attapulgite after acid activation, add 100mL 2mol / L MnSO under stirring condition 4 The solution and 1g of sodium dodecyl sulfate (SDS) were uniformly dispersed by ultrasonic at 400W, 30°C, 20min to obtain dispersed attapulgite;

[0184] Step 4: Put the evenly dispersed attapulgite into the microwave device, 80 ℃, 300W, make the water evaporate completely, Mn 2+ ...

Embodiment 3

[0192] The steps of the method for synthesizing manganese oxide attapulgite composite materials by microwave method are:

[0193] Step 1: Take 50g of attapulgite raw material after crushing and add it to 500ml of H with a concentration of 1mol / L. 2 SO 4 in solution;

[0194] Step 2: Put the solution in step 1 into a microwave device, filter it for 15-25 minutes at 70°C and 300W, wash with distilled water for several times until neutral, centrifuge at 12000r / min to remove the upper layer liquid, and put it in a microwave device at 70°C Dry, grind and sieve, and store in a desiccator;

[0195] Step 3: Take the attapulgite after acid activation, add 100mL 2mol / L MnSO under stirring condition 4 The solution and 1g of sodium dodecyl sulfate (SDS) were uniformly dispersed by ultrasonic at 400W, 30°C, 15min to obtain dispersed attapulgite;

[0196] Step 4: Put the evenly dispersed attapulgite into the microwave device, 70 ℃, 300W, make the water evaporate completely, Mn 2+ Fully...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com