Preparation method of high-binding type antioxidant edible membrane material

A combined, anti-oxidative technology, applied in the field of food packaging, can solve problems such as oxidative deterioration and corruption, and achieve the effects of enhanced solubility, improved stability, and improved solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

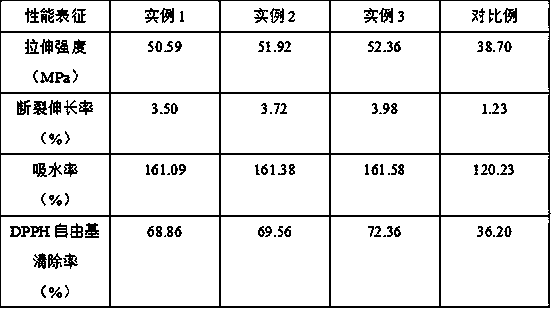

Examples

example 1

[0023] Take Polygonatum Polygonatum and crush it, grind it through an 80-mesh sieve and dry it at 75°C for 2 hours, collect the dried Polygonatum Polygonatum particles and add the dried Polygonatum Polygonatum particles to a pH of 7.0 with disodium hydrogen phosphate-diphosphate Extract in sodium hydrogen buffer solution at 0°C for 20 hours, collect the extract and vacuum freeze-dry, collect the granules to obtain crude protein granules; add the crude protein granules to deionized water at a mass ratio of 1:10, stir and mix Add dropwise 5% sodium hydroxide to adjust the pH to 8.5 to obtain an alkalized solution, then add succinic anhydride to the alkalized solution at a mass ratio of 1:15, and adjust the pH to 8.5 with 1 mol / L sodium hydroxide solution , reacted at room temperature for 2 hours, filtered and vacuum freeze-dried, and ground through a 100-mesh sieve to obtain a modified powder; according to a mass ratio of 1:15, the modified powder was added to deionized water, st...

example 2

[0025]Take Polygonatum Polygonatum and crush it, grind it through an 80-mesh sieve and dry it at 78°C for 2.5 hours, collect the dried Polygonatum Polygonatum particles and add the dried Polygonatum Polygonatum particles to a pH of 7.0 with disodium hydrogen phosphate-phosphoric acid Sodium dihydrogen buffer solution, leaching at 3°C for 22 hours, collecting the extract and vacuum freeze-drying, collecting the particles to obtain crude protein particles; according to the mass ratio of 1:10, add the crude protein particles into deionized water, stir Mix and add dropwise 5% sodium hydroxide to adjust the pH to 8.5 to obtain an alkalized solution, then add succinic anhydride to the alkalized solution at a mass ratio of 1:15, and adjust the pH to 8.5 with 1mol / L sodium hydroxide solution. 8.5, after reacting at room temperature for 2 hours, filter and vacuum freeze-dry, grind through a 100-mesh sieve to obtain a modified powder; according to a mass ratio of 1:15, add the modified...

example 3

[0027] Take Polygonatum Polygonatum and crush it, grind it through an 80-mesh sieve and dry it at 80°C for 3 hours, collect the dried Polygonatum Polygonatum particles and add the dried Polygonatum Polygonatum particles to a pH of 7.0 with disodium hydrogen phosphate-diphosphate Extract in sodium hydrogen buffer solution at 5°C for 24 hours, collect the extract and vacuum freeze-dry, collect the granules to obtain crude protein granules; add the crude protein granules to deionized water at a mass ratio of 1:10, stir and mix Add dropwise 5% sodium hydroxide to adjust the pH to 8.5 to obtain an alkalized solution, then add succinic anhydride to the alkalized solution at a mass ratio of 1:15, and adjust the pH to 8.5 with 1 mol / L sodium hydroxide solution , reacted at room temperature for 3 hours, filtered and vacuum freeze-dried, and ground through a 100-mesh sieve to obtain a modified powder; according to a mass ratio of 1:15, the modified powder was added to deionized water, st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com