A kind of high-permeability medical tape base material and preparation method thereof

A base material and adhesive tape technology, applied in pulp beating method, pulp beating/refining method, synthetic cellulose/non-cellulose material pulp/paper, etc., can solve poor anti-allergic, high manufacturing cost, poor product stability, etc. problems, to achieve the effect of huge demand gap, broad market prospects and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

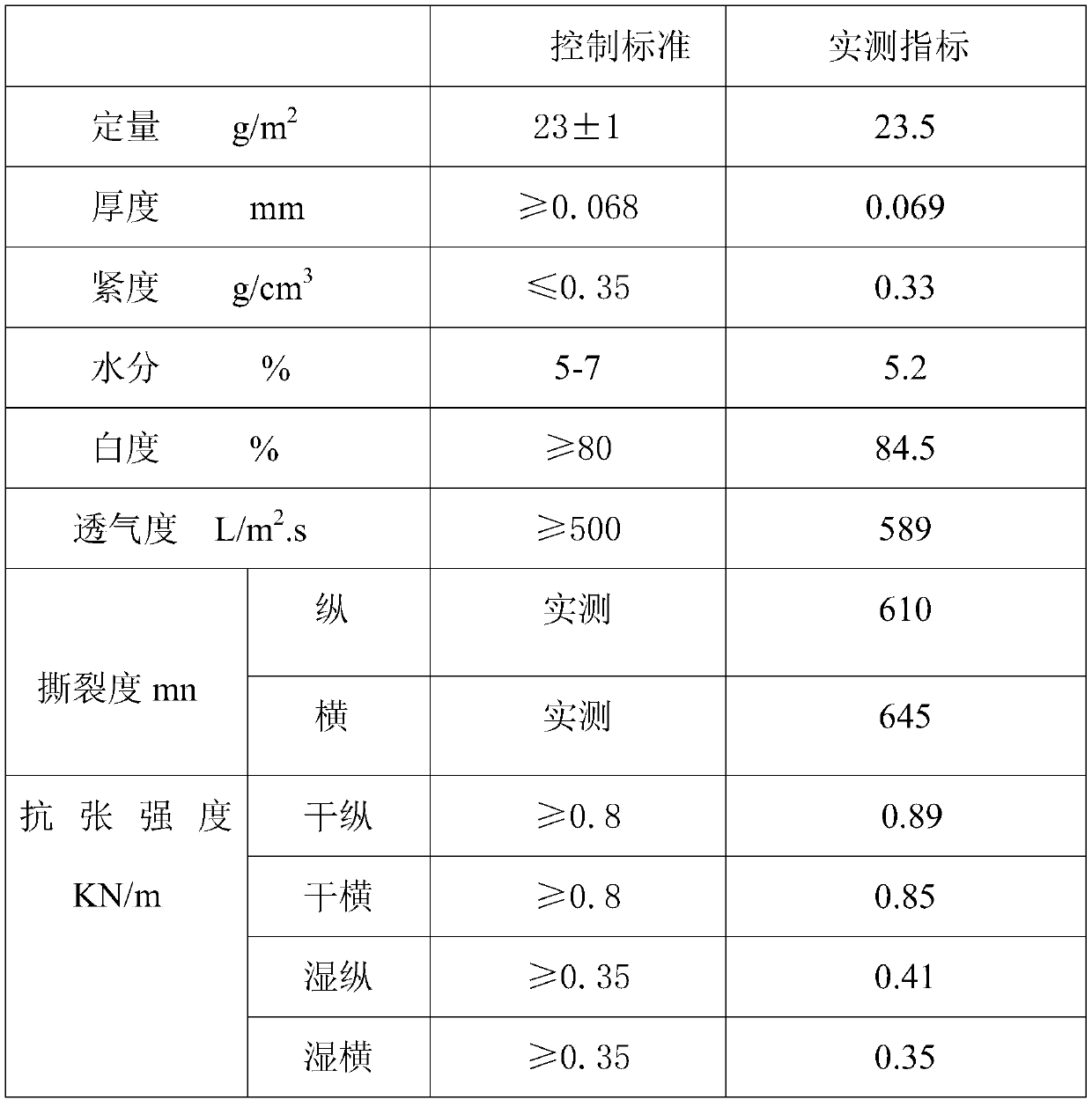

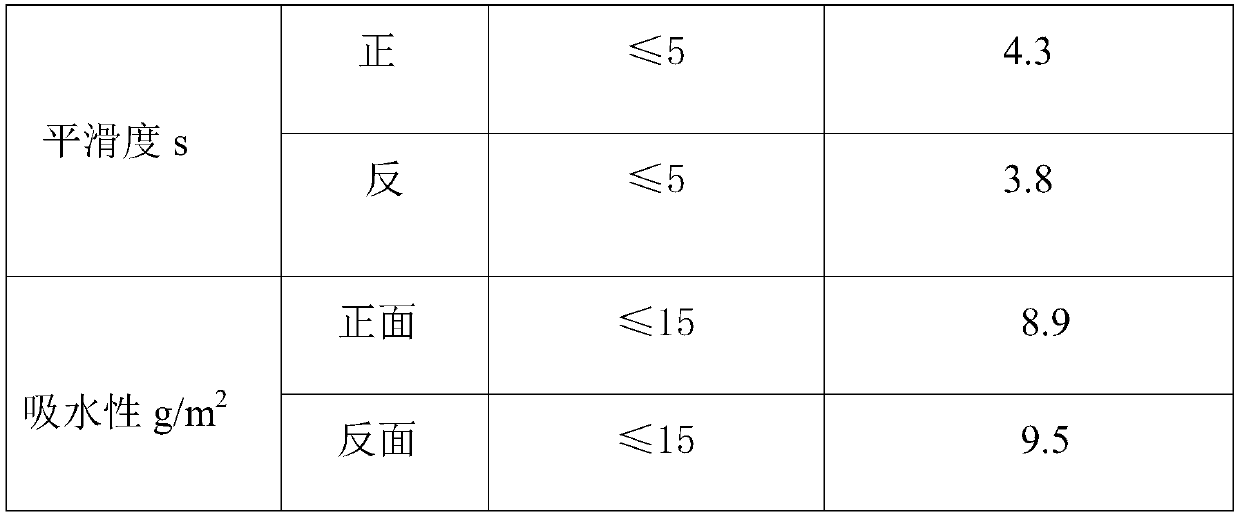

Examples

Embodiment 1

[0028] A high-permeability medical tape base material, including the following components, wood pulp fiber, polyester fiber, low-melt fiber, AKD neutral sizing solution and wet strength agent, the low-melt fiber is ES low-melt two-component composite fiber and A mixture of two types of low-melt PVA fibers; each component is evenly distributed and bonded together by bonding and melting between fibers. ES fiber is a composite fiber with a two-component sheath-core structure. The cortex has a low melting point and good flexibility, while the core has a high melting point and high strength. After heat treatment, a part of the cortex melts and acts as a bond, while the rest remains in the fiber state. At the same time, it has the characteristics of small thermal shrinkage rate. The fiber is especially suitable for the production of hygienic materials, thermal insulation fillers, filter materials and other products by the hot air penetration process.

[0029] The components include...

Embodiment 2

[0047] A high-permeability medical tape base material, including the following components, wood pulp fiber, polyester fiber, low-melt fiber, AKD neutral sizing solution and wet strength agent, wherein the low-melt fiber is selected from ES low-melt two-component composite fiber ; Each component is evenly distributed and bonded together by adhesion and melting between fibers. ES fiber is a composite fiber with a two-component sheath-core structure. The cortex has a low melting point and good flexibility, while the core has a high melting point and high strength. After heat treatment, a part of the cortex melts and acts as a bond, while the rest remains in the fiber state. At the same time, it has the characteristics of small thermal shrinkage rate. The fiber is especially suitable for the production of hygienic materials, thermal insulation fillers, filter materials and other products by the hot air penetration process.

[0048] The components include the following parts by we...

Embodiment 3

[0066] A high-permeability medical tape base material, including the following components, wood pulp fiber, polyester fiber, low-melt PVA fiber, AKD neutral sizing solution and wet strength agent, each component is evenly distributed and bonded through the fibers and melt together.

[0067] The components include the following parts by weight: 50 parts of wood pulp fiber, 40 parts of polyester fiber and 10 parts of low-melt PVA fiber. Wherein the wood pulp fiber selects coniferous wood pulp fiber with a fiber length of 2 to 5 mm. The polyester fiber is selected from polyester fibers with a fineness of 0.5D to 1D and a length of 4 to 10mm. The low-melt PVA fiber is selected from low-melt PVA fibers with a fineness of 0.5D-1D, a length of 4-10mm, and a melting point of 70-90°C. PVA fiber has unique strong adhesion, film flexibility, smoothness, oil resistance, solvent resistance, protective colloid, gas barrier, and abrasion resistance.

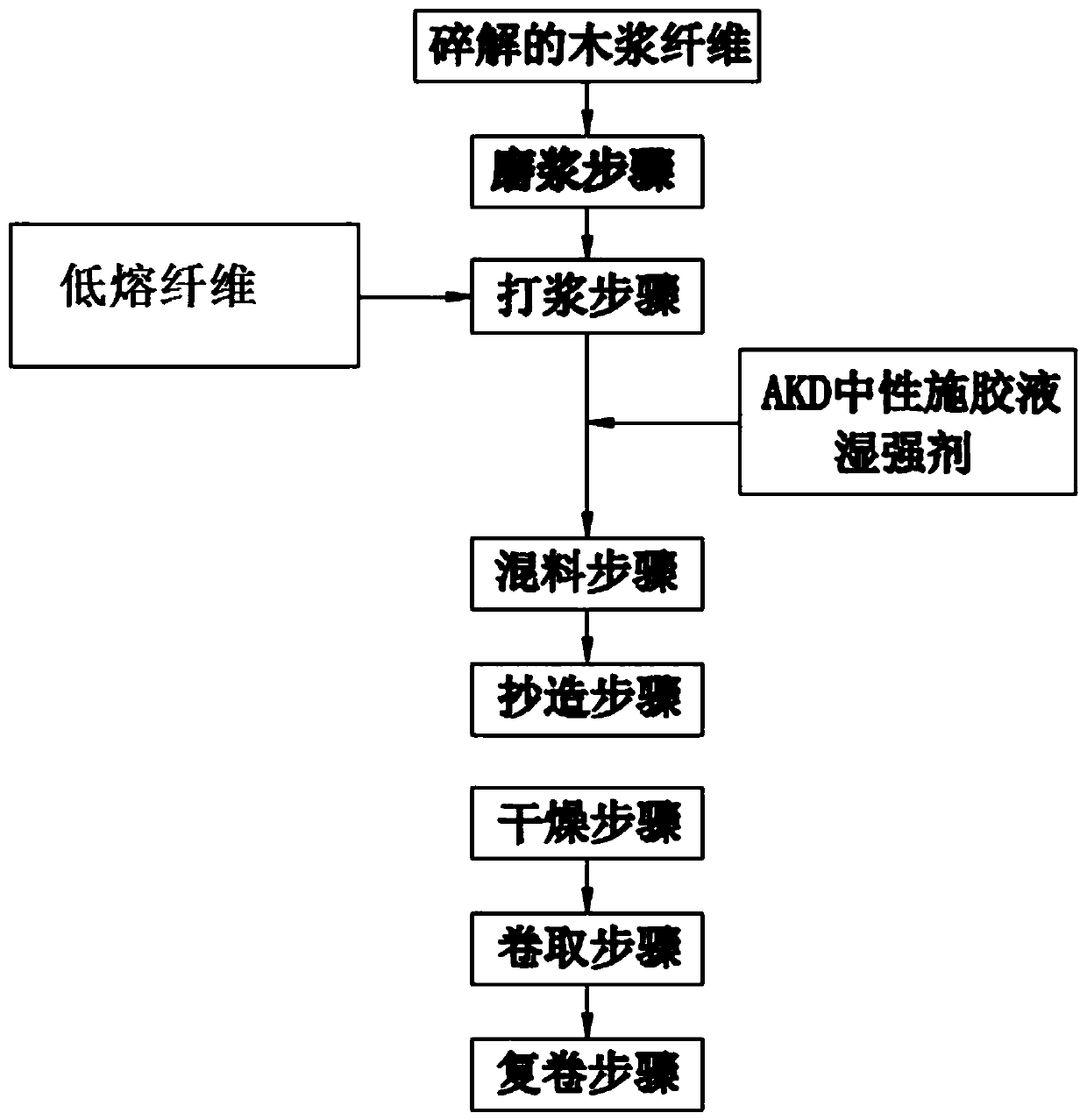

[0068] Such as figure 1 As shown, a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com