Preparation method and application of palladium nano particle-modified indium oxide nanosheet composite material

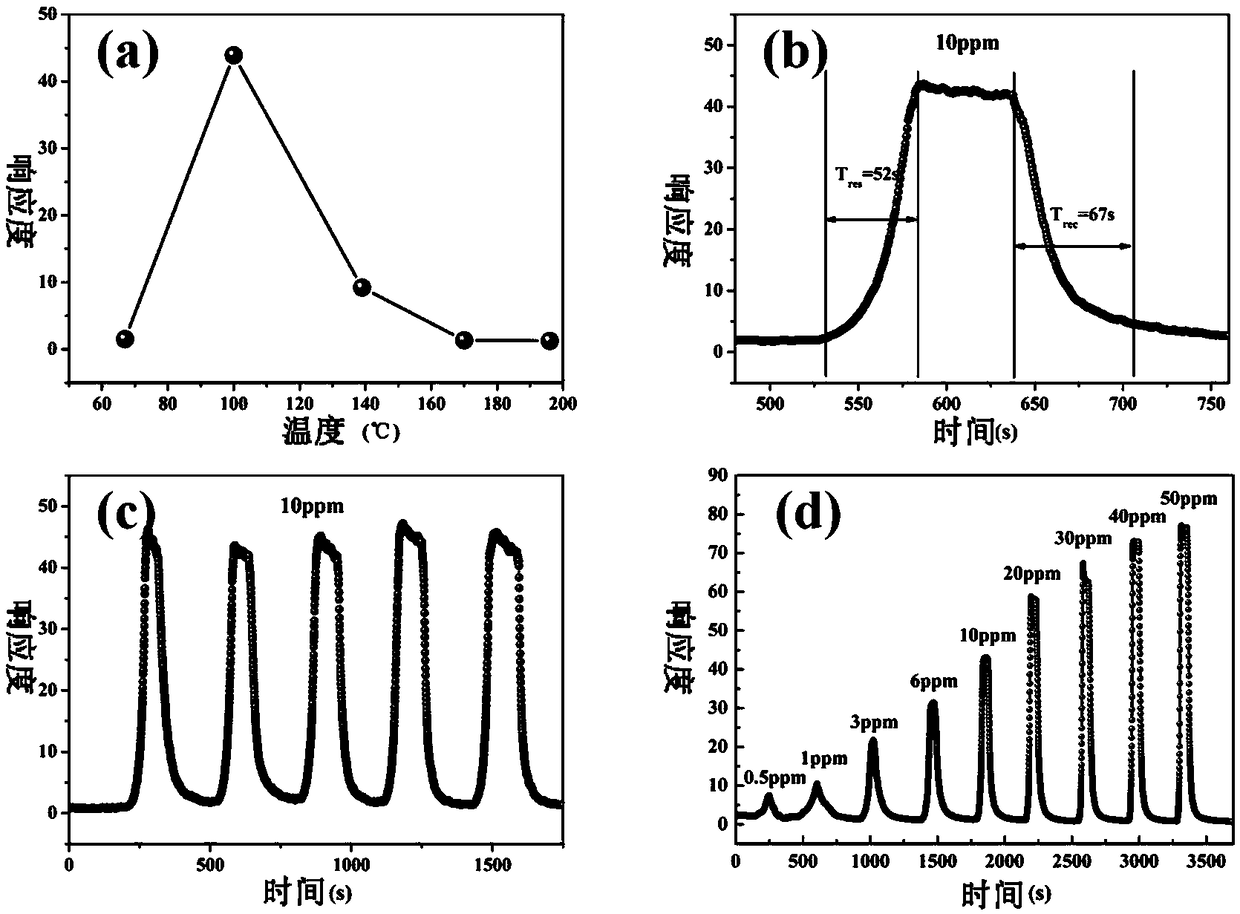

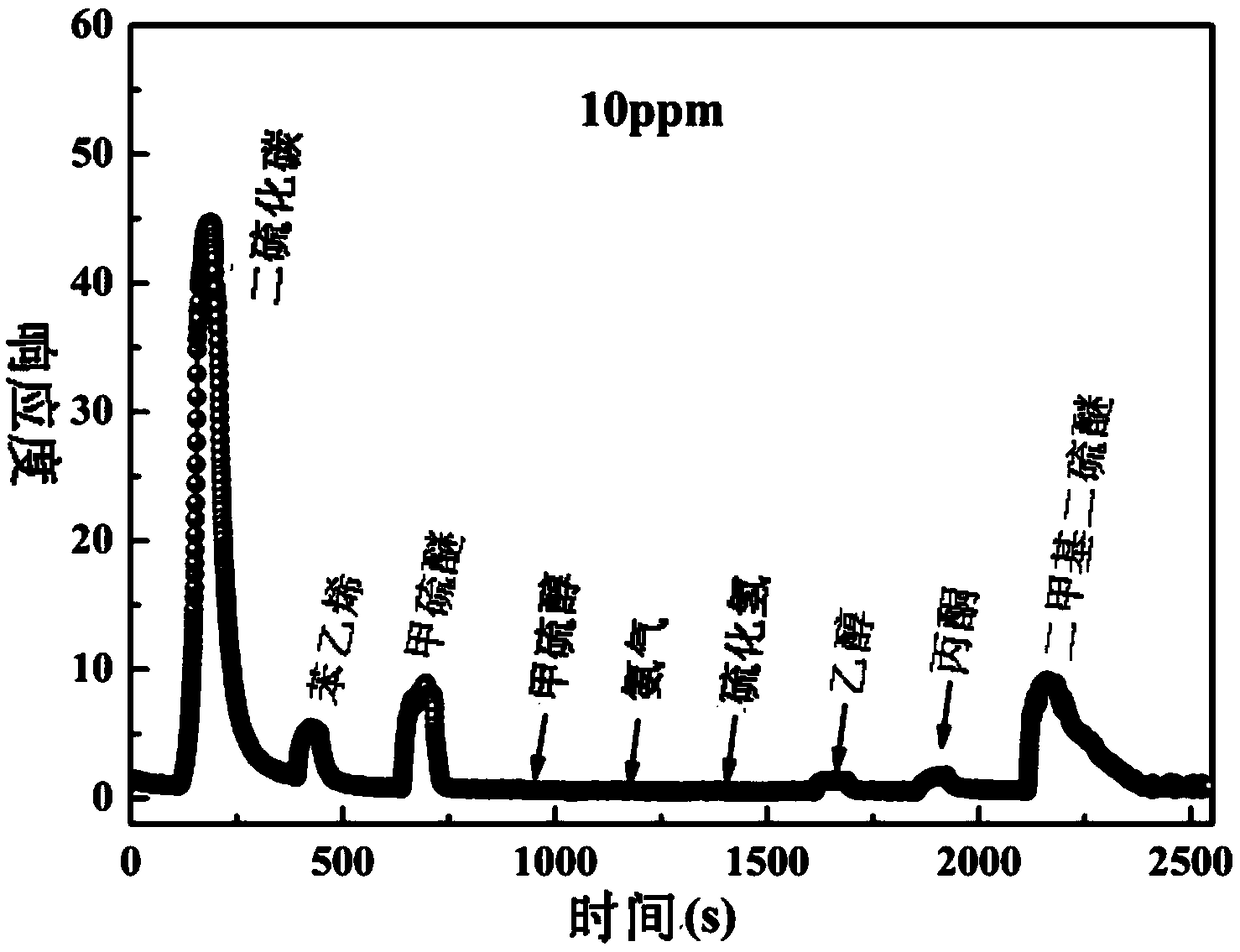

A palladium nanoparticle and composite material technology, which is applied in the field of ultra-thin indium oxide nanosheet composite material and its preparation, can solve the problems of inability to perform real-time on-site monitoring, poor detection sensitivity and selectivity, and expensive detection equipment, and achieves good gas sensitivity. Characteristic, ultra-sensitive and highly selective detection, the effect of low detection cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

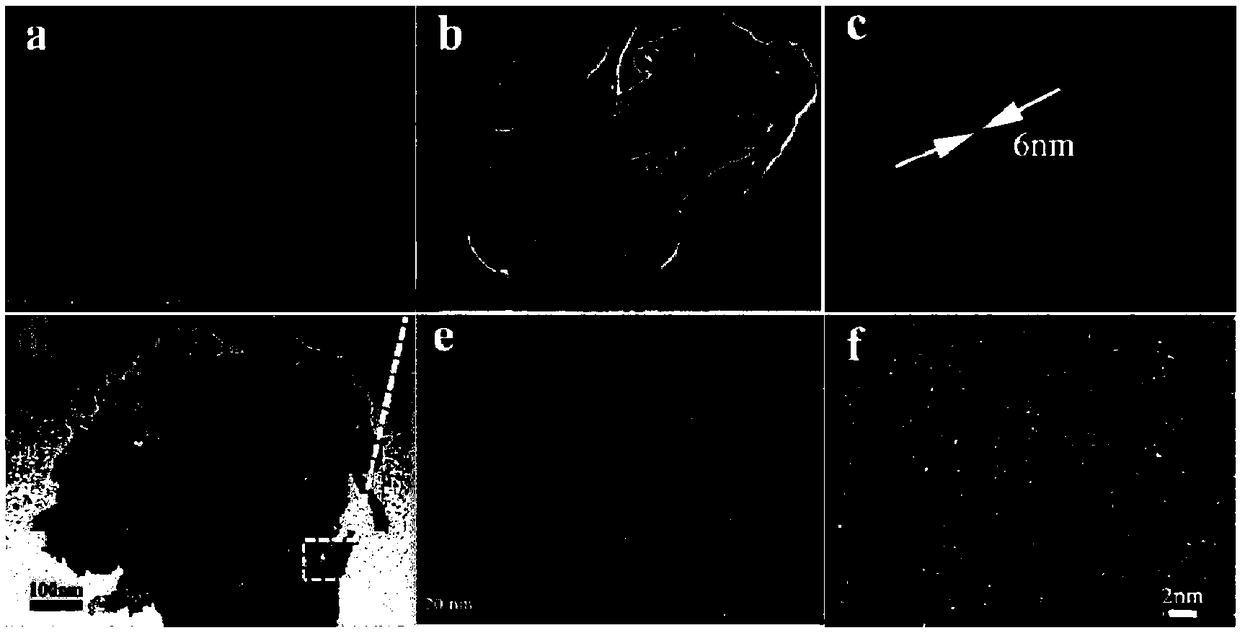

[0025] A palladium nanoparticle-modified indium oxide nanosheet composite material, the preparation method of which may comprise the following steps:

[0026] Step A, according to the weight ratio of indium nitrate: resorcinol: N, N-dimethylformamide: acetone=1:0.1~0.8:50~150:50~100, indium nitrate, resorcinol, Mix N,N-dimethylformamide and acetone together, stir for 0.1-2 hours, add deionized water, then place in a closed environment at 80-200°C for 0.5-24 hours, and then perform solid-liquid separation and washing. In this way, three-dimensional network-like indium-based organic framework nanosheets are prepared. Wherein, the amount of the deionized water is 0.001-0.1 times the mass of the indium nitrate.

[0027] Step B, dispersing the indium-based organic framework nanosheets with a three-dimensional network structure into acetone, and controlling its concentration to 0.05-2.5 mg / mL, stirring for 10-60 min, then adding palladium nitrate, and stirring for 1-24 h, Then sol...

Embodiment 1

[0039] A palladium nanoparticle-modified indium oxide nanosheet composite material, the preparation method of which comprises the following steps:

[0040] Step a1, according to the weight ratio of indium nitrate:resorcinol:N,N-dimethylformamide:acetone=1:0.1~0.8:50~150:50~100, indium nitrate, resorcinol, Mix N,N-dimethylformamide and acetone together, stir for 1 hour, add an appropriate amount of deionized water, then place it in a closed environment at 150°C for 4 hours, and then perform solid-liquid separation and washing to obtain a three-dimensional Indium-based organic framework nanosheets with network structure.

[0041] Step b1, disperse 50 mg of the indium-based organic framework nanosheets with a three-dimensional network structure into 30 mL of acetone, stir for 30 min, then add 15 mL of palladium nitrate with a concentration of 0.2 mg / mL, and stir for 10 h, then perform solid-liquid separation and Washing, thereby preparing palladium ion-modified three-dimensional...

Embodiment 2

[0049] A palladium nanoparticle-modified indium oxide nanosheet composite material, the preparation method of which comprises the following steps:

[0050] Step a2, according to the weight ratio of indium nitrate:resorcinol:N,N-dimethylformamide:acetone=1:0.1~0.8:50~150:50~100, indium nitrate, resorcinol, Mix N,N-dimethylformamide and acetone together, stir for 2 hours, add an appropriate amount of deionized water, and then place it in a closed environment at 150°C for 6 hours, and then perform solid-liquid separation and washing to obtain a three-dimensional Indium-based organic framework nanosheets with network structure.

[0051] Step b2, disperse 50 mg of the indium-based organic framework nanosheets with a three-dimensional network structure into 40 mL of acetone, stir for 30 min, then add 15 mL of palladium nitrate with a concentration of 0.15 mg / mL, and stir for 10 h, then perform solid-liquid separation and Washing, thereby preparing palladium ion-modified three-dimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com