Modified carbon nitride photocatalyst, preparation method thereof, and method for synthesizing xylosic acid by photocatalytic oxidation of xylose

A photocatalytic oxidation and catalyst technology, which is applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of difficult separation of by-products, strict requirements for experimental conditions, and difficult conditions to control, etc. Mild conditions, safe synthesis method, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

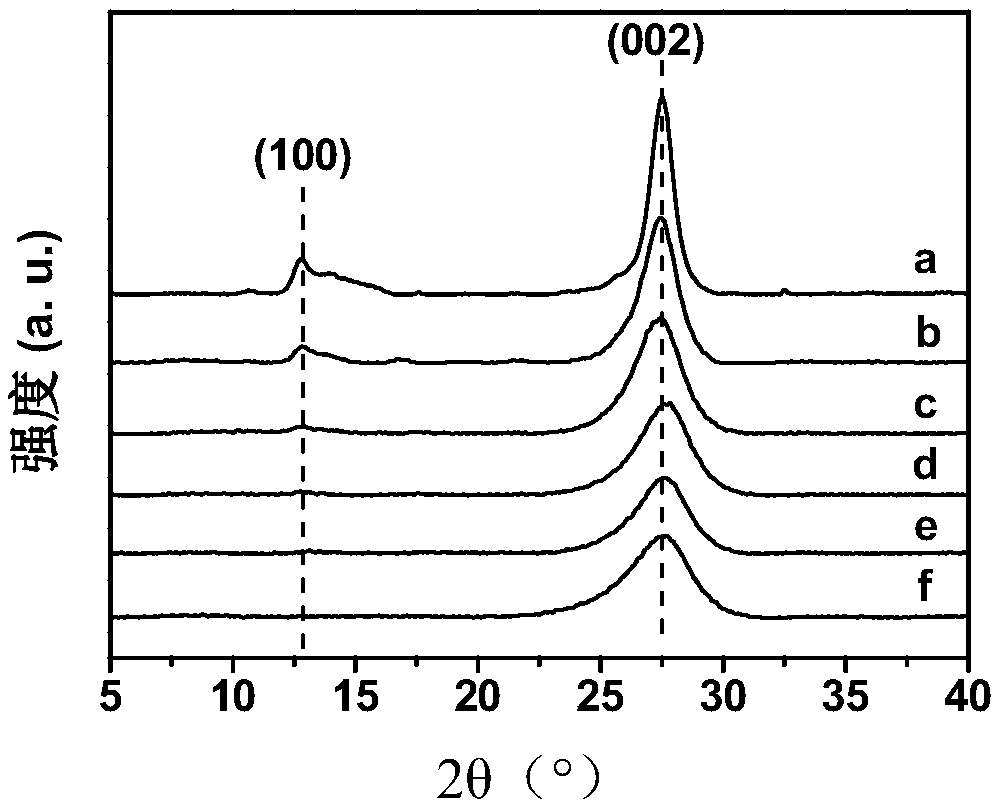

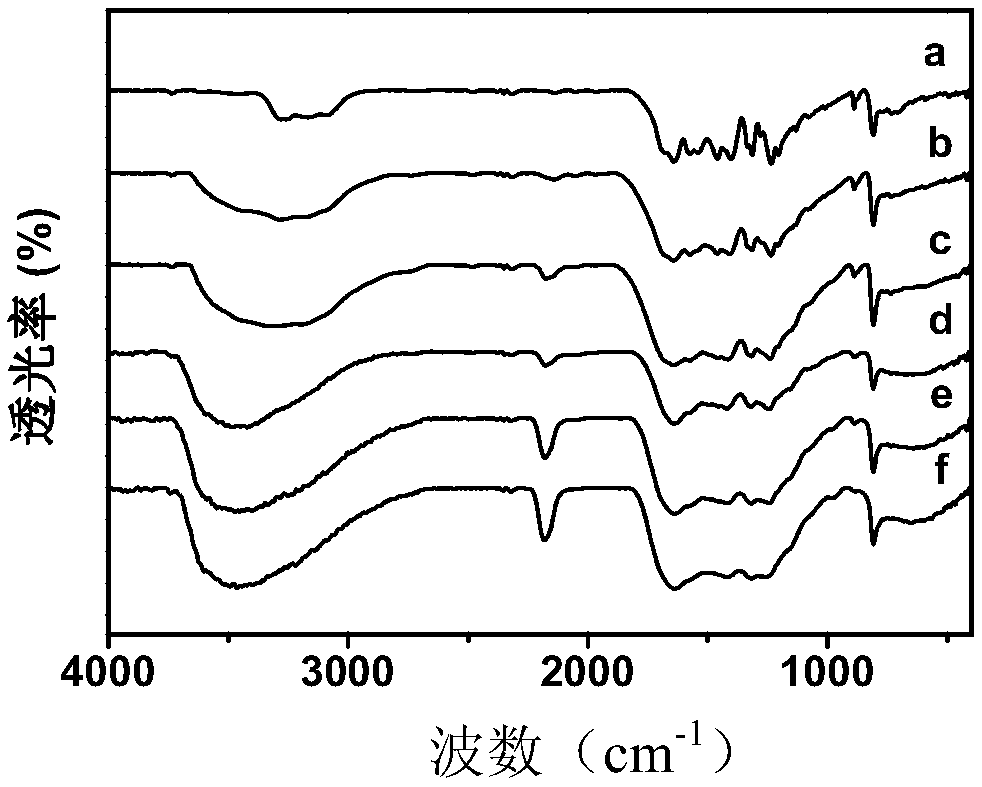

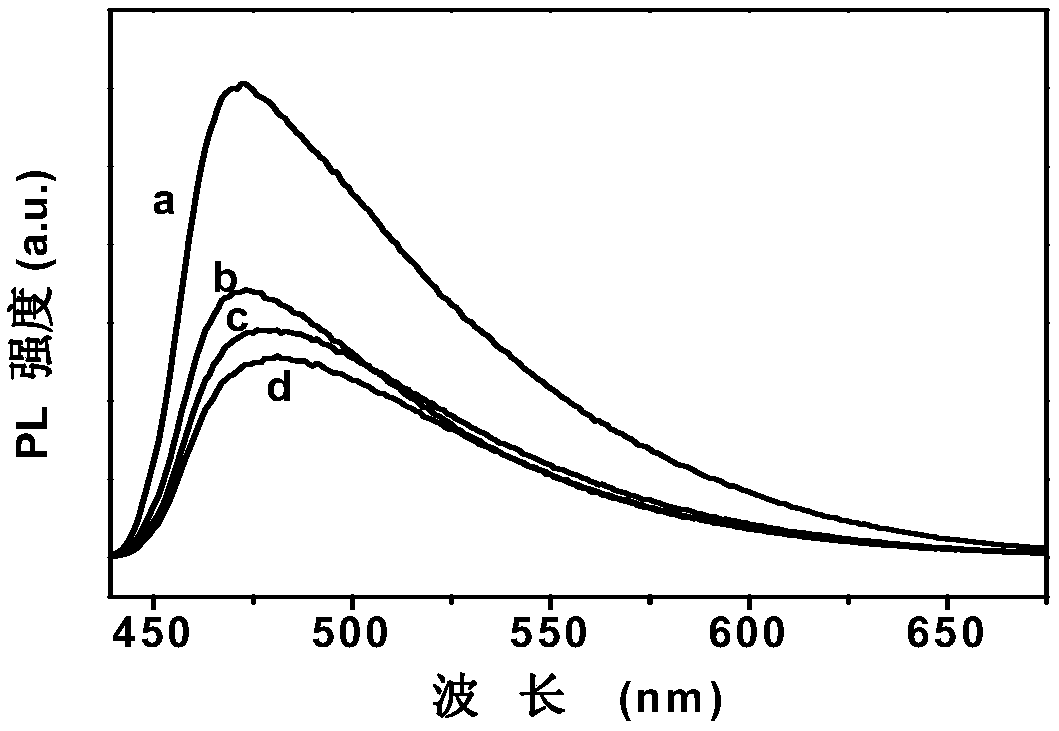

[0053] A preparation method of modified carbon nitride photocatalyst, comprising the following steps:

[0054] (1) Add 10g of nitrogen-containing organic precursor urea into 30mL of water, and then add 0, 0.005g, 0.01g, 0.05g, 0.1g, 0.5g, 1g of chlorine-containing salt compound AlCl 3 ·6H 2 O, after stirring evenly at room temperature, heat and evaporate water at 60°C, grind thoroughly to obtain a solid product;

[0055] (2) calcining the solid product of step (1) at 550° C. for 4 hours to obtain a calcined product;

[0056] (3) The calcined product of step (2) was treated with 20% hydrofluoric acid for 10 hours to remove metal ions, then centrifuged, washed with water, and dried at 80°C for 12 hours to obtain g-C 3 N x Photocatalytic material (g-C 3 N x -n, n=0, 0.005, 0.01, 0.05, 0.1, 0.5, 1.0).

Embodiment 2

[0058] A preparation method of modified carbon nitride photocatalyst, comprising the following steps:

[0059] The nitrogen-containing organic precursor of step (1) is replaced by thiourea, AlCl 3 ·6H 2 The consumption of O is changed into 1g, and all the other conditions are with embodiment 1;

[0060] Step (2), step (3) are the same as embodiment 1.

Embodiment 3

[0062] A preparation method of modified carbon nitride photocatalyst, comprising the following steps:

[0063] The nitrogen-containing organic precursor of step (1) is replaced by dicyandiamide, AlCl 3 ·6H 2 The consumption of O is changed into 1g, and all the other conditions are with embodiment 1;

[0064] Step (2), step (3) are the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com