A kind of preparation method of high tensile elastic cellulose film

A stretching elastic, cellulose film technology, applied in the field of preparation of high stretch elastic cellulose film, can solve the problems of inability to meet the requirements of packaging use, rupture of cellulose film, poor tensile elasticity of cellulose film, etc. The effect of oily surface, improved solubility and degradability, high biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

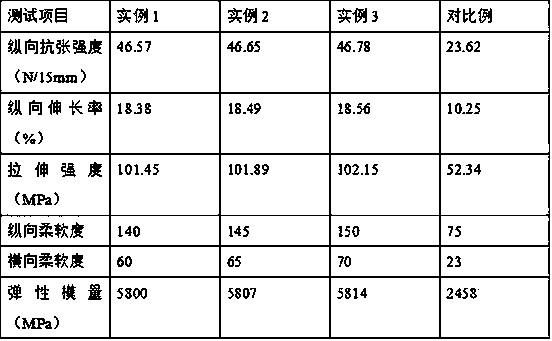

Examples

example 1

[0025] In parts by weight, 13 parts of polyvinylidene fluoride, 2 parts of cellulose acetate, 50 parts of dimethylacetamide, 5 parts of polyvinylpyrrolidone, and 4 parts of lithium chloride are placed in a water bath, and the stirrer is started at 400r Start stirring at a speed of 1 / min, heat up to 60°C, stir and mix for 12 hours, then cool down to 40°C and let stand for defoaming for 12 hours to obtain a casting solution; put 6g of sodium alginate powder into a dropping funnel and stir In the three-necked flask of the device, start the stirrer, start stirring at a speed of 300r / min, put 40mL of sodium periodate solution with a mass fraction of 10% into the dropping funnel, and pour it into the three-necked flask at a dropping rate of 4mL / min. Add sodium alginate solution dropwise to the solution, after the dropwise addition, protect the three-necked flask from light, react at room temperature for 20 hours, and obtain the oxidation product solution; add 4mL ethylene glycol to t...

example 2

[0027] In parts by weight, 14 parts of polyvinylidene fluoride, 4 parts of cellulose acetate, 55 parts of dimethylacetamide, 5 parts of polyvinylpyrrolidone, and 4 parts of lithium chloride are placed in a water bath, and the stirrer is started at 450r Start stirring at a speed of 1 / min, heat up to 65°C, stir and mix for 13.5 hours, then cool down to 45°C and stand for defoaming for 13 hours to obtain a casting solution; put 8g of sodium alginate powder into a dropping funnel and In the three-necked flask of the agitator, start the agitator, start stirring at a speed of 320r / min, put 50mL of sodium periodate solution with a mass fraction of 10% into the dropping funnel, and pour it into the three-necked flask at a rate of 5mL / min. Add sodium alginate solution dropwise into the flask. After the dropwise addition, protect the three-necked flask from light and react at room temperature for 22 hours to obtain an oxidation product; add 4 mL of ethylene glycol to the above oxidation ...

example 3

[0029] In parts by weight, 15 parts of polyvinylidene fluoride, 5 parts of cellulose acetate, 60 parts of dimethylacetamide, 6 parts of polyvinylpyrrolidone, and 5 parts of lithium chloride are placed in a water bath, and the stirrer is started at 500r Start stirring at a speed of 1 / min, heat up to 70°C, stir and mix for 15 hours, then cool down to 50°C and let stand for defoaming for 14 hours to obtain a casting solution; put 10g of sodium alginate powder into a dropping funnel and stir In the three-necked flask of the device, start the stirrer, start stirring at a speed of 500r / min, put 60mL of sodium periodate solution with a mass fraction of 10% into the dropping funnel, and pour it into the three-necked flask at a dropping rate of 6mL / min. Sodium alginate solution was added dropwise to the solution, after the dropwise addition, the three-necked flask was protected from light, and reacted at room temperature for 24 hours to obtain an oxidation product solution; 5 mL of ethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com