SiC ceramic structural part and preparation method thereof

A technology for structural parts and ceramics, applied in the field of SiC ceramic structural parts and their preparation, can solve the problems of low density, high internal porosity and low bending strength of structural parts, so as to improve dimensional accuracy, improve mechanical properties, and reduce porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention discloses a SiC ceramic structural part and a preparation method thereof, comprising the following steps:

[0032] S1. Construct the three-dimensional model of the structural part, and then convert the three-dimensional model into an STL format file;

[0033] S2. Slicing the STL format file through magics software to obtain the layer thickness and number of layers, and export it as an SLC file, and import the SLC format file into a 3D printer; the thickness of each layer is 0.05-0.2mm;

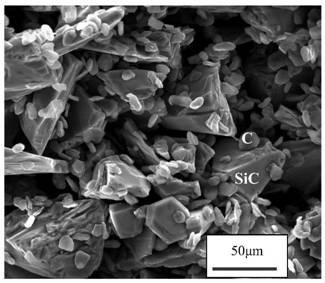

[0034] S3, mix SiC powder, C powder and binder powder, the mass percentage of SiC powder in the mixed powder is: 60%~90%, the mass percentage of C powder is: 5%~30%, the mass percentage of binder powder is 5%-30%; the binder includes epoxy resin or phenolic resin; the particle size of SiC powder is 10-200 μm, the particle size of C powder is 1-25 μm, and the particle size of adhesive powder is 1-10 μm; the mixed The powder is added into the mixer and mixed evenly to obtai...

Embodiment 1

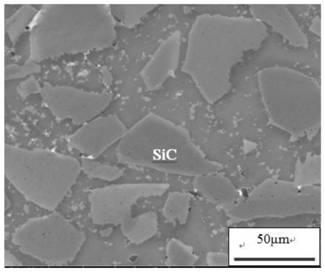

[0045] Construct the structural part model and convert it into an STL format file, perform layered slice thickness and layer number on the STL format file, the layer thickness is 0.1mm, and export it as an SLC file and import it into the 3D printer; mix SiC powder, C powder and Epoxy resin powder, the SiC powder mass percentage content in the mixed powder is 60%, the C powder mass percentage content is 20%, the epoxy resin powder percentage content is 20%, obtain the uniform mixed powder after mixing by mixer; Put the ceramic powder into the barrel of the 3D printer to start printing. The working temperature of the working box is 40°C, the laser power is 16W, and the scanning speed is 2000mm / s. After printing, place the ceramic body at room temperature for 10 minutes. The body is subjected to cold isostatic pressing after sheathing treatment, the isostatic pressure is 200MPa; then it is degreasing, the degreasing temperature is 800°C, and the degreasing time is 30min; ; Remove...

Embodiment 2

[0047] Construct the structural part model and convert it into an STL format file, perform layered slice thickness and layer number on the STL format file, the layer thickness is 0.05mm, and export it as an SLC file and import it into a 3D printer; mix SiC powder, C powder and Phenolic resin powder, the mass percentage of SiC powder in the mixed powder is 70%, the mass percentage of C powder is 20%, and the percentage content of phenolic resin powder is 10%. After mixing by a mixer, a uniform mixed powder is obtained; the ceramic Put the powder into the barrel of the 3D printer and start printing. The working temperature of the working box is 30°C, the laser power is 18W, and the scanning speed is 3000mm / s. After the sheathing treatment, cold isostatic pressing treatment is carried out, and the isostatic pressure is 220MPa; then degreasing treatment is carried out, the degreasing temperature is 900°C, and the degreasing time is 40min; The residual silicon on the surface is rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com