Multifunctional anisotropic fiber, and preparation method using adverse solvent solidification

A poor solvent, multi-functional technology, applied in the direction of fiber chemical characteristics, chemical instruments and methods, cellulose/protein conjugated artificial filaments, etc., can solve the problems of complicated separation steps, not green enough, limited applications, etc., to achieve preparation Simple process, good reproducibility, and wide range of potential applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] In order to solve the above technical problems, the technical solution adopted in the present invention is: provide a preparation method for preparing the multifunctional anisotropic fiber, the prepared fiber is realized by a microfluidic device, comprising the following steps:

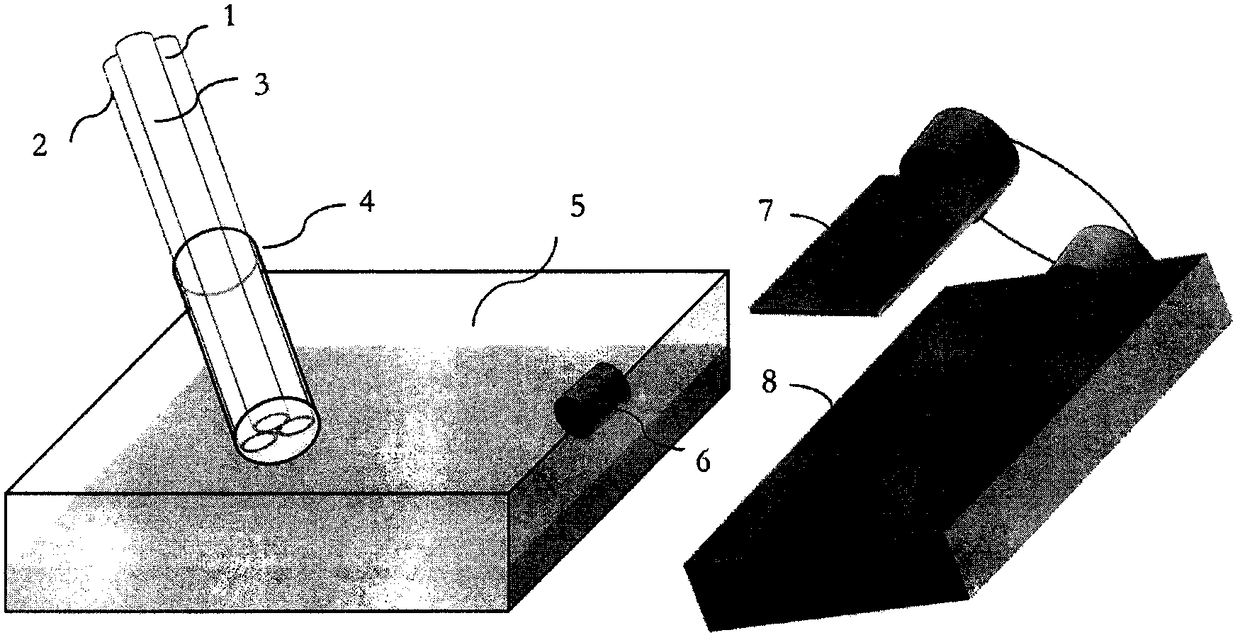

[0026] First, the construction of the microfluidic device

[0027] Utilizing microfluidic processing technology, using microchannels to construct microfluidic devices with different channel numbers and different shell structures at channel outlets, and equipped with transition small pulleys and fiber collectors:

[0028] Next, the preparation steps of multifunctional fiber:

[0029] Use the pump body to fill one or more polymers into the syringes respectively, connect the respective microchannel inlets, use the digital control syringe pump to control the flow rate of the polymer solution in each microchannel, and insert the end of the microfluidic device into the receiving chamber of the water....

Embodiment 1

[0041] Embodiment 1 has the preparation of the anisotropic multifunctional fiber of two-component structure:

[0042] 1. Construction of the microfluidic device:

[0043] The microfluidic channel is prepared by means of micro-machine and manual processing, including each single-channel part and a shell structure part at the outlet of the channel, and the shell structure part is a circular structure.

[0044] 2. Fiber Preparation

[0045] (1) Configuration of various polymer solutions:

[0046] Polymer solution 1: 10% polyacrylonitrile solution, adding 0.2 nanometer ferric oxide particles.

[0047] Polymer solution 2: 11% cellulose acetate solution, wrapped in 1% coumarin as the model drug

[0048] (2) Formation and curing of fibers

[0049] Put the above two solutions into different syringes, connect the respective microchannel inlets, immerse the outlet of the microfluidic device below the liquid level of distilled water, use a numerically controlled syringe pump to control...

Embodiment 2 3

[0050] Example 2 Preparation of three-sided anisotropic multifunctional fiber

[0051] 1. Construction of the microfluidic device:

[0052] A microfluidic channel is prepared by using micro-machine and manual processing methods, including each single-channel component, and a shell structure component at the channel outlet (the shell-like structure is circular).

[0053] 2. Fiber Preparation

[0054] (1) Configuration of various polymer solutions:

[0055] Polymer solution 1: 25% cellulose acetate phthalate solution was prepared, and 1% coumarin was wrapped as a model drug.

[0056] Polymer solution 2: Prepare 30% polystyrene solution, wrap 1% Ag nanoparticles and 1% coumarin as model drugs.

[0057] Polymer solution 3: prepare 20% polycaprolactone solution, and wrap 0.5% iron ferric oxide nanoparticles.

[0058] (2) Formation and curing of fibers

[0059] Put the above three solutions into different syringes, connect the respective microchannel inlets, immerse the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com