ZnMgO thin film and preparation method thereof

A thin film and compound technology, applied in the field of ZnMgO thin film and its preparation, can solve the problems of unfavorable ultraviolet detection devices, flat absorption cut-off edge, etc., and achieve the effects of steep absorption cut-off edge, simple preparation process and low growth temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The present invention also provides a method for preparing the above-mentioned ZnMgO thin film, comprising: using an organic zinc compound as a zinc source, an organic magnesium compound as a magnesium source, and growing ZnMgO on a substrate in a metal organic compound chemical vapor deposition device fed with oxygen film.

[0027] Among them, the present invention has no special limitation on the sources of all raw materials, which can be commercially available.

[0028] The organozinc compound is an organozinc compound well known to those skilled in the art, and there is no special limitation. In the present invention, it is preferably a dialkylzinc, more preferably a dialkylzinc with an alkyl carbon number of 1 to 5. Zinc, more preferably diethylzinc and / or dimethylzinc; The organomagnesium compound is an organomagnesium compound well-known to those skilled in the art, and there is no special limitation. In the present invention, it is preferably diethylmagnesium an...

Embodiment 1

[0038] 1.1 Use trichlorethylene, acetone, and ethanol to clean the sapphire substrate respectively, and then dry it with dry nitrogen.

[0039] 1.2 Put the sapphire substrate in step 1.1 into the MOCVD growth equipment, adjust the growth temperature to 550°C, and the vacuum degree of the growth chamber to 2×10 4 Pa, using diethylzinc as the zinc source, dimethylmagnesium as the magnesium source, the molar concentration ratio of zinc and magnesium is adjusted by using different high-purity nitrogen carrier gas ratios, and the oxygen flow rate is 550mL / min. The carrier gas flow rate of the zinc-based pipeline is 16mL / min, and the carrier gas flow rate of the dimethylmagnesium pipeline is 50mL / min.

[0040] 1.3 After growing for 2 hours, turn off the organic source, lower the temperature at a rate of 5°C / min, and finally lower it to room temperature, take out the substrate, and obtain a ZnMgO film with a molar ratio of Zn to Mg in the film of 3:7.

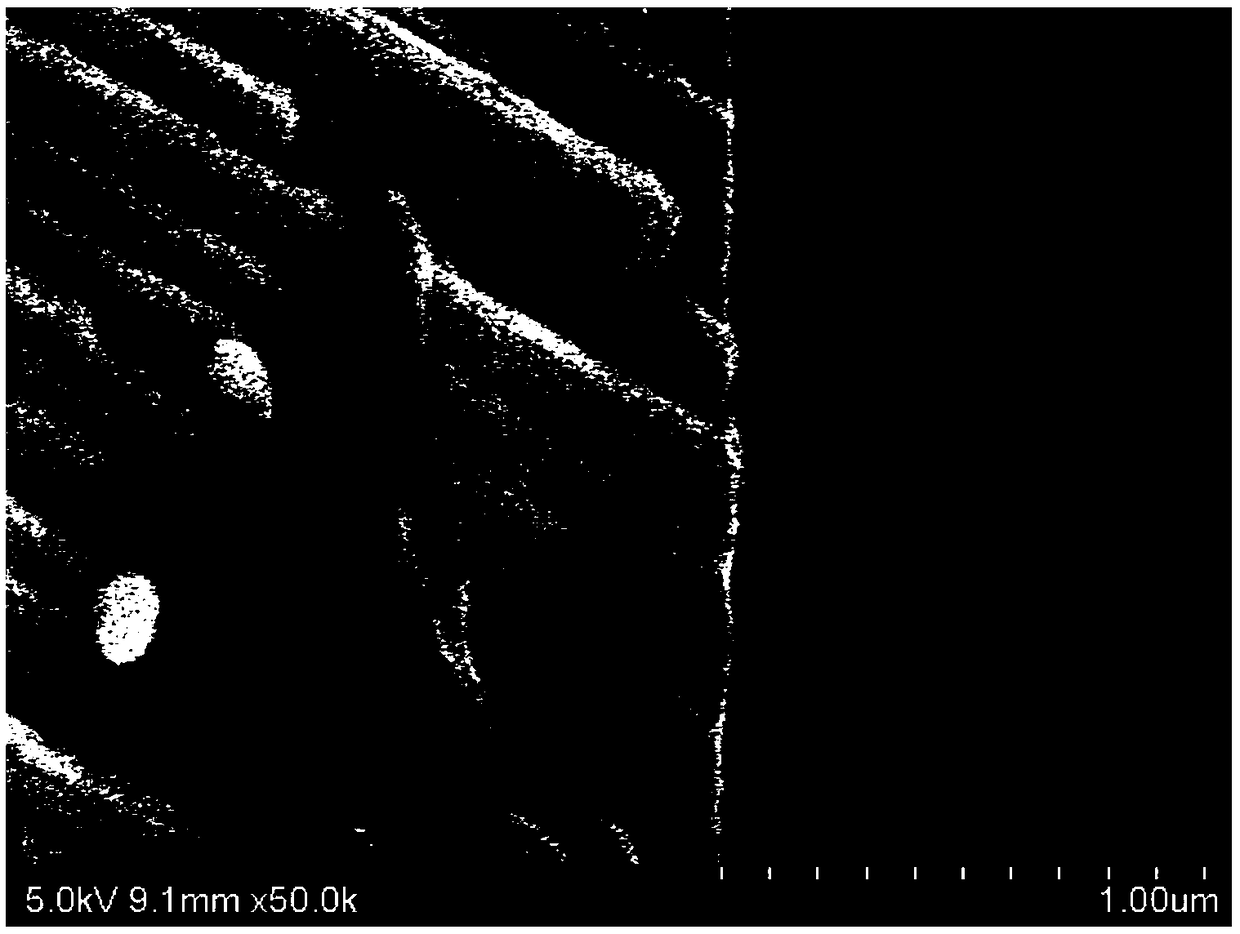

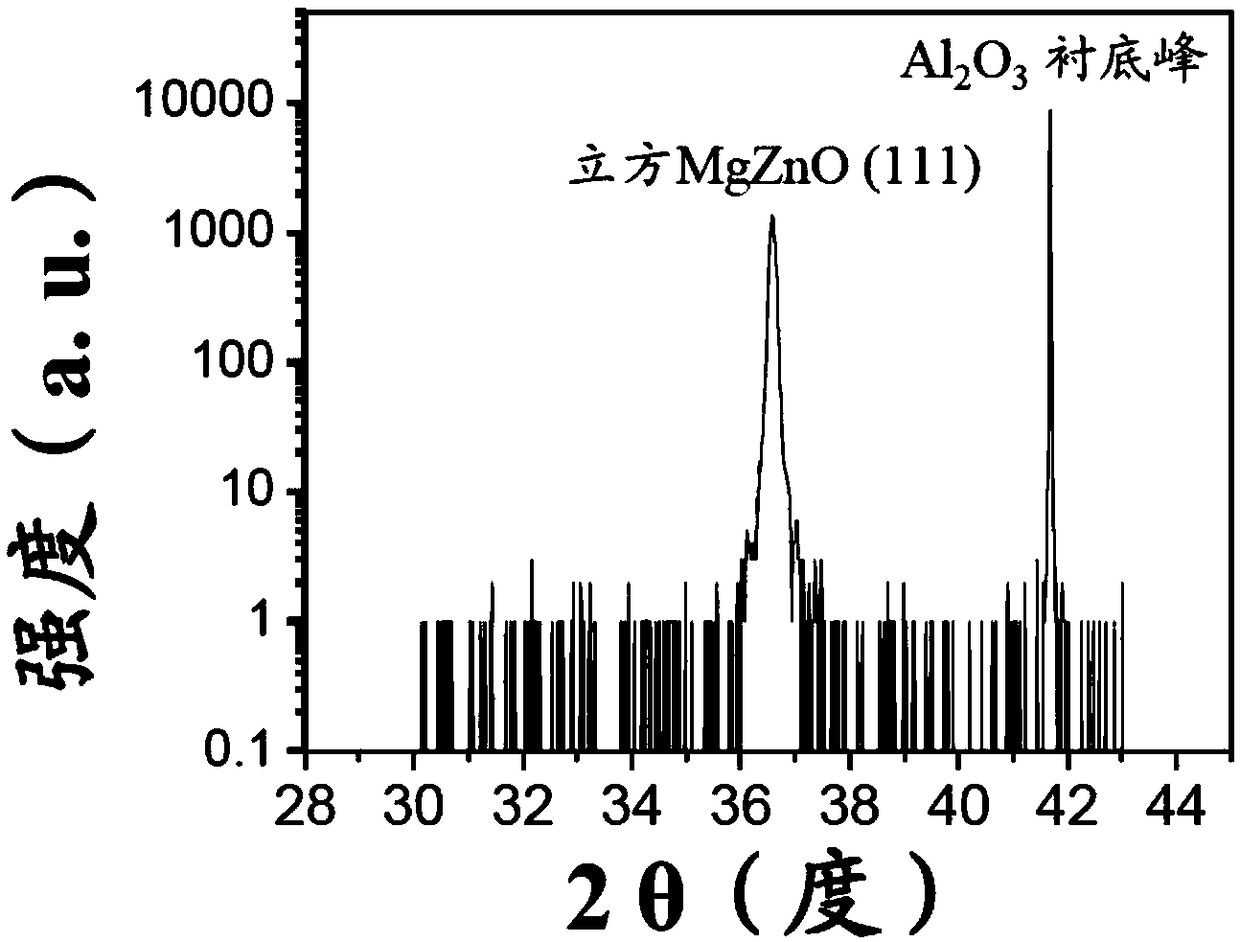

[0041] Utilize scanning elect...

Embodiment 2

[0045] 2.1 Use trichlorethylene, acetone, and ethanol to clean the sapphire substrate respectively, and then dry it with dry nitrogen.

[0046] 2.2 Put the sapphire substrate in step 2.1 into the MOCVD growth equipment, adjust the growth temperature to 550°C, and the vacuum degree of the growth chamber to 2×10 4 Pa, using diethylzinc as the zinc source, dimethylmagnesium as the magnesium source, the molar concentration ratio of zinc and magnesium is adjusted by using different high-purity nitrogen carrier gas ratios, and the oxygen flow rate is 550mL / min. The carrier gas flow rate of the zinc-based pipeline was 16mL / min, and the carrier gas flow rate of the dimethylmagnesium pipeline was 80mL / min.

[0047] 2.3 After growing for 2 hours, turn off the organic source, lower the temperature at a rate of 5°C / min, and finally lower it to room temperature, take out the substrate, and obtain a ZnMgO film. The molar ratio of Zn to Mg in the film is 1.8:8.2.

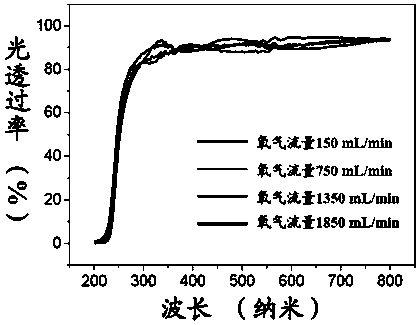

[0048] The ultraviolet-vi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com