Preparation method of lithium-ion battery, negative pole piece and element-doped carbon nanotube

A carbon nanotube and element doping technology, which is applied in battery electrodes, non-aqueous electrolyte battery electrodes, nanotechnology, etc., can solve the problems of poor hydrophilicity of carbon nanotubes, complicated preparation process, and reduced production capacity, so as to improve long cycle Performance, simple processing technology, and the effect of improving energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing element-doped carbon nanotubes. The elements include one or more of sulfur, boron and nitrogen.

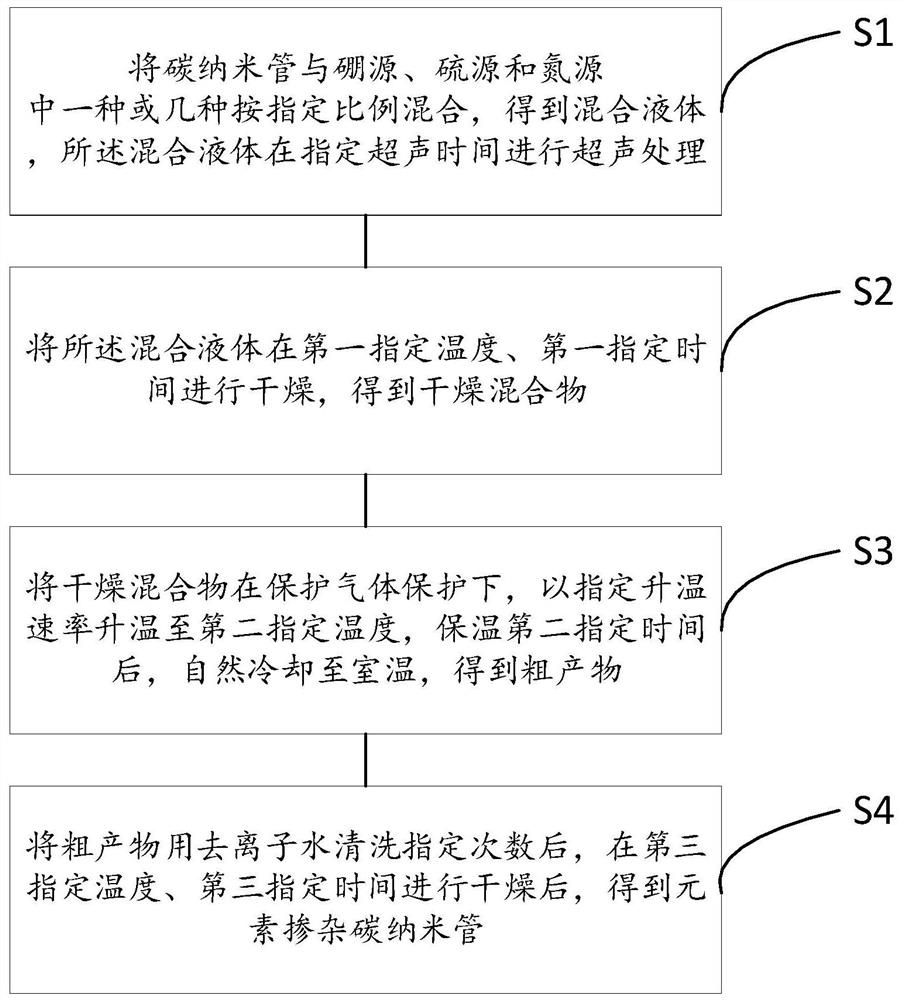

[0024] refer to figure 1 , a method for preparing an element-doped carbon nanotube conductive agent according to an embodiment of the present invention, comprising:

[0025] S1: After mixing carbon nanotubes with one or more of boron source, sulfur source and nitrogen source in a specified ratio, perform ultrasonic treatment at a specified ultrasonic time to obtain a mixed liquid.

[0026] In this embodiment, the boron source includes boric acid; the sulfur source includes one or more of magnesium sulfate and thiourea, preferably magnesium sulfate; the nitrogen source includes one or more of nitric acid, ammonium chloride, ammonium sulfate and ammonium nitrate, Nitric acid is preferred; the specified ratio includes a mass ratio of 1: (0.5-10); the specified ultrasonic time includes 1-5h.

[0027] In this embodiment, boron, nit...

Embodiment 1

[0044]50g of carbon nanotubes and 1000g of nitric acid solution (nitric acid concentration 50%) were mixed, and after ultrasonication for 1h, a mixed liquid was obtained; the mixed liquid was dried at a temperature of 80°C for 24h to obtain a dry mixture; the dry mixture was heated in a tube furnace Under the protection of argon, the temperature was raised to 600 °C at a heating rate of 2 °C / min, and then naturally cooled to room temperature after heat preservation for 4 hours to obtain the crude product; the crude product was washed with deionized water for 5 times and dried at 80 °C for 24 hours to obtain nitrogen element Doped carbon nanotubes; directly add nitrogen-doped carbon nanotube powder into graphite for stirring, wherein graphite: nitrogen-doped carbon nanotubes: binder = 95.9:0.1:4, the solid content of the slurry after stirring 55% and a viscosity of 4000cP, coated with a transfer coater to obtain a negative electrode sheet; the negative electrode sheet is divided...

Embodiment 2

[0046] 50g of carbon nanotubes and 500g of boric acid solution (boric acid concentration 70%) were mixed, and after ultrasonication for 3h, a mixed liquid was obtained; the mixed liquid was dried at a temperature of 90°C for 18h to obtain a dry mixture; the dry mixture was heated in a tube furnace Under the protection of a mixed gas of nitrogen and ammonia, the temperature was raised to 800°C at a heating rate of 4°C / min, and after holding for 2 hours, the crude product was naturally cooled to room temperature to obtain the crude product; after the crude product was washed with deionized water for 6 times, it was heated at 90°C Dry for 18 hours to obtain boron-doped carbon nanotubes; directly add boron-doped carbon nanotube powder into the simple silicon material for stirring, wherein nano-silicon: boron-doped carbon nanotubes: binder = 95.92: 0.08 : 4. After stirring, the solid content of the slurry is 57%, and the viscosity is 3800cP. It is coated with a transfer coater, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com