Nitrogen-doped carbon microspheres/Pd composite catalyst, preparation method and application thereof

A composite catalyst, nitrogen-doped carbon technology, applied in fuel cell type half cells and primary cell type half cells, electrical components, battery electrodes, etc. Complex process and other problems, to achieve the effect of improving catalytic activity, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

[0038] The preparation of embodiment 1 No. 1 catalyst

[0039] 1) Disperse 80mg of acidified Vulcan Carbon uniformly in 20mL of ultrapure water by ultrasonic to obtain carbon microsphere suspension;

[0040] 2) Add 2.6g of ammonium sulfate, 1.2g of ammonium persulfate, and 11mg of palladium nitrate into 60mL of ultrapure water, and stir electromagnetically to obtain a mixed solution;

[0041] 3) After uniformly mixing the carbon microsphere suspension and the mixed solution, transfer it to a 100mL hydrothermal kettle with a polytetrafluoroethylene liner, put it in an oven with a temperature of 140°C for 12 hours, and cool to At room temperature, the product was washed and dried to obtain a composite catalyst of palladium and carbon microspheres (referred to as No. 1 catalyst).

Embodiment 2

[0042] Preparation of No. 2 catalyst of embodiment 2

[0043] 1) Heat the acidified Vulcan Carbon in 30% NH3 / Ar atmosphere at a rate of 5°C / min to 300°C for 2h, with a gas flow rate of 200mL / min.

[0044] 2) Uniformly disperse 80 mg of Vulcan Carbon after heat treatment with ammonia gas into 20 mL of ultrapure water to obtain carbon microsphere suspension;

[0045] 3) Add 2.6g of ammonium sulfate, 1.2g of ammonium persulfate, and 11mg of palladium nitrate into 60mL of ultrapure water, and stir electromagnetically to obtain a mixed solution;

[0046] 4) After uniformly mixing the carbon microsphere suspension and the mixed solution, transfer it to a 100mL hydrothermal kettle with a polytetrafluoroethylene liner, put it in an oven with a temperature of 140°C for 12 hours, and cool to At room temperature, the product was washed and dried to obtain a composite catalyst of palladium and carbon microspheres (referred to as No. 2 catalyst).

Embodiment 3

[0047] Preparation of No. 3 catalyst of embodiment 3

[0048] 1) Heat the acidified Vulcan Carbon in 30% NH3 / Ar atmosphere at a rate of 5°C / min to 600°C for 2h, with a gas flow rate of 200mL / min.

[0049] 2) Uniformly disperse 80 mg of Vulcan Carbon after heat treatment with ammonia gas into 20 mL of ultrapure water to obtain carbon microsphere suspension;

[0050] 3) Add 2.6g of ammonium sulfate, 1.2g of ammonium persulfate, and 11mg of palladium nitrate into 60mL of ultrapure water, and stir electromagnetically to obtain a mixed solution;

[0051] 4) After uniformly mixing the carbon microsphere suspension and the mixed solution, transfer it to a 100mL hydrothermal kettle with a polytetrafluoroethylene liner, put it in an oven with a temperature of 140°C for 12 hours, and cool to At room temperature, the product was washed and dried to obtain a composite catalyst of palladium and carbon microspheres (referred to as No. 3 catalyst).

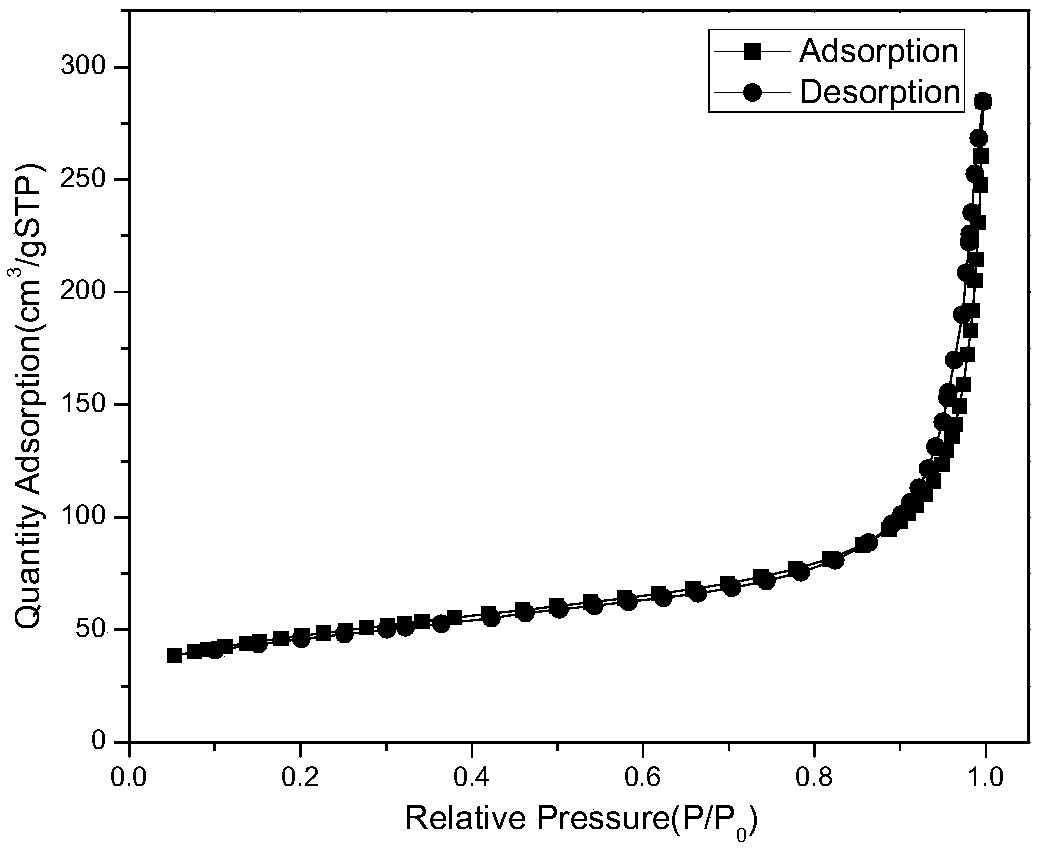

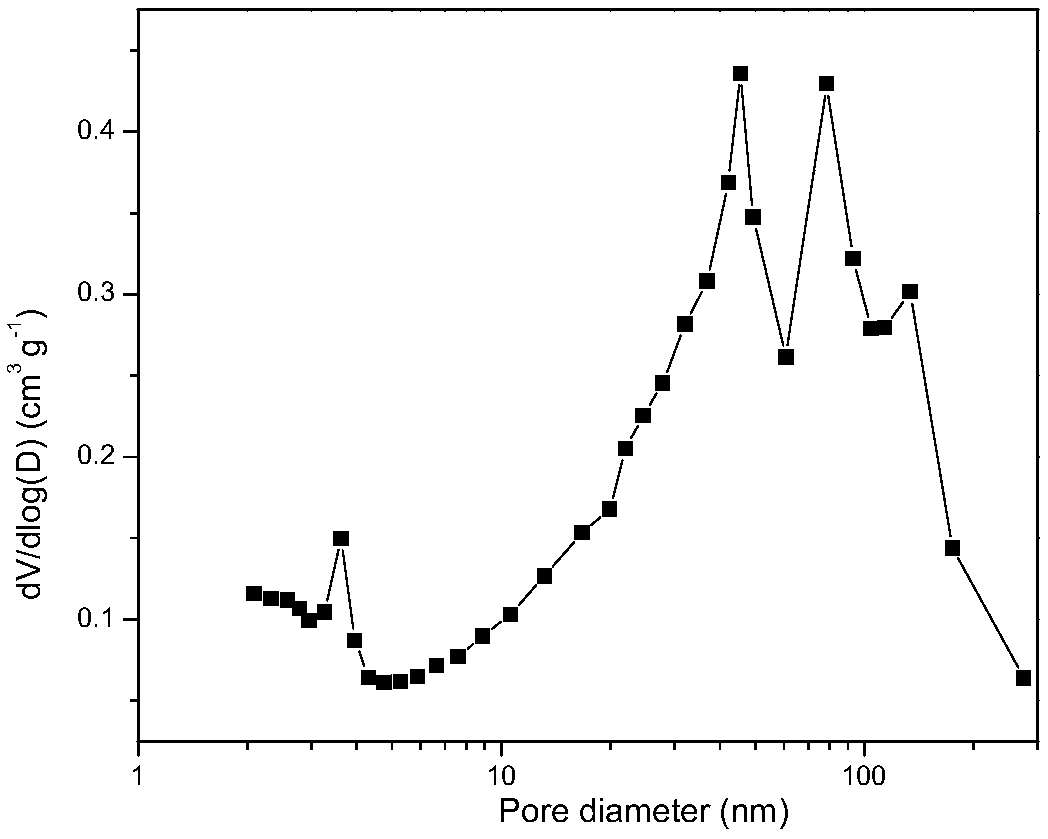

[0052] figure 1 Transmission electron mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com