Method and device for preparing spherical titanium alloy fine powder based on special centrifugal atomizing disc

A centrifugal atomization disc and centrifugal atomization technology are applied in the field of spherical titanium alloy fine powder and devices based on special centrifugal atomization discs. The effect of increasing the strength and improving the toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

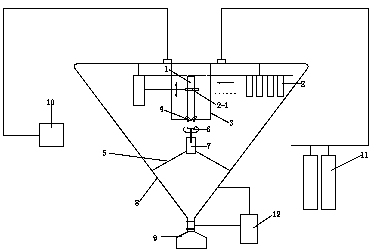

Method used

Image

Examples

Embodiment 1

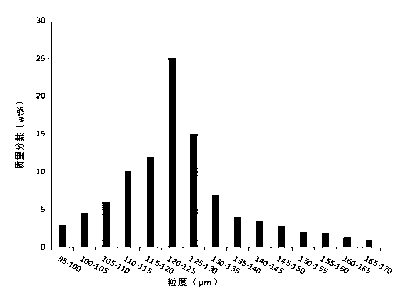

[0027] Take the titanium alloy rod and machine it into a raw material rod with a length of 1000mm and a diameter of Ф100mm. Feed the raw material rods into the melting chamber with a feeding device. When the raw material rod enters the melting chamber, turn on the vacuum device until the internal vacuum drops to 10 -2 Below MPa, stop vacuuming at this time, open the inert gas manifold, use argon as the inert gas to fill the equipment, and keep the gas pressure at 1 MPa. Turn on all toroidal induction coils, refrigeration equipment, and centrifugal atomizing disk power supplies. The material of the centrifugal atomization disc is titanium boride. The shape of the centrifugal atomization disc is a dish-shaped smooth disc with a diameter of Ф160mm, the vertical height difference between the edge and the center of the disc is 5mm, and the rotation speed is 12000rpm. The temperature in the centrifugal atomization chamber is below 80°C, and the temperature in the collection device ...

Embodiment 2

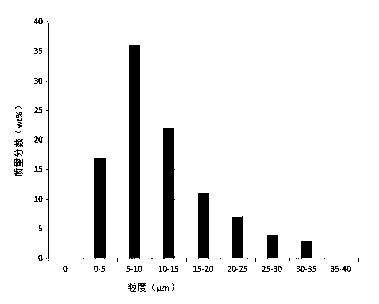

[0029] Take the titanium alloy rod and process it into a raw material rod with a length of 300mm and a diameter of Ф30mm on a lathe. Feed the raw material rods into the melting chamber with a feeding device. When the raw material rod enters the melting chamber, turn on the vacuum device until the internal vacuum drops to 10 -2 Below MPa, stop vacuuming at this time, open the inert gas busbar, fill the equipment with argon as the inert gas, and keep the gas pressure at 1 MPa. Turn on the power of the toroidal induction coil, refrigeration equipment and centrifugal atomization disk. The material of the centrifugal atomization disk is titanium boride, the shape is bowl-shaped, the diameter is Ф20mm, the vertical height difference between the edge of the disk and the center is 8mm, and the rotation speed is 160000rpm. The temperature in the centrifugal atomization chamber is below 80°C, and the temperature in the collection device is maintained at about 40°C. After the equipment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com