High-efficiency papermaking wastewater treatment agent and preparation method thereof

A paper-making wastewater and treatment agent technology, which is applied in the direction of processing wastewater treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of poor treatment effect, unstable performance, low cost, etc., and achieve treatment Increased effect, improved compatibility, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

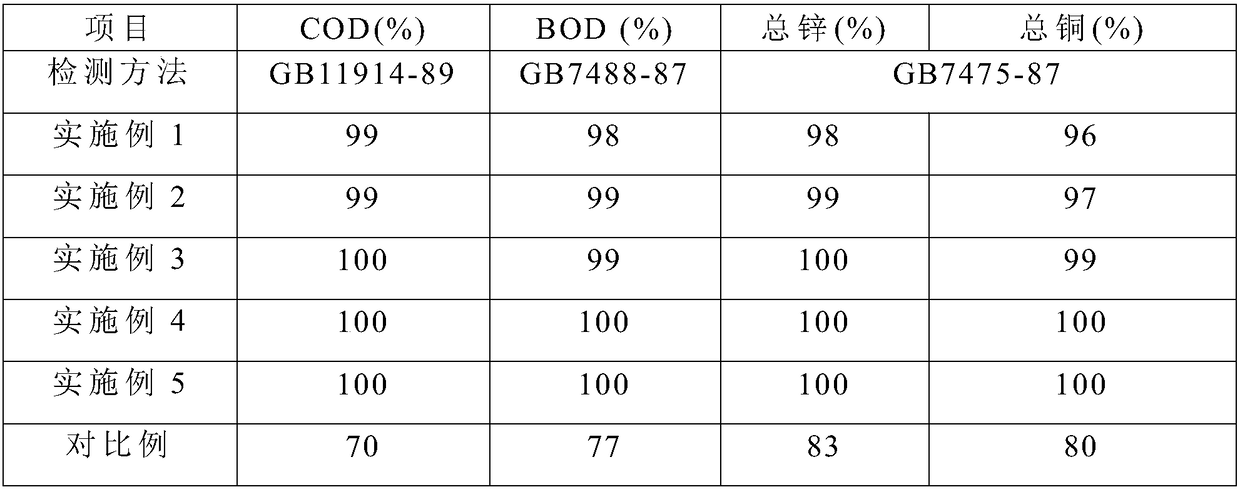

Examples

Embodiment 1

[0031] A high-efficiency treatment agent for papermaking wastewater, which is made of the following components in parts by weight: 10 parts of phthaloamidoferrocene polyphenylene ether, 10 parts of mesoporous Ti-Al-O, and 30 parts of modified polyetheramine; Phthalamidoferrocene polyphenylene ether is prepared from 1,1'-dibromoferrocene, 4-hydroxyphenylboronic acid and 4,5-dichlorophthalamide through chemical reaction.

[0032] The preparation method of described phthaloamidoferrocene polyphenylene ether, comprises the steps:

[0033] ⅠAdd 22.6g of 1,1'-dibromoferrocene and 10g of 4-hydroxyphenylboronic acid to 100g of tetrahydrofuran, then add 100g of aqueous solution of sodium carbonate with a mass fraction of 5%, [1,1'-bis (Diphenylphosphine) ferrocene] Palladium dichloride dichloromethane complex 1.5g, stirred and reacted for 18 hours at 75° C. in a nitrogen atmosphere, the crude product was extracted 3 times with chloroform, and the organic layer was deionized water and ...

Embodiment 2

[0039] A high-efficiency treatment agent for papermaking wastewater, which is made of the following components in parts by weight: 13 parts of phthaloamidoferrocene polyphenylene ether, 11 parts of mesoporous Ti-Al-O, and 32 parts of modified polyetheramine; Phthalamidoferrocene polyphenylene ether is prepared from 1,1'-dibromoferrocene, 4-hydroxyphenylboronic acid and 4,5-dichlorophthalamide through chemical reaction.

[0040] The preparation method of described phthaloamidoferrocene polyphenylene ether, comprises the steps:

[0041] ⅠAdd 22.6g of 1,1'-dibromoferrocene and 10g of 4-hydroxyphenylboronic acid to 110g of toluene, then add 100g of potassium carbonate aqueous solution with a mass fraction of 6%, [1,1'-bis (Diphenylphosphine)ferrocene]Palladium dichloride dichloromethane complex 1.5g, stirred and reacted for 19 hours under a helium atmosphere at 77°C, the crude product was extracted 4 times with chloroform, and the organic layer was deionized Wash twice with water...

Embodiment 3

[0047] A high-efficiency treatment agent for papermaking wastewater, which is made of the following components in parts by weight: 15 parts of phthaloamidoferrocene polyphenylene ether, 13 parts of mesoporous Ti-Al-O, and 35 parts of modified polyetheramine; Phthalamidoferrocene polyphenylene ether is prepared from 1,1'-dibromoferrocene, 4-hydroxyphenylboronic acid and 4,5-dichlorophthalamide through chemical reaction.

[0048] The preparation method of described phthaloamidoferrocene polyphenylene ether, comprises the steps:

[0049] ⅠAdd 22.6g of 1,1'-dibromoferrocene and 10g of 4-hydroxyphenylboronic acid to 135g of xylene, then add 100g of sodium carbonate aqueous solution with a mass fraction of 7%, [1,1'- Bis(diphenylphosphine)ferrocene]palladium dichloride dichloromethane complex 1.5g, stirred and reacted for 20 hours at 80°C in a neon atmosphere, the crude product was extracted 5 times with chloroform, and the organic layer was used Ionized water and saturated saline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com