Naphthalene structure-containing high heat-resistant hyperbranched polyimide as well as preparation method and application thereof

A technology of polyimide and polyimide film, applied in the field of material science, can solve the problems of limited wide application, large inter-chain distance, decreased heat resistance, etc., to achieve good application prospects, improve thermal properties, free volume increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

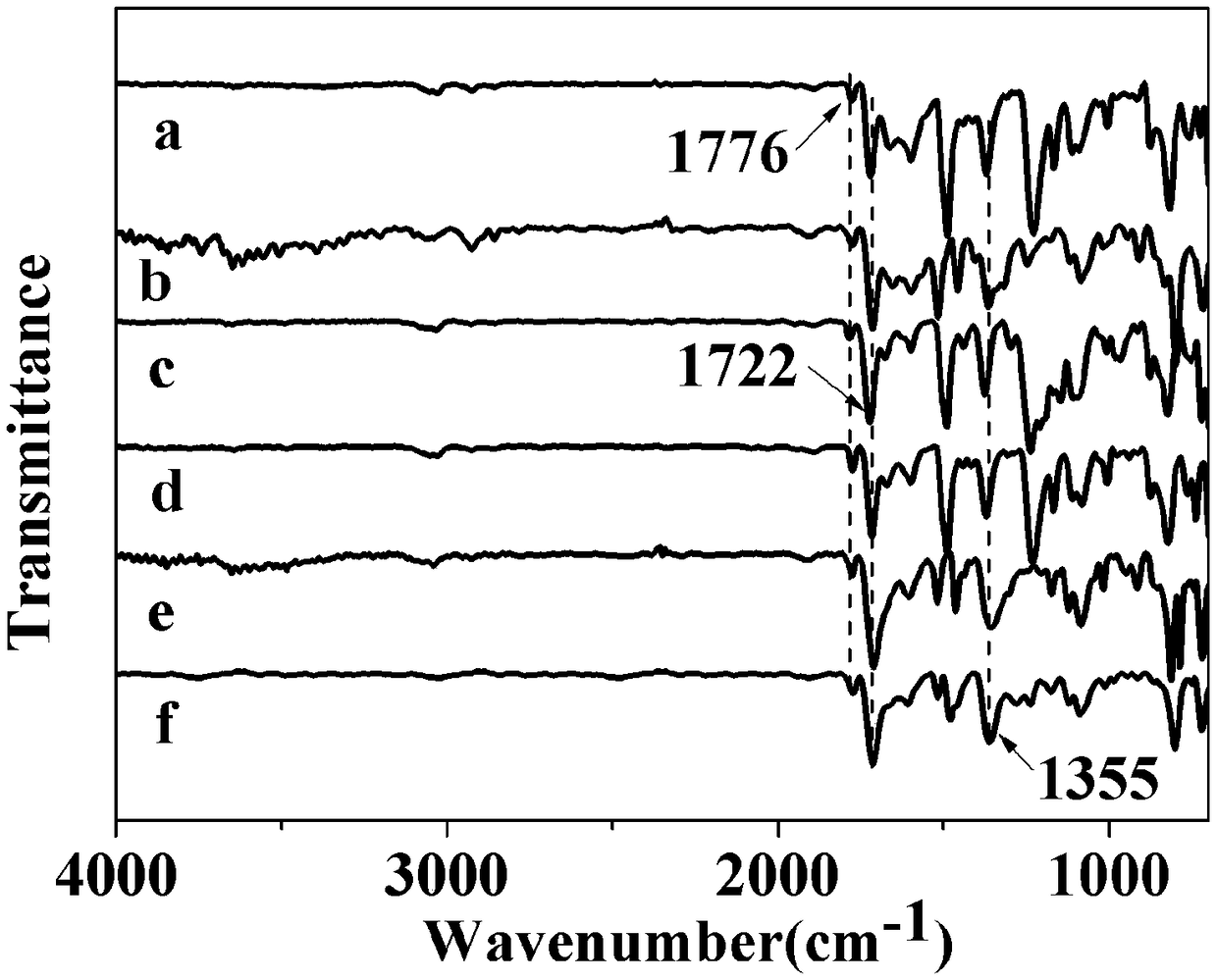

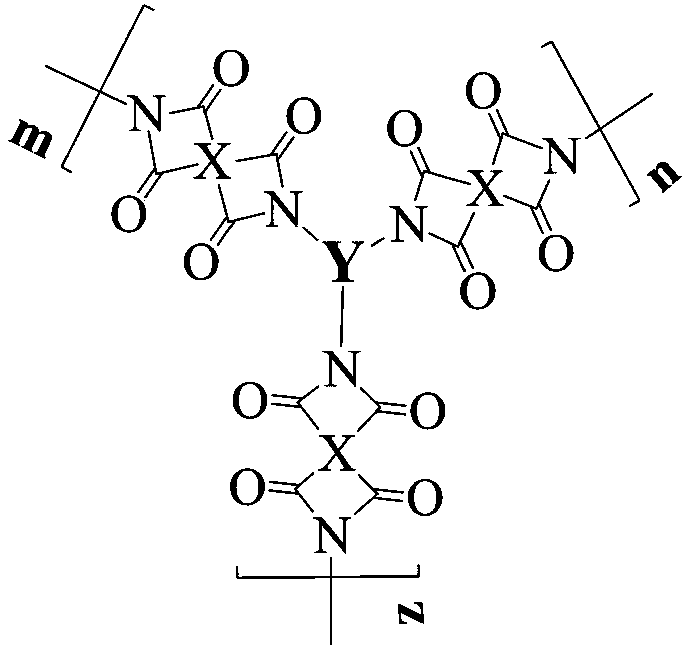

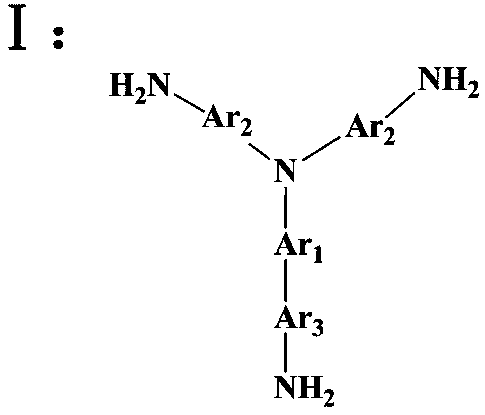

[0037] Add 0.4362g (2mmol) of pyromellitic dianhydride (PMDA) and 36ml of N,N-dimethylformamide into a three-necked flask, blow in argon, raise the temperature to 30°C, and add the triamine monomer N 1 -(4-aminophenyl)-N 1 -(3-(4-aminophenyl)naphthalen-1-yl)benzene-1,4-diamine 0.4165g (1mmol) dissolved in 40ml N,N-dimethylformamide with a constant pressure dropping funnel in 1 ~ 2h Add it dropwise into a three-necked flask, then continue to react for 15 hours, then add 6ml of acetic anhydride and 2ml of triethylamine, heat up to 45°C and continue to react for 12 hours, after the reaction is completed, cool to room temperature and discharge in methanol, filter, wash, repeat 2-3 Finally, place it in a vacuum drying oven at 80°C for 24 hours to obtain a brown hyperbranched polyimide polymer, whose structural formula is as follows:

[0038]

Embodiment 2

[0040] Add 0.4515g (2.07mmol) of pyromellitic dianhydride (PMDA) and 15ml of N,N-dimethylacetamide into a three-necked flask, blow in argon, raise the temperature to 30°C, and add the triamine monomer N 1 -(4-aminophenyl)-N 1 -(8-(4-aminophenyl)naphthalen-1-yl)benzene-1,4-diamine 0.4165g (1mmol) dissolved in 16ml of N,N-dimethylacetamide with a constant pressure dropping funnel in 1 ~ 2h Add it dropwise into a three-necked flask, then continue to react for 18 hours, then add 6.2ml of acetic anhydride and 2.1ml of triethylamine, heat up to 45°C and continue to react for 16 hours, after the reaction is completed, cool to room temperature and discharge in ethanol, filter, wash, repeat 2 ~3 times, and finally placed in a vacuum drying oven at 80°C for 24 hours to obtain a tan hyperbranched polyimide polymer, whose structural formula is as follows:

[0041]

Embodiment 3

[0043]Add 0.4413g (1.5mmol) of 3,3',4,4'--biphenyltetracarboxylic dianhydride (BPDA) and 10ml of N-methylpyrrolidone into a three-necked flask, pass in argon, raise the temperature to 30°C, and Triamine Monomer N 2 -(6'-amino-[2,2'-binaphthalen]-7-yl)-N 2 -(5-aminothiophen-2-yl)thiophene-2,5-diamine 0.4786g (1mmol) dissolved in 8ml of N-methylpyrrolidone was evenly added dropwise into the three-necked flask with a constant pressure dropping funnel for 1-2 hours, and then continued the reaction 12h, then add 12ml acetic anhydride and 3ml triethylamine, raise the temperature to 45°C and continue the reaction for 22h, after the reaction is completed, cool to room temperature and discharge the material in ethanol, filter, wash, repeat 2-3 times, and finally place it at 80°C for vacuum drying Dry 24h in the box, obtain the hyperbranched polyimide polymer of tan, and its structural formula is as follows:

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com