A kind of zinc corrosion inhibitor in hydrochloric acid medium and its preparation method and application

A technology of corrosion inhibitor and medium, applied in the field of zinc corrosion inhibitor and its preparation, can solve the problems of low zinc potential and accelerate the corrosion effect of zinc film, and achieve the effects of short time, easy discharge and production cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A zinc corrosion inhibitor in hydrochloric acid medium, the corrosion inhibitor is prepared from the following raw materials in parts by weight: 2.0g phthalocyanine, 3.0g chitosan, 0.5g methylpyrrolidone, 0.8g thiourea, 1.5g ten Hexaalkylammonium bromide, 1.0g cinnamaldehyde, 2.0g hydroxypropyl cross-linked starch, 1.0g butynediol, mixed solvent (DMF30g, glacial acetic acid 25g, acetone 20g, ethanol 13.2g), fully stirred, heated to 50~80℃, completely dissolve the solute in the solvent, and set aside.

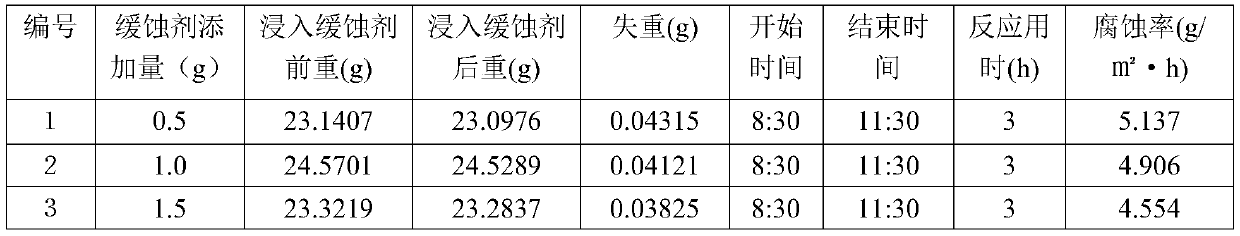

[0037] Adopt the corrosion inhibition rate and the corrosion rate of this corrosion inhibitor prepared by weight loss test to zinc, the steps are as follows:

[0038] Prepare 6 parts of the same hydrochloric acid with a mass percentage of 6% each 100ml, and carry out numbering 1, 2, 3, 4, 5, 6; then add the buffer prepared above from No. 1 to No. Etchant 0.5g, 1.0g, 1.5g, 2.0g, 2.5g and 3.0g, stir and mix well;

[0039] Take 6 pieces of zinc test pieces with a specifica...

Embodiment 2

[0047] A zinc corrosion inhibitor in hydrochloric acid medium, the corrosion inhibitor is prepared from the following raw materials in parts by weight: 2.0g cobalt phthalocyanine, 3.0g chitosan, 0.5g methylpyrrolidone, 1.0g thiourea, 1.8g Cetyl ammonium bromide, 1.2g cinnamaldehyde, 2.0g sodium carboxymethylcellulose, 1.0g butynediol, mixed solvent (DMF 30g, glacial acetic acid 25g, acetone 20g, ethanol 6g, butyl acetate 6.5g ), fully stirred, heated to 50-80°C to completely dissolve the solute in the solvent, and set aside.

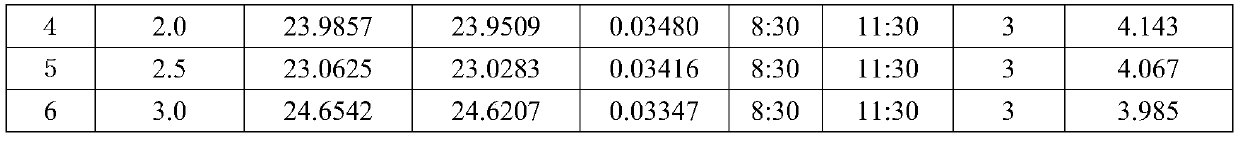

[0048] Adopt the corrosion inhibition rate and the corrosion rate of this corrosion inhibitor prepared by weight loss test to zinc, the steps are as follows:

[0049] Prepare 6 parts of the same hydrochloric acid with a mass percentage of 6% each 100ml, and carry out numbering 1, 2, 3, 4, 5, 6; then add the buffer prepared above from No. 1 to No. Etchant 0.5g, 1.0g, 1.5g, 2.0g, 2.5g and 3.0g, stir and mix well;

[0050] Take 6 pieces of zinc test piece...

Embodiment 3

[0057] A zinc corrosion inhibitor in hydrochloric acid medium, the corrosion inhibitor is prepared from the following raw materials in parts by weight: 2.0g zinc phthalocyanine, 3.0g chitosan, 1.0g methylpyrrolidone, 0.8g thiourea, 1.5g Cetyl ammonium bromide, 1.5g cinnamaldehyde, 2.0g sodium carboxymethylcellulose, 1.5g butynediol, mixed solvent (DMF 30g, glacial acetic acid 25g, acetone 20g, ethanol 5g, glycerin 6.7g ), fully stirred, heated to 50-80°C to completely dissolve the solute in the solvent, and set aside.

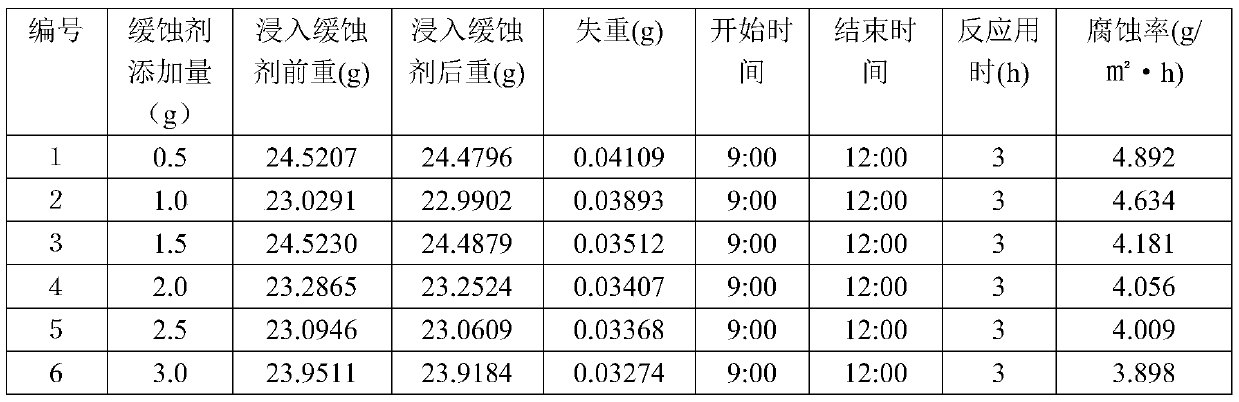

[0058] Adopt the corrosion inhibition rate and the corrosion rate of this corrosion inhibitor prepared by weight loss test to zinc, the steps are as follows:

[0059] Prepare 6 parts of the same hydrochloric acid with a mass percentage of 6% each 100ml, and carry out numbering 1, 2, 3, 4, 5, 6; then add the buffer prepared above from No. 1 to No. Etchant 0.5g, 1.0g, 1.5g, 2.0g, 2.5g and 3.0g, stir and mix well;

[0060] Take 6 pieces of zinc test pieces with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com