Method for recovering nitrogen, phosphorus and fluorine based on electrochemical reactor

A recovery method and reactor technology, applied in the direction of electrolysis components, electrolysis process, etc., can solve the problems of complex nitrogen, phosphorus and fluorine recovery process, and achieve the effects of shortening the settling time, small footprint of the device, and improving the removal rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

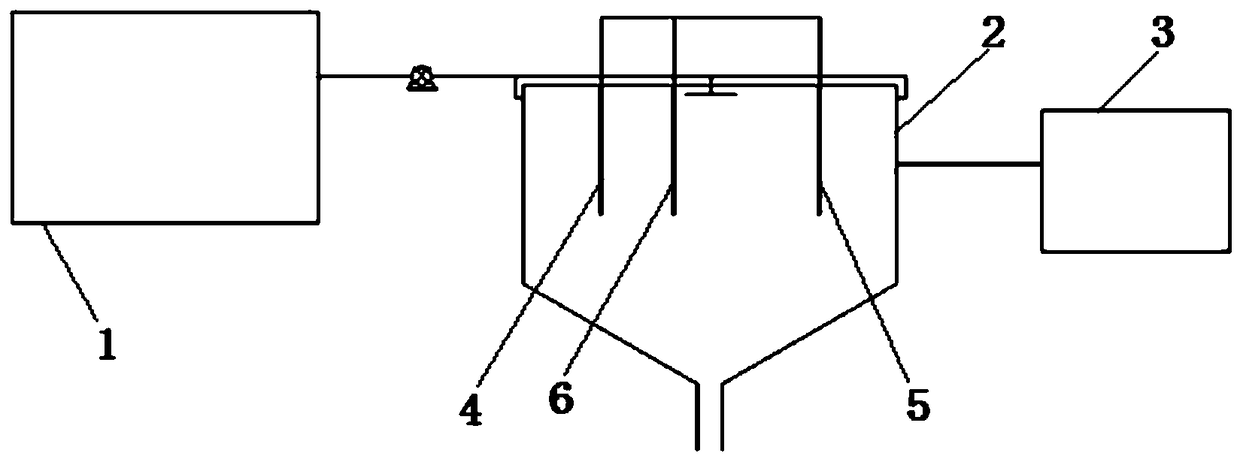

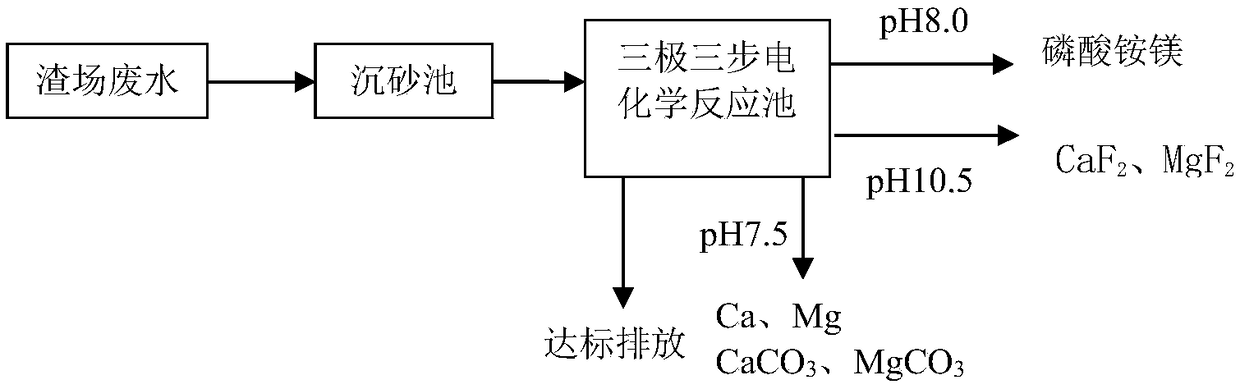

[0023] The present invention is a method for recovering nitrogen, phosphorus and fluorine based on an electrochemical reactor, which uses figure 1 The device shown includes a grit chamber 1; an electrochemical reaction tank 2; a water storage tank 3; a calcium-magnesium alloy rod 4; a graphite rod 5 and a stainless steel plate 6. In this method, firstly, the waste water from the slag field flows into the grit chamber 1, and is precipitated and separated to remove larger massive impurities and floating objects in the waste water, and then the waste water flows through the electrochemical reaction tank 2, and calcium is put into the electrochemical reaction tank respectively. Magnesium alloy rod 4, graphite rod 5, and stainless steel plate 6. Under the action of direct current, the electrochemical reaction cell is divided into three steps, followed by the first two steps to put the calcium-magnesium alloy rod 4 and the graphite rod 5, and the third step to put the graphite rod 5...

Embodiment 2

[0045] The seepage discharge of a phosphogypsum slag field is 1200m 3 / d, wherein the phosphorus content in the wastewater is 2500mg / L, the fluorine content is 1200mg / L, the ammonia nitrogen content is 400mg / L, and the pH is 4. Wastewater from the slag field flows into the grit chamber 1, and is precipitated and separated to remove larger massive impurities and floating objects in the waste water, and is lifted into the electrochemical reaction tank 2 by a lift pump. Under the action of direct current, calcium-magnesium alloy rods 4, graphite rods 5 and stainless steel plates 6 are sequentially put into the electrochemical reaction cell. In the first step, the calcium-magnesium alloy rod 4 is placed as the anode, and the graphite rod 5 is used as the cathode, and electron transfer occurs to provide Mg 2+ and OH - , pH gradually increased to 8.5, Mg 2+ Phosphorus, nitrogen and other substances in the waste water are precipitated and removed in the form of fertilizers such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com