Method for determining trace elements in graphite by microwave digestion-ICP-OES (inductively coupled plasma-optical emission spectrometer)

A technology of -ICP-OES, medium and trace elements, which is applied in the field of microwave digestion-ICP-OES for the determination of trace elements in graphite, can solve the problems of complete immersion of trace elements in graphite samples, deviation of test results, etc., and achieve excellent high-temperature storage performance and speed Fast, fast and complete effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

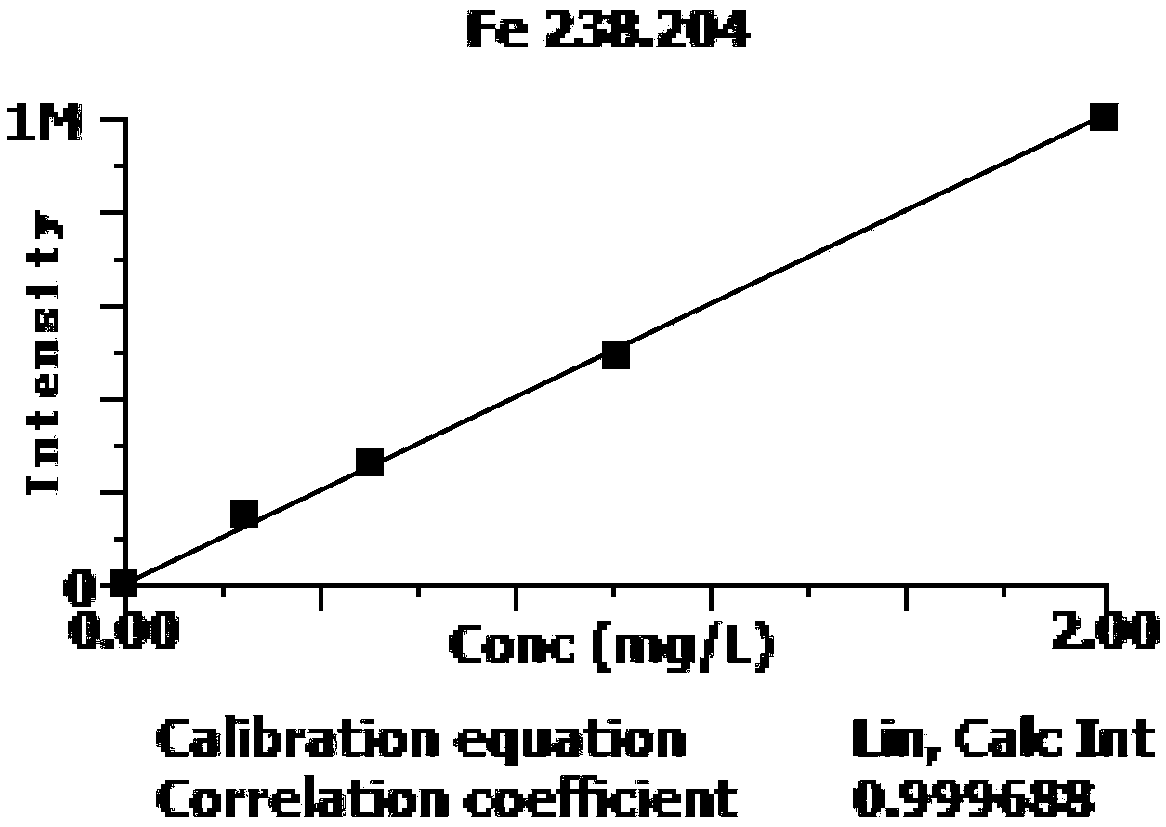

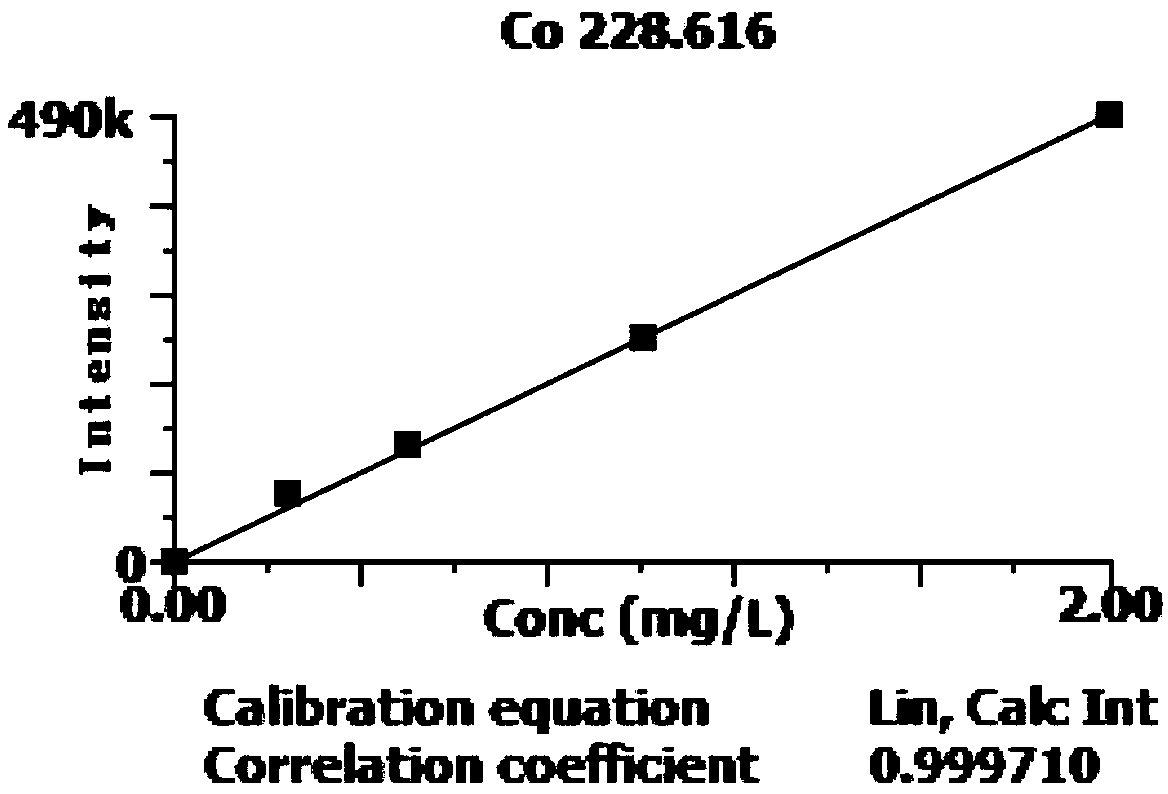

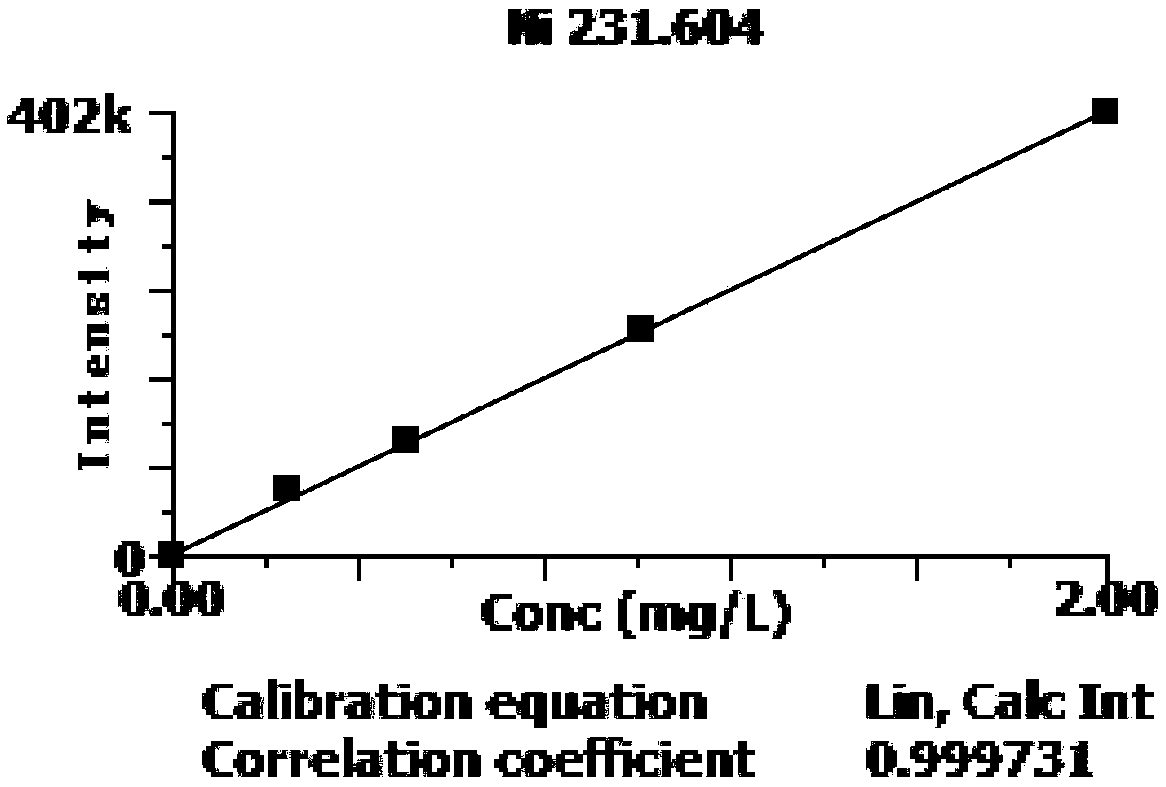

[0040] Use an electronic balance to weigh 0.3008g of graphite and add it to the digestion tank, then add 6mL of aqua regia to the digestion tank, tighten the closed digestion tank and place it in a microwave digestion instrument for digestion; after the digestion is completed and cooled to room temperature, heat the digestion tank acid, then transfer the digestion solution in the digestion tank to a 50mL plastic volumetric flask, rinse the digestion tank with water for 3 times, transfer the rinsing solution to the 50mL plastic volumetric flask, and then shake to a constant volume with water to obtain the Solution; set the analysis conditions of the inductively coupled plasma emission spectrometer, measure the solution to be measured with the inductively coupled plasma emission spectrometer, input the mass of the graphite sample and the volume of the solution to be measured, and directly measure iron, cobalt, nickel, copper, aluminum, and chromium and zinc content, as shown in T...

Embodiment 2

[0043] Use an electronic balance to weigh 0.4g of graphite and add it to the digestion tank, then add 9mL of aqua regia to the digestion tank, tighten the closed digestion tank and place it in a microwave digestion instrument for digestion; after the digestion is completed and cooled to room temperature, heat the digestion tank acid, then transfer the digestion solution in the digestion tank to a 50mL plastic volumetric flask, rinse the digestion tank with water for 3 times, transfer the rinsing solution to the 50mL plastic volumetric flask, and then shake to a constant volume with water to obtain the Solution; set the analysis conditions of the inductively coupled plasma emission spectrometer, measure the solution to be measured with the inductively coupled plasma emission spectrometer, input the mass of the graphite sample and the volume of the solution to be measured, and directly measure iron, cobalt, nickel, copper, aluminum, and chromium and zinc content, as shown in Tabl...

Embodiment 3

[0046] Use an electronic balance to weigh 0.5008g of graphite and add it to the digestion tank, then add 12mL of aqua regia to the digestion tank, tighten the closed digestion tank and place it in a microwave digestion instrument for digestion; after the digestion is completed and cooled to room temperature, heat the digestion tank acid, then transfer the digestion solution in the digestion tank to a 50mL plastic volumetric flask, rinse the digestion tank with water for 3 times, transfer the rinsing solution to the 50mL plastic volumetric flask, and then shake to a constant volume with water to obtain the Solution; set the analysis conditions of the inductively coupled plasma emission spectrometer, measure the solution to be measured with the inductively coupled plasma emission spectrometer, input the mass of the graphite sample and the volume of the solution to be measured, and directly measure iron, cobalt, nickel, copper, aluminum, and chromium and zinc content, as shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com