A preparation method of a high-performance lithium ion battery negative electrode material, namely a core-shell structure FeS2 <at> C nanoring

A lithium-ion battery, core-shell structure technology, applied in nanotechnology for materials and surface science, battery electrodes, nanotechnology, etc., can solve the problem of poor cycle and rate performance, not yet obtained nano-transition metal sulfide, conductivity Low-level problems, to achieve the effect of good rate performance, regular material structure, and simple formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

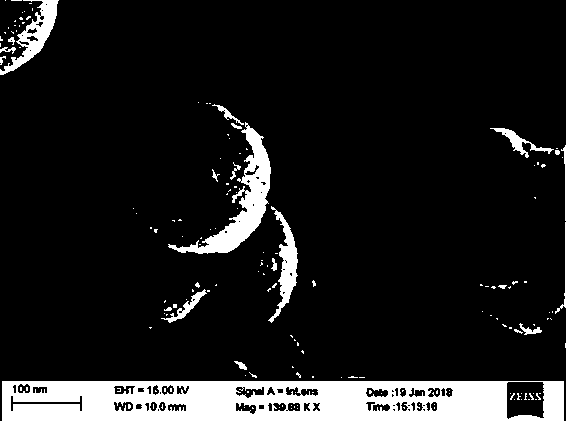

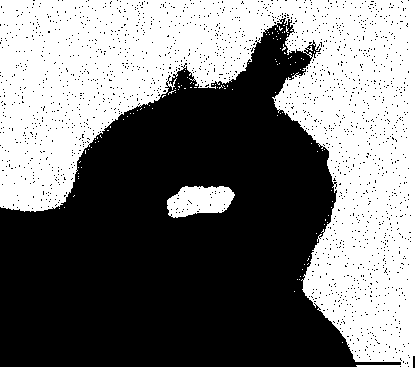

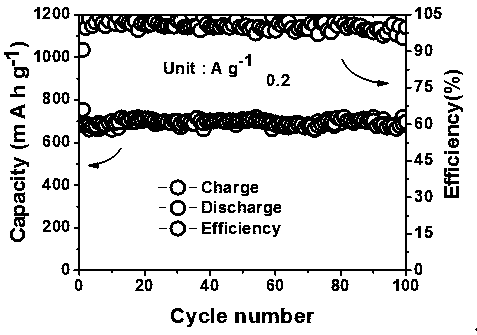

[0032] 5.4057gFeCl 3 ·6H 2 O, 0.0250gNaH 2 PO 4 2H 2 O and 0.0781gNa 2 SO 4 Dissolve in 1000ml of deionized water and stir for 1h at 100r / min. The solution was transferred into a Teflon-lined stainless steel autoclave and hydrothermally treated at 220 °C for 48 h. After the autoclave was cooled to room temperature, the sample was collected by centrifugation at a speed of 8000 r / min with a high-speed centrifuge, washed several times with deionized water and absolute ethanol, and finally dried in a constant temperature oven for 8 hours. The resulting red powder is Fe 2 o 3 nano ring. Then will contain 0.15g Fe 2 o 3 Granules, 0.5g cetyltrimethylammonium bromide and 15ml H 2 The aqueous dispersion of O was transferred to a round bottom flask. After stirring for 2 hours under 0.5h ultrasound and 100r / min speed, add 0.7g resorcinol, 56ml absolute ethanol and 0.2~0.4ml NH 4 Oh. Stir the flask at 35°C for 0.5 hours, and finally add 0.1~0.2ml of formalin solution (F). ...

Embodiment 2

[0036] 5.6gFeCl 3 ·6H 2 O, 0.020gNaH 2 PO 4 2H 2 O and 0.077gNa 2 SO 4 Dissolve in 1000ml of deionized water and stir for 1h at 100r / min. The solution was transferred into a Teflon-lined stainless steel autoclave and hydrothermally treated at 220 °C for 48 h. After the autoclave was cooled to room temperature, the sample was collected by centrifugation at a speed of 8000 r / min with a high-speed centrifuge, washed several times with deionized water and absolute ethanol, and finally dried in a constant temperature oven for 8 hours. The resulting red powder is Fe 2 o 3 nano ring.

[0037] Then will contain 0.2gFe 2 o 3 Granules, 2.64g cetyltrimethylammonium bromide and 40ml H 2 The aqueous dispersion of O was transferred to a round bottom flask. After stirring for 2 hours under 0.5h ultrasound and 100r / min speed, add 1.4g resorcinol, 200ml absolute ethanol and 0.8ml NH 4 Oh. Stir the flask at 35°C for 0.5 hours, and finally add 0.4~0.8ml of formalin solution (F). ...

Embodiment 3

[0040] 5.4~5.6gFeCl 3 ·6H 2 O, 0.023~0.026gNaH 2 PO 4 2H 2 O and 0.076~0.079gNa 2 SO 4 Dissolve in 1000ml of deionized water and stir for 1h at 100r / min. The solution was transferred into a Teflon-lined stainless steel autoclave and hydrothermally treated at 220 °C for 48 h. After the autoclave was cooled to room temperature, the sample was collected by centrifugation at a speed of 8000 r / min with a high-speed centrifuge, washed several times with deionized water and absolute ethanol, and finally dried in a constant temperature oven for 8 hours. The resulting red powder is Fe 2 o 3 nano ring. Then will contain 0.2g Fe 2 o 3 Granules, 0.2g cetyltrimethylammonium bromide and 20ml H 2 The aqueous dispersion of O was transferred to a round bottom flask. After stirring for 2 hours under 0.5h ultrasound and 100r / min speed, add 0.3g resorcinol, 55ml absolute ethanol and 0.15ml NH 4 Oh. The flask was stirred at 35 °C for 0.5 h and finally 0.15 ml of formalin solution (F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com