A lithium supplemental additive and its preparation method are provide

An additive and lithium-replenishing technology, applied in final product manufacturing, sustainable manufacturing/processing, electrolyte battery manufacturing, etc., can solve problems such as inability to achieve micro-nano level, inability to use it out of the box, corrosion and leakage, etc. The preparation method is simple and reliable, the initial discharge capacity is improved, and the consumption of lithium is compensated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

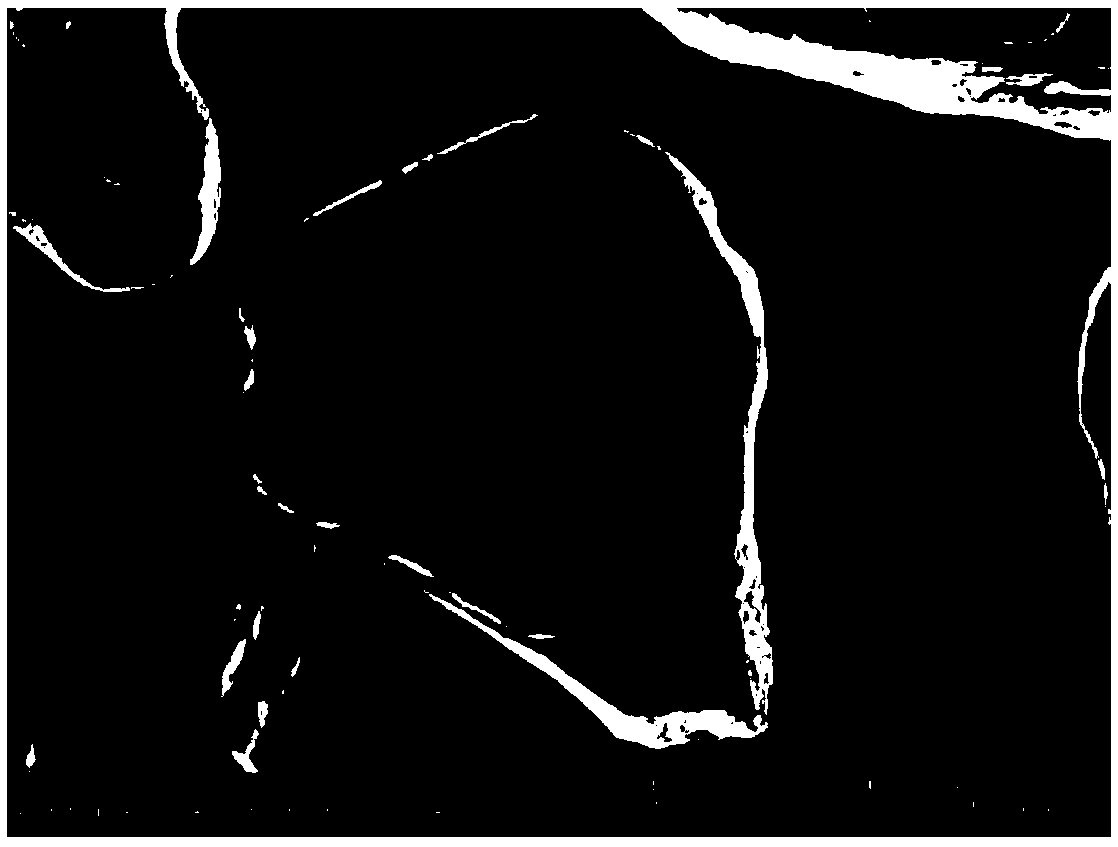

Image

Examples

Embodiment 1

[0037] According to CoMn(OH) 2 0.05Ti(OH) 4The molar ratio of metal elements in the chemical formula Cobalt sulfate, manganese sulfate, and titanium sulfate are prepared into a soluble metal mixed salt solution with a total concentration of metal ions of 1.5mol / l; at the same time, a sodium hydroxide solution with a concentration of 8mol / l and a concentration of 10mol / l of ammonia water; add ammonia water with a concentration of 10mol / l into the reactor as the bottom liquid of the reaction kettle, so that the concentration of ammonia water in the bottom liquid of the reaction kettle is controlled at 3.5g / l, and then the concentration is 8mol / l pumped through the peristaltic pump The sodium hydroxide solution is used to adjust the pH in the reaction kettle; the soluble metal mixed salt solution, sodium hydroxide solution, and ammonia water prepared by the peristaltic pump are added to the reaction kettle in parallel for stirring reaction; the temperature of the reaction kettle...

Embodiment 2

[0042] Select cobalt oxide with a D50 of 7 μm, lithium carbonate, and aluminum hydroxide, mix them uniformly according to the molar ratio of 1:6.06:0.4, and then sinter them at 1100°C for 9 hours in an air atmosphere; Iron, sieved to obtain the precursors of Li, Co, Al.

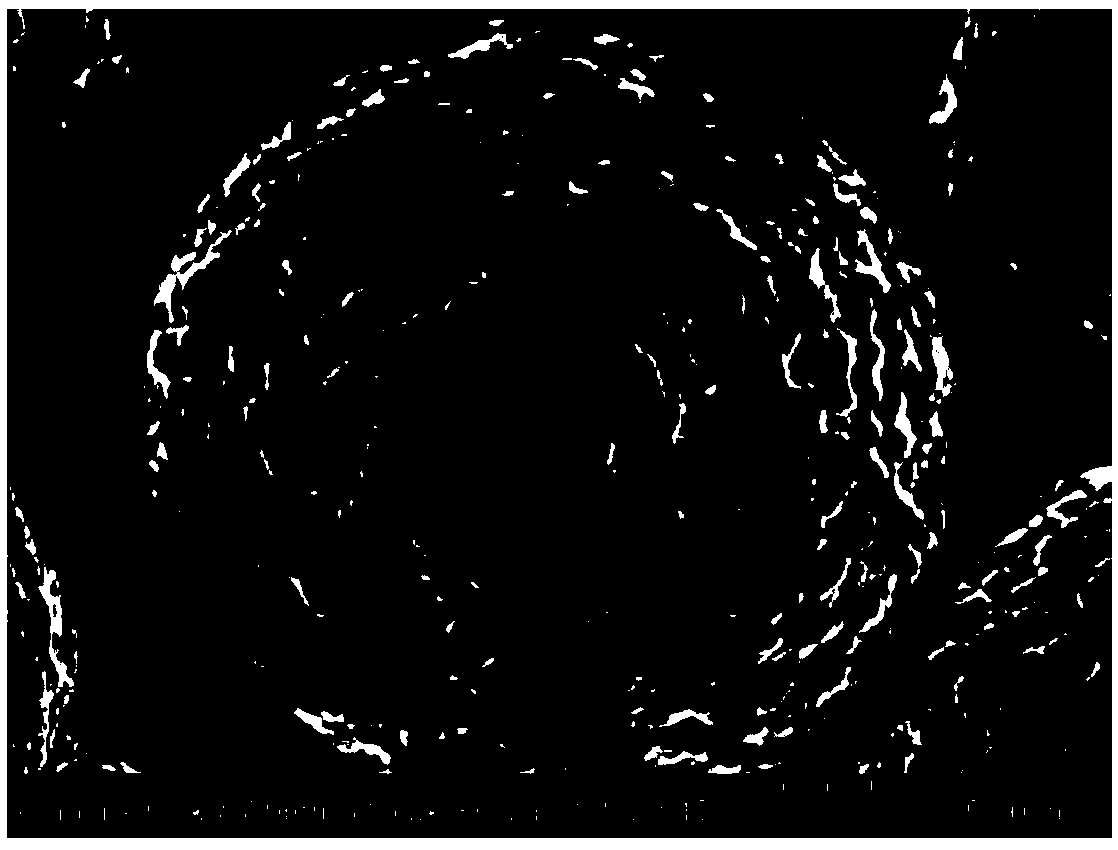

[0043] Precursors of Li, Co, Al in H 2 Ar-H with a volume content of 5% 2 Sintering at a temperature of 500°C for 6 hours under a mixed gas; after cooling, pass through dry air, and sintering at 80°C for 4 hours, after crushing and sieving, the final product is obtained. The appearance of the lithium-supplementing additive is as follows: figure 2 As shown, D50 is 7.1 μm, and the product 3Li is obtained 2 O 0.3Co 0.7CoO 0.2Al 2 o 3 The serial number is lithium supplement additive B.

Embodiment 3

[0045] Aluminum sulfate is dissolved in the cobalt sulfate solution, and it is configured into a mixed metal salt solution with cobalt ion and aluminum ion concentrations of 90g / L and 18g / L respectively. Inject a certain amount of pure water into the reaction kettle as the bottom liquid, add ammonium bicarbonate solution to adjust the pH value to 8.5, raise the temperature to 40°C, and mix the cobalt-aluminum mixed salt solution and the concentration of 230g / L bicarbonate at a stirring speed of 140rpm The ammonium solution is added to the reaction kettle at the same time to cause precipitation reaction. During the feeding process, the pH value of the reaction solution is controlled at about 8.0 until the material grows to 8 μm. After the feeding is completed, the stirring is stopped. The space continues to add material, so that the crystal continues to grow to 7 μm. The slurry is dehydrated, washed, dried, crushed and sieved to obtain a precursor powder containing Co and Al. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com