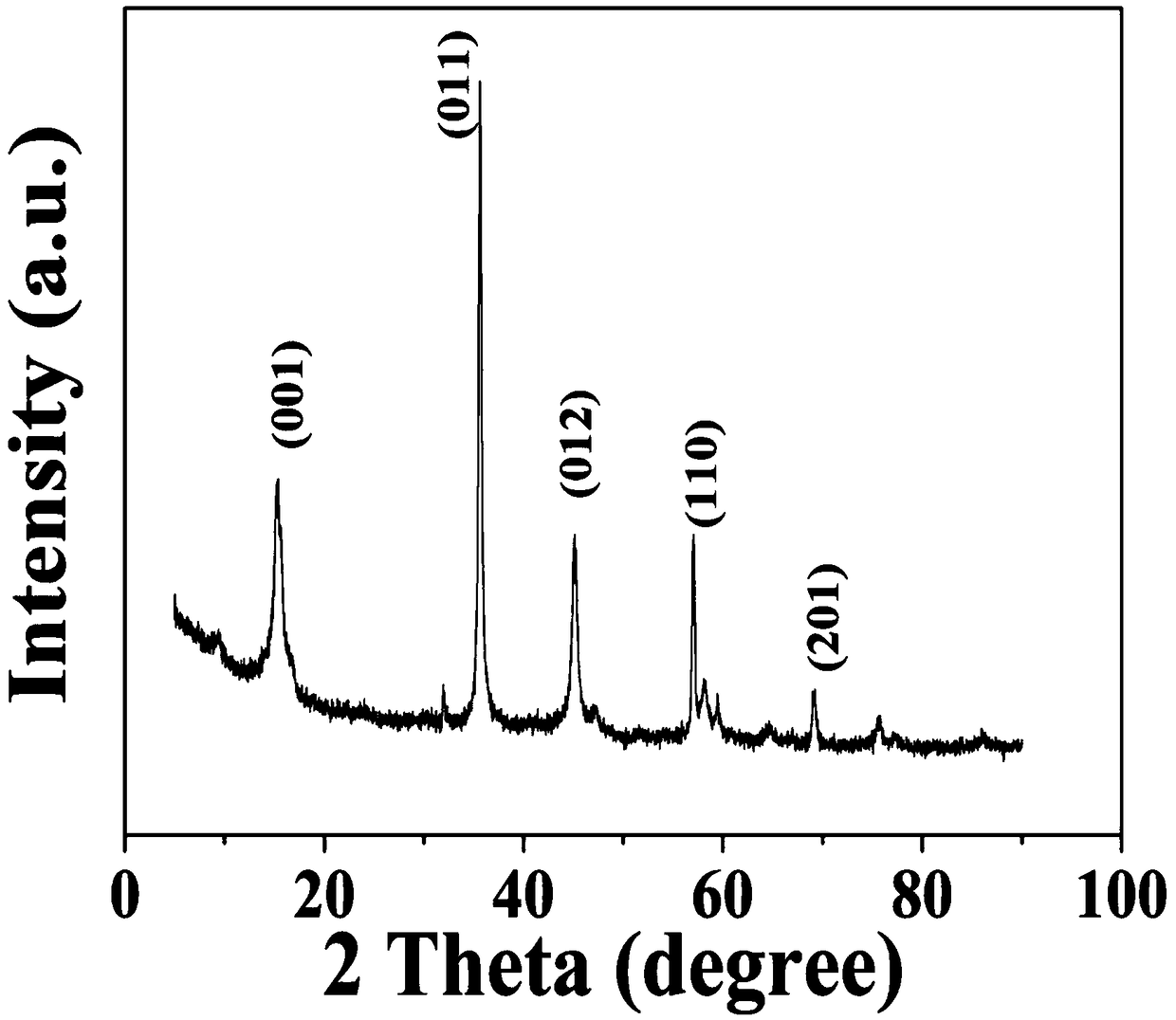

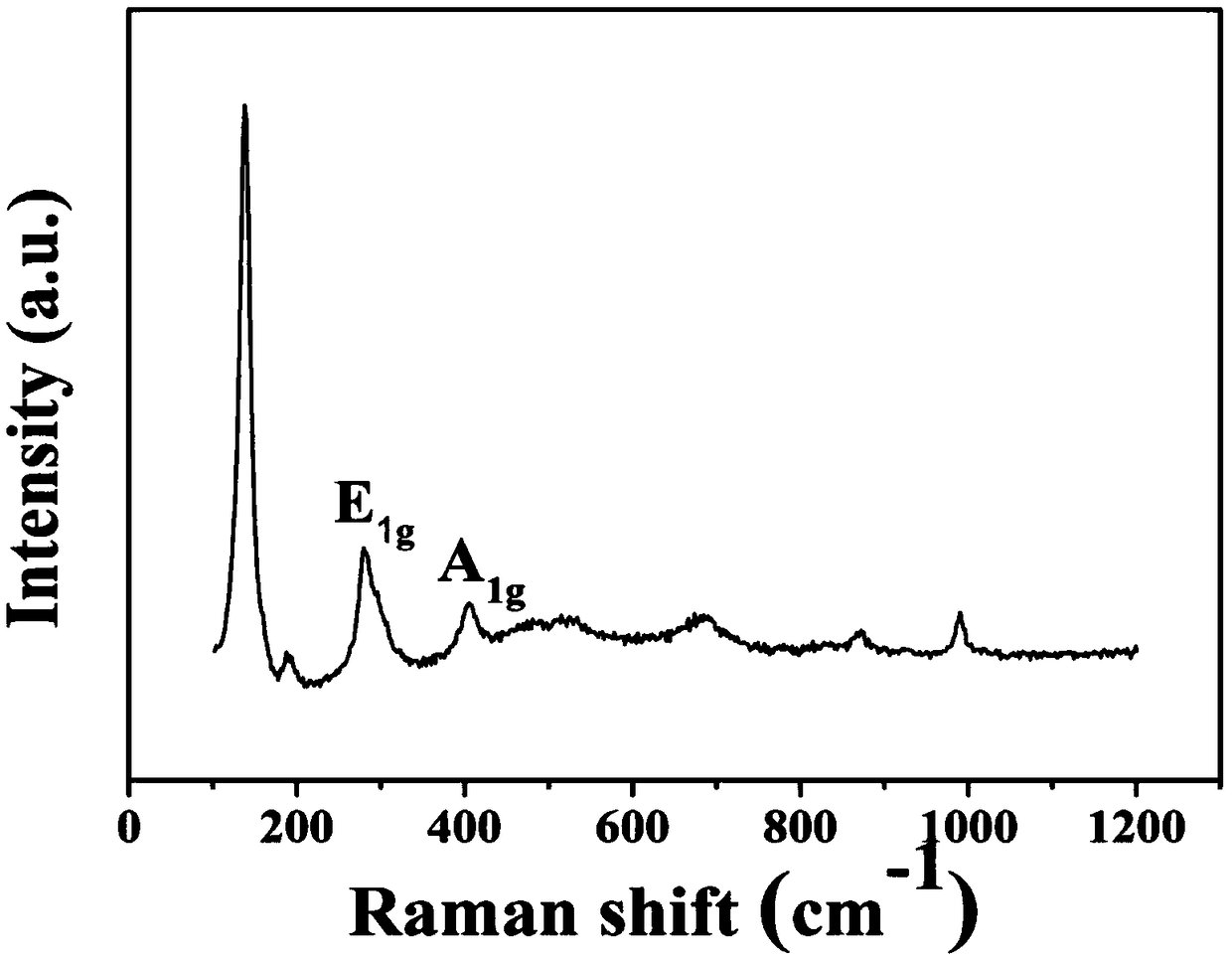

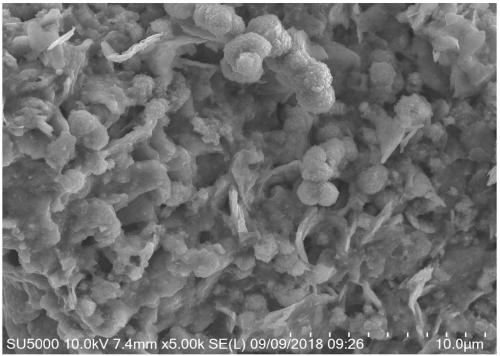

Preparation method and application of aerogel vanadium disulphide

A vanadium disulfide, nanomaterial technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of low specific surface area, easy mixing of impurities, low specific capacity, etc., to achieve large specific surface area, avoid stacking, The effect of high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The preparation method of the airgel-like vanadium disulfide nanomaterial in this embodiment comprises the following steps:

[0026] (1) Weigh 3mmol of ammonium metavanadate and dissolve it in 40ml of deionized water to remove oxygen, add 1ml of ammonia water, stir the solution magnetically until the solution becomes uniform and transparent, then add 15mmol of thioacetamide and continue magnetically stirring for 30 minutes to obtain a uniform solution .

[0027] (2) The uniform solution obtained is transferred to the polytetrafluoroethylene lining of the stainless steel autoclave, tightened and placed in a blast drying oven, and obtained a reaction mixture at 160 degrees Celsius for 24 hours, and the stainless steel autoclave was naturally cooled to After room temperature, the supernatant was removed and the reaction mixture was transferred to a beaker.

[0028] (3) The above reaction mixture was washed three times with deionized water and ethanol respectively, filtere...

Embodiment 2

[0033] The preparation method of the airgel-like vanadium disulfide nanomaterial in this embodiment includes the following steps:

[0034] (1) Weigh 1mmol of ammonium metavanadate and dissolve it in 40ml of deionized water to remove oxygen and add 1.5ml of ammonia water, stir the solution magnetically until the solution becomes uniform and transparent, then add 10mmol of thioacetamide and continue magnetic stirring for 40 minutes to obtain a uniform solution.

[0035] (2) The uniform solution obtained is transferred to the polytetrafluoroethylene lining of the stainless steel autoclave, tightened and placed in a blast drying oven, and obtained a reaction mixture at 150 degrees Celsius for 25 hours, and the stainless steel autoclave was naturally cooled to After room temperature, the supernatant was removed and the reaction mixture was transferred to a beaker.

[0036] (3) The above reaction mixture was washed three times with deionized water and ethanol respectively, filtered...

Embodiment 3

[0041] The preparation method of the airgel-like vanadium disulfide nanomaterial in this embodiment includes the following steps:

[0042] (1) Weigh 2mmol of ammonium metavanadate and dissolve it in 40ml of deionized water to remove oxygen and add 1ml of ammonia water, stir the solution magnetically until the solution becomes uniform and transparent, then add 12mmol of thioacetamide and continue magnetically stirring for 50 minutes to obtain a uniform solution .

[0043] (2) The homogeneous solution obtained is transferred to the polytetrafluoroethylene lining of the stainless steel autoclave, tightened and placed in a blast drying oven, and obtained a reaction mixture at 140 degrees Celsius for 24 hours, and the stainless steel autoclave was naturally cooled to After room temperature, the supernatant was removed and the reaction mixture was transferred to a beaker.

[0044] (3) The above reaction mixture was washed three times with deionized water and ethanol respectively, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com