Printing and dyeing sewage decoloring flocculating agent based on visible light polymerization and preparation method thereof

A decolorizing flocculant, a technology for printing and dyeing sewage, applied in chemical instruments and methods, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. damage and other problems, to achieve the effects of energy saving, high salt tolerance, and short polymerization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

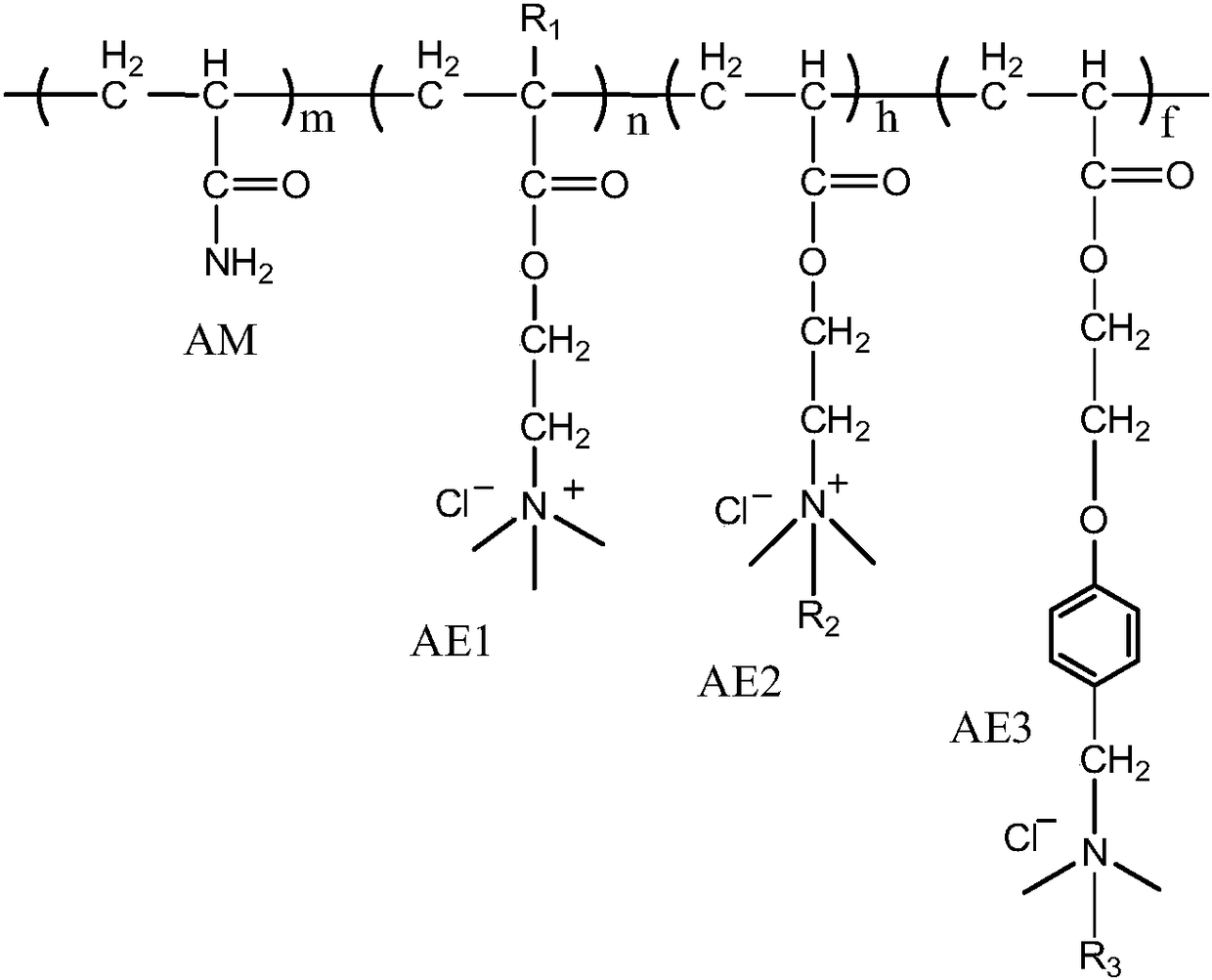

[0060] A preparation method of a printing and dyeing sewage decolorizing flocculant based on visible light polymerization, including the following steps:

[0061] 1) Dissolve the monomers AM, AE1, AE2 and AE3 in water according to the pre-designed ratio, add the pre-dissolved visible light sensitizing dye or pre-dissolved free radical initiator and visible light sensitizing dye, and transfer to the visible light photoreactor In the process, pass nitrogen gas for 30-50min.

[0062] 2) Irradiate with an LED lamp matching the wavelength of the dye for 20-40 minutes. After the temperature no longer rises, keep irradiating for 20-40 seconds. The polymerization reaction is completed and the colloid is obtained.

[0063] 3) The obtained colloid is granulated, dried at 40-70°C, and the finished product is obtained after grinding and sieving.

[0064] Optionally, in step 1), the free radical initiator is a supramolecule composed of water-soluble azo compounds, modified benzophenone wa...

Embodiment 1

[0074] (1) 720g (10.0mol, 40%) acrylamide, 1950g (10.0mol, 40%) acryloyloxyethyltrimethyl ammonium chloride, 1423g (5mol, 20%) acryloyloxyethyl dimethyl P-methyl benzyl ammonium chloride, be dissolved in 17 liters of deionized water, after treating to dissolve completely, add initiator azobisisobutyl ether hydrochloride 1.35g and the squarylium dye 6.8g of above-mentioned code name SQ1, import volume is In a 20-liter photoreactor, pass nitrogen gas at 25°C for 40 minutes, and then irradiate with an LED light source with a wavelength of 650nm for 26 minutes. The thermometer shows that the temperature is 43 degrees. After continuing to irradiate for 30 seconds, the temperature begins to drop, and the light is stopped. Remove the colloid. Use a colloid granulator to granulate with a particle size of 3-8mm. Put it into a 65°C oven, dry it completely after three hours, grind and sieve to obtain the cationic polymer flocculant powder product.

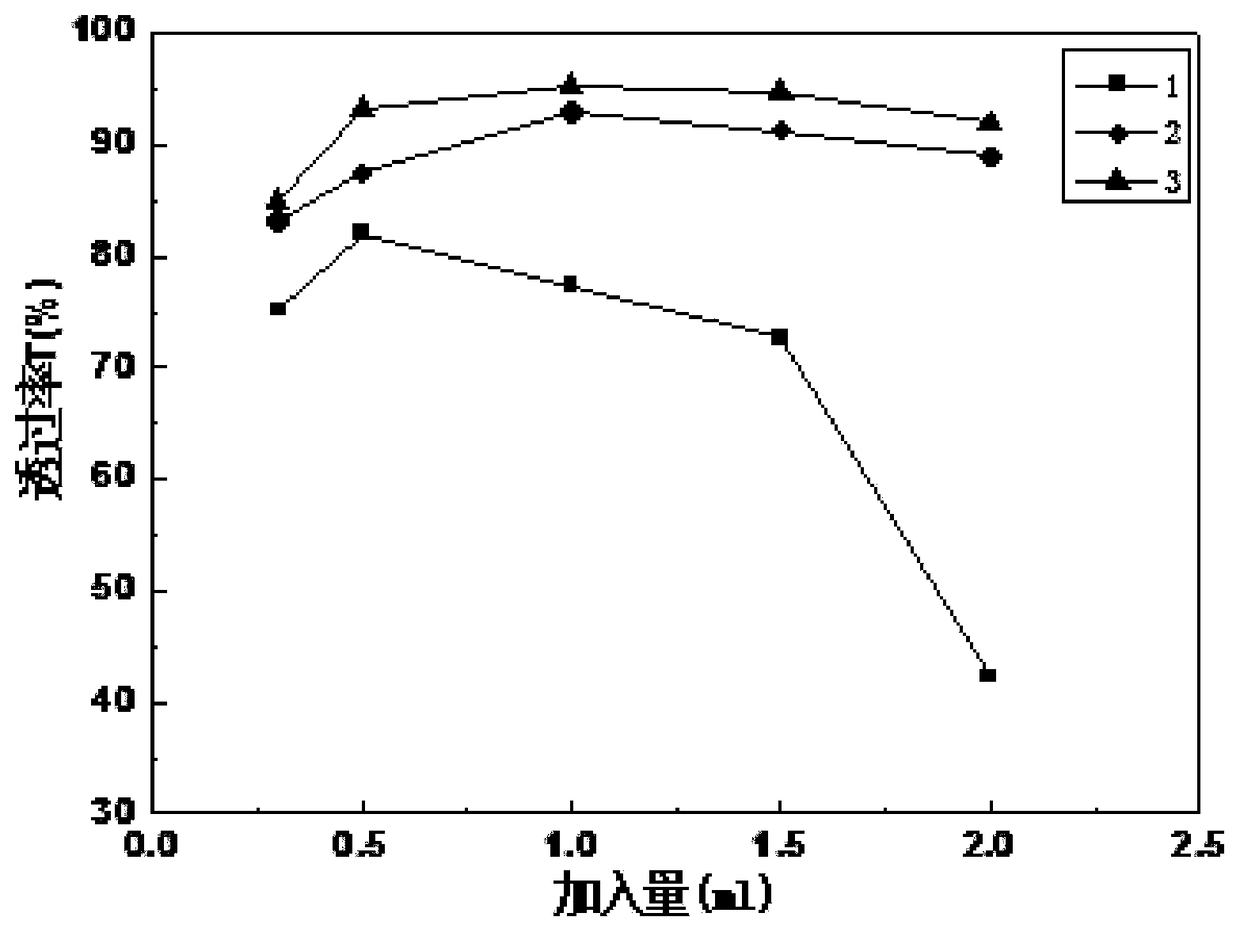

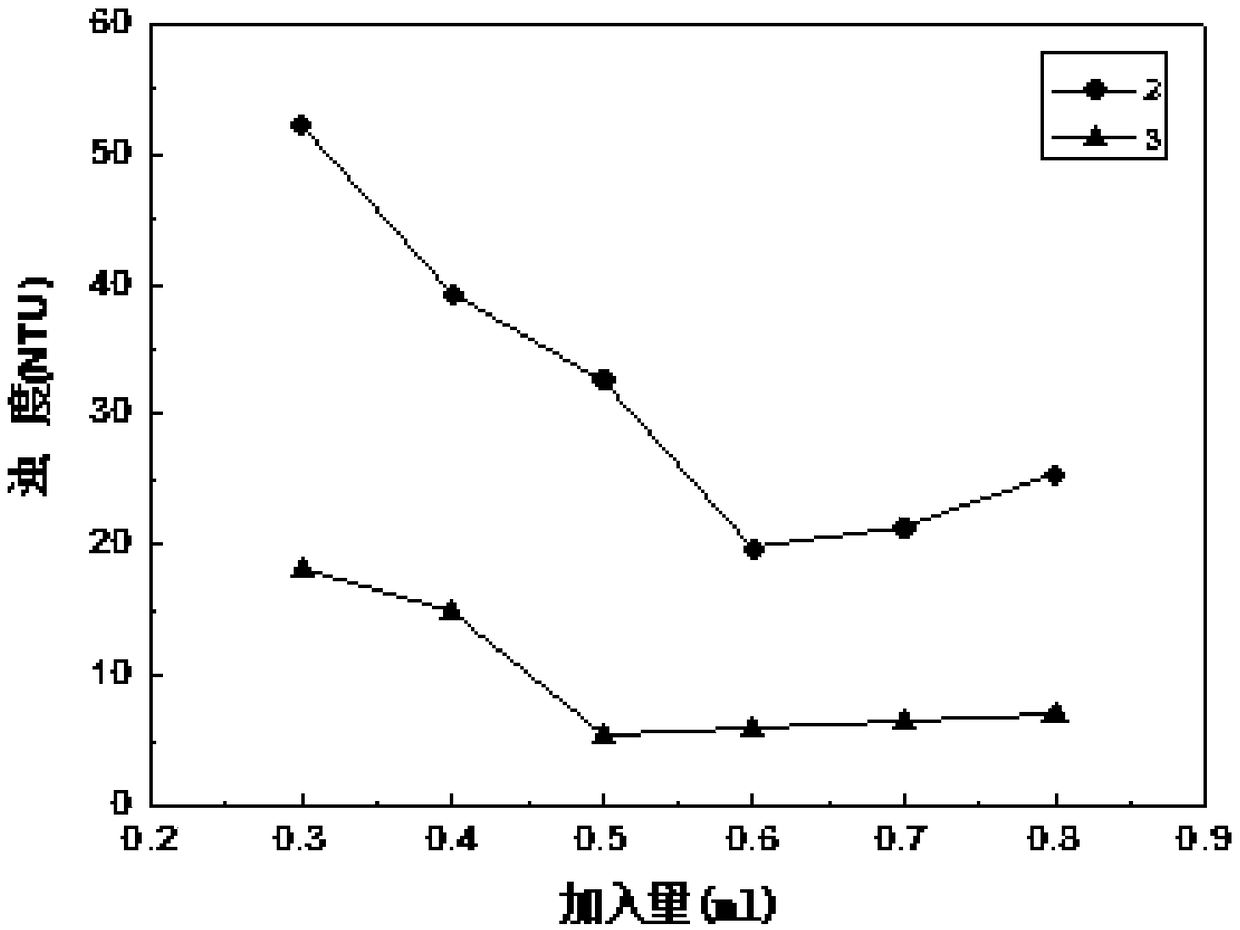

[0075] (2) Take 0.1g of the above-me...

Embodiment 2

[0077] (1) 360g (5mol, 16.7%) of acrylamide, 3100g (15mol, 50%) of methacryloyloxyethyltrimethyl ammonium chloride, 2705g (10mol, 33.3%) of acryloyloxyethyl di-p-benzyl Hydroxyl ammonium chloride, be dissolved in 25 liters of deionized water, after treating to dissolve completely, add initiator BPQ0.8g and the cycloalkane ketone dyestuff 1.80g of above-mentioned code name CP-1, import volume is in the photoreactor of 30 liters, in Nitrogen was passed for 40 minutes at 25°C, and then irradiated with an LED light source with a wavelength of 560nm for 22 minutes. The thermometer showed a temperature of 48°C. After continuing to irradiate for 30 seconds, the temperature began to drop. Stop the light and take out the colloid. Use a colloid granulator to granulate with a particle size of 3-8mm. Put it into a 60°C oven, dry it completely after three hours, grind and sieve to obtain the cationic polymer flocculant powder product.

[0078] (2) Take 0.1g of the above-mentioned cationic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com