Organic waste material aerobic fermented manure quick-composting and element stabilizing method

A technology of organic waste and aerobic fermentation, applied in the field of agricultural resources and environment, can solve the problems of low decomposing degree of compost products, unable to satisfy the rapid decomposing of livestock and poultry manure, stabilization of elements, secondary pollution and other problems at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

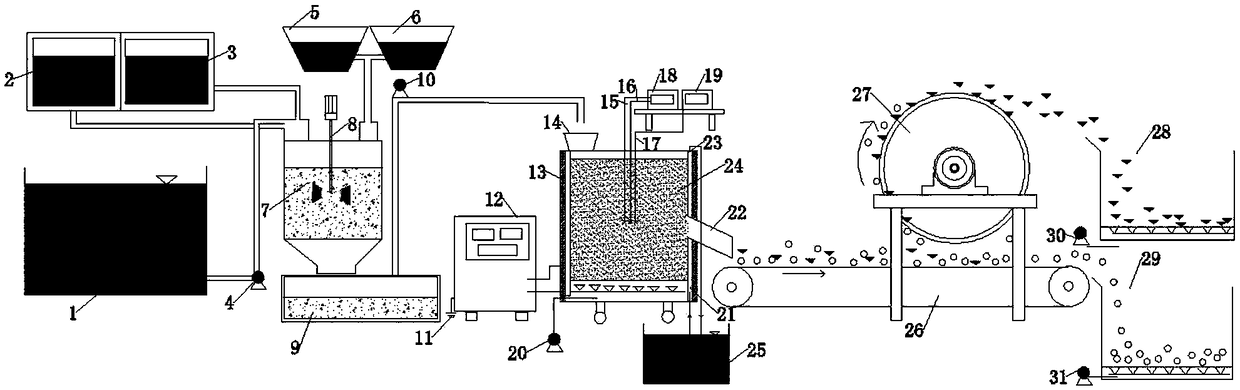

Image

Examples

Embodiment 1

[0065] 1. Preparation of magnetic biochar

[0066] 1. Put the corncob powder passed through a 60-mesh sieve in a muffle furnace (heating rate is 10K / min), and after pre-vacuumizing, under the continuous protection of nitrogen (100mL / min), keep the temperature constant until the temperature rises to 673K Conditional pyrolysis for 5h, then cooled to room temperature.

[0067] 2. Combine the material obtained in step 1 and 1.0mol / L of Fe(NO 3 ) 3 The solution was mixed according to the mass volume ratio of 1:10g / ml, and reacted at a constant temperature of 523K for 30min, and then a sufficient amount of 2mol / L NaOH solution and 0.1mol / L HCl solution were added to the mixture to adjust its pH to 7, and reacted for 12h.

[0068] 3. After completing step 2, wash the sample with deionized water (DI) to remove residual ash on the surface, dry it at a constant temperature of 333K for 24 hours, and seal it in a container until use.

[0069] 2. Mixed composting of pig manure and corn ...

Embodiment 2

[0086] 1. Preparation of magnetic biochar

[0087] 1. Put the corncob powder passed through a 80-mesh sieve in a muffle furnace (heating rate is 20K / min), and after pre-vacuumizing, under the continuous protection of nitrogen (150mL / min), keep the temperature constant until the temperature rises to 973K Conditional pyrolysis for 1h, then cooled to room temperature.

[0088] 2. Combine the material obtained in step 1 and 0.2mol / L of FeCl 3 The solution was mixed according to the mass volume ratio of 0.5:10g / ml, and reacted at a constant temperature of 623K for 60 minutes, and then added enough 1mol / L NaOH solution and 0.5mol / L HCl solution to the mixture to adjust its pH to 6.5, and reacted for 24 hours.

[0089] 3. After completing step 2, wash the sample with deionized water (DI) to remove residual ash on the surface, dry it at a constant temperature of 353K for 24 hours, and seal it in a container until use.

[0090] 2. Mixed compost of chicken manure and wheat straw

[0...

Embodiment 3

[0107] 1. Preparation of magnetic biochar

[0108] 1. Put the corncob powder passed through a 100-mesh sieve in a muffle furnace (heating rate is 30K / min), and after pre-evacuation, under the continuous protection of nitrogen (200mL / min), keep the temperature constant until the temperature rises to 773K Conditional pyrolysis for 4h, then cooled to room temperature.

[0109] 2, the material that step 1 obtains and the Fe of 0.5mol / L 2 (SO 4 ) 3 The solution was mixed according to the mass volume ratio of 2:10g / ml, reacted at a constant temperature of 623K for 30min, and then added enough 3mol / L NaOH solution and 1mol / L HCl solution to the mixture to adjust its pH to 7.5, and reacted for 18h.

[0110] 3. After completing step 2, wash the sample with deionized water (DI) to remove residual ash on the surface, dry it at a constant temperature of 373K for 12 hours, and seal it in a container until use.

[0111] 2. Mixed composting of pig manure and corn stalks

[0112] 1. Add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com