Preparation method and product of heat-conductive thermoplastic vulcanized rubber elastomer material

A rubber elastomer, thermoplastic vulcanization technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of single processing and molding method of rubber materials, affecting the service life of electronic components, difficult to reuse, etc., to achieve excellent green Effects of environmental protection, added value enhancement, and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

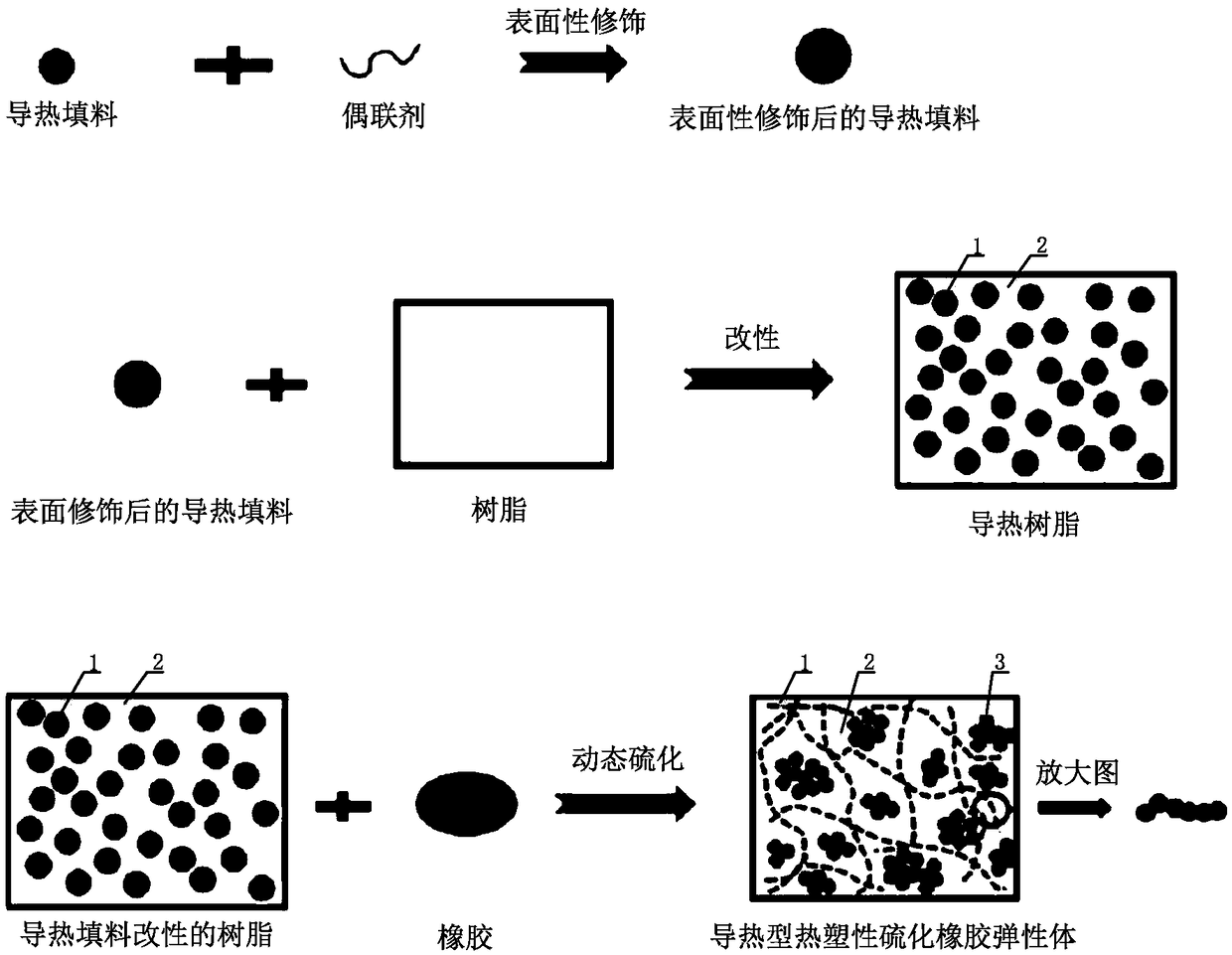

[0027] In a specific embodiment of the present invention, a method for preparing a thermally conductive thermoplastic vulcanizate elastomer material is provided, comprising the following steps: (1) using a coupling agent to modify the surface of a thermally conductive filler and drying it to obtain a modified thermally conductive filler; (2) ) mixing the modified thermally conductive filler with the matrix resin, melt blending, extruding, granulating and drying to obtain thermally conductive resin pellets; (3) mixing the thermally conductive resin pellets with rubber and a vulcanization system, and performing Dynamic vulcanization reaction and extrusion granulation to obtain thermally conductive thermoplastic vulcanized rubber elastomer material.

[0028] In a specific embodiment of the present invention, the thermally conductive filler is carbon nanotube, graphene, graphite, carbon black, silicon carbide, boron carbide, chromium carbide, tungsten carbide, silicon nitride, boro...

Embodiment 1

[0041] The method for preparing a thermally conductive thermoplastic vulcanized rubber elastomer material in this embodiment, selects polypropylene as the resin phase, EPDM rubber as the rubber phase, and aluminum nitride as the thermally conductive filler, including the following steps:

[0042] (1) First, the aluminum nitride powder is calcined in a boron nitride crucible at 1600-1850°C, and after cooling, the aluminum nitride powder is treated with a tetrabutyl titanate coupling agent, and then the aluminum nitride powder is heated in a drum at 60°C. Dry in the air oven for 6 hours;

[0043] (2) According to the ratio of 100:20, the polypropylene pellets and the treated aluminum nitride powder are melt-blended, extruded, water-cooled, and granulated in a twin-screw extruder at 200°C at a speed of 60r / min. Prepared thermally conductive polypropylene pellets;

[0044] (3) Then put the thermally conductive polypropylene pellets and EPDM raw rubber in a blast oven and dry at 8...

Embodiment 2

[0048] The method for preparing the thermally conductive thermoplastic vulcanized rubber elastomer material in this embodiment, selects polypropylene as the resin phase, EPDM rubber as the rubber phase, and graphite sheet as the thermally conductive filler, including the following steps:

[0049] (1) Firstly, the surface of the graphite sheet was modified by titanate coupling agent NDZ101, and then dried in a blast oven at 60°C for 6 hours;

[0050] (2) Melt blending, extruding, water cooling, and granulation in a twin-screw extruder at 200°C in a ratio of 100:15 to the polypropylene pellets and the modified graphite flakes to prepare thermally conductive polypropylene pellets material;

[0051] (3) Then put the thermally conductive polypropylene pellets and EPDM raw rubber in a blast oven and dry at 80°C for 2 hours, take out the EPDM raw rubber and place it in an internal mixer at 150°C for 80r masticate for 5min at a rotating speed of 1 / min to obtain EPDM plasticized rubbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com