Highly-transparent anti-ultraviolet nano-cellulose composite film and production method thereof

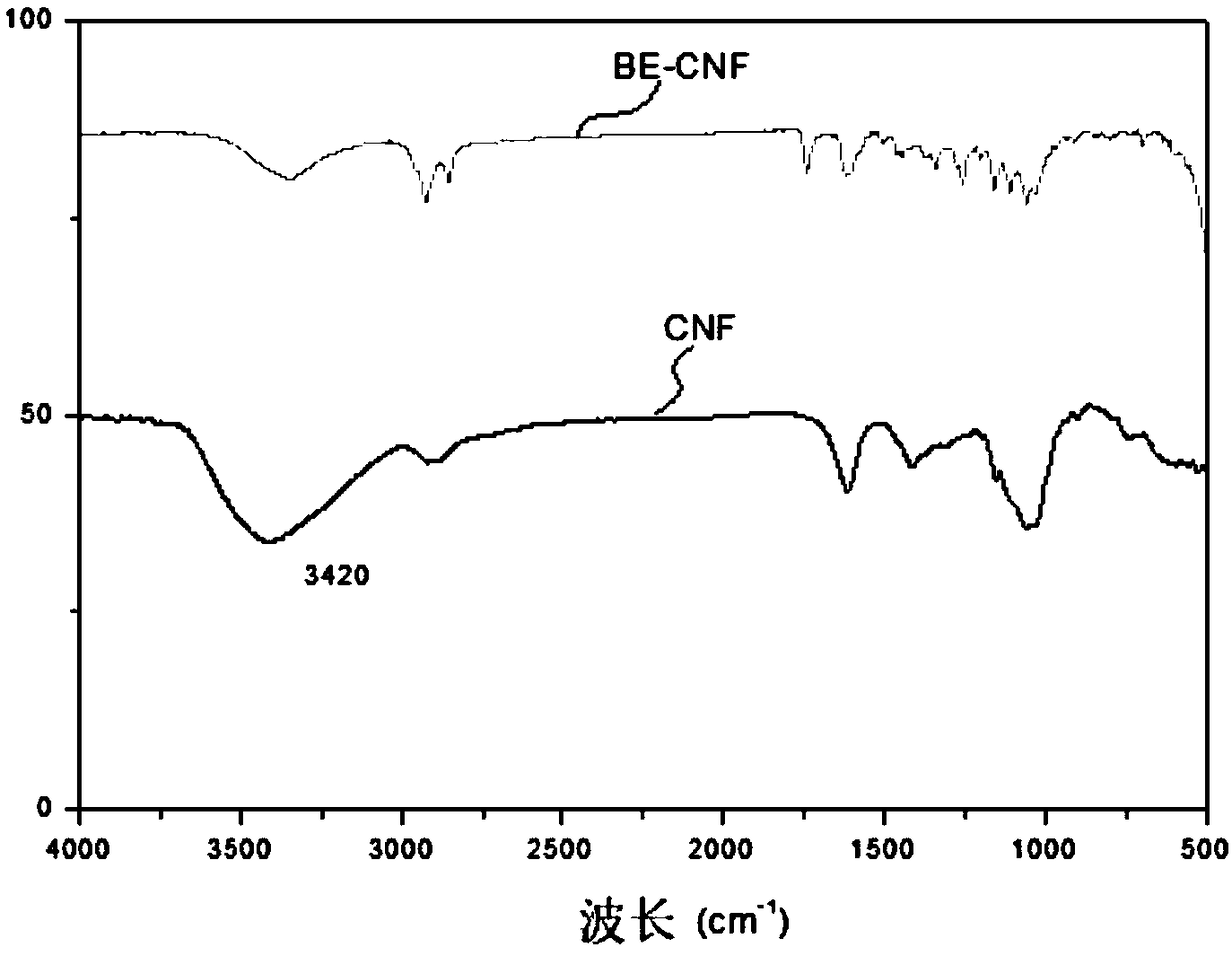

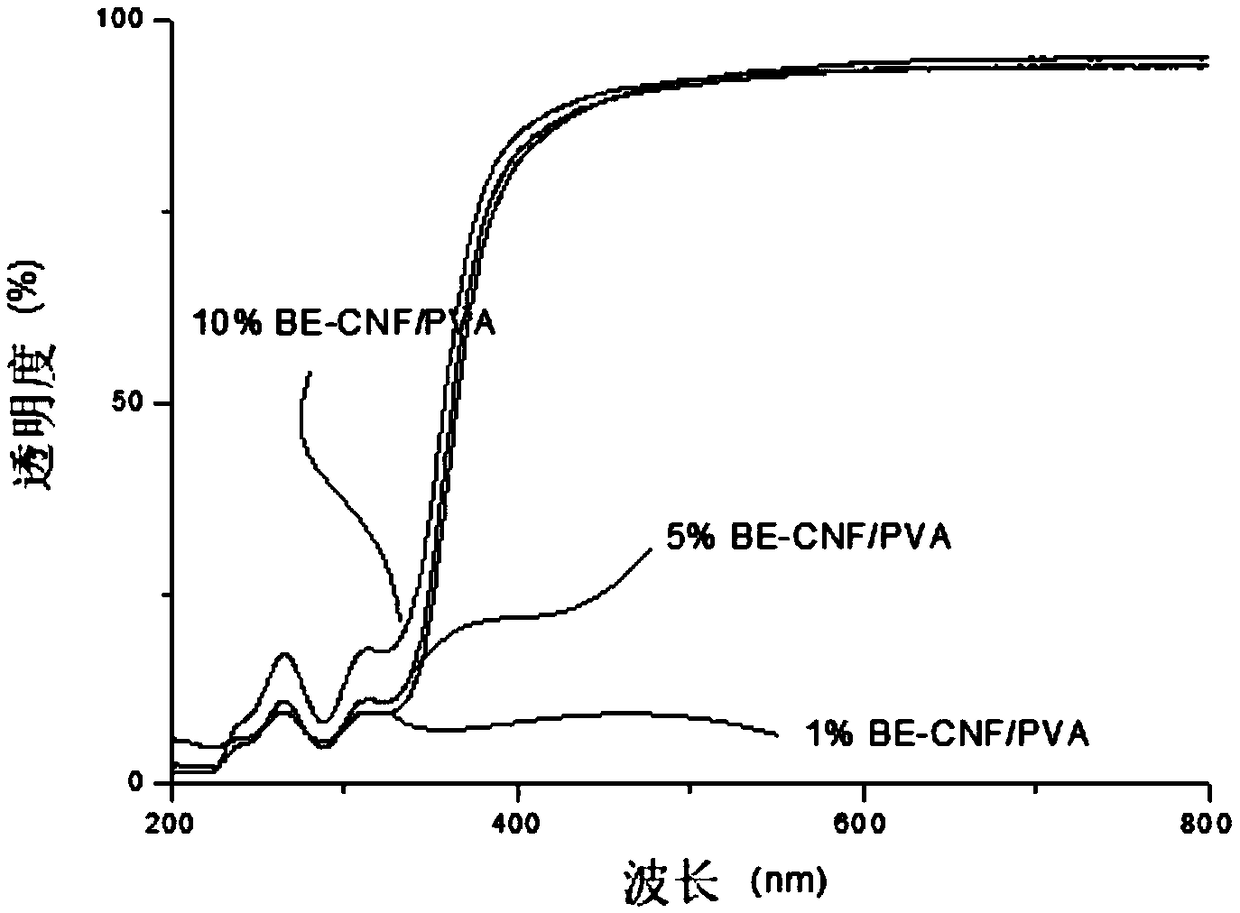

A nanocellulose and nanofiber technology is applied in the field of highly transparent UV-resistant nanocellulose composite film and its preparation, which can solve the problems of cumbersome steps and harsh reaction conditions, and achieves high-efficiency UV absorption, simple modification method, and mechanical properties. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A highly transparent anti-ultraviolet nano-cellulose composite film is prepared by the following steps:

[0040] 1) The cellulose nanofiber aqueous solution with a mass percentage concentration of 0.1% is centrifuged and washed with ethanol and acetone several times to remove water, and redispersed in dimethyl sulfoxide with a mass percentage concentration of 0.1%;

[0041] 2) Add 2-hydroxy-4-methoxybenzophenone and epoxidized soybean oil to the product obtained in step 1), continue to pass nitrogen, control the temperature at 120°C, and react for 1 hour; wherein, 2-hydroxy-4 - the mass ratio of methoxybenzophenone and epoxidized soybean oil is 1: 1, and the mass ratio of cellulose nanofibers and 2-hydroxyl-4-methoxybenzophenone is 1: 1;

[0042] 3) After the reaction in step 2), acetone was added to the reacted mixture, stirred at a high speed, and then centrifuged at a speed of 12500 r / min in a desktop centrifuge. Wash away excess 2-hydroxy-4-methoxybenzophenone and ...

Embodiment 2

[0046] A highly transparent anti-ultraviolet nano-cellulose composite film is prepared by the following steps:

[0047] 1) The cellulose nanofiber aqueous solution with a mass percentage concentration of 0.25% is centrifuged and washed with ethanol and acetone several times to remove water, and redispersed in dimethyl sulfoxide with a mass percentage concentration of 0.25%;

[0048] 2) Add 2-hydroxy-4-methoxybenzophenone and epoxidized soybean oil to the product obtained in step 1), continue to pass nitrogen, control the temperature at 120°C, and react for 1 hour; wherein, 2-hydroxy-4 - the mass ratio of methoxybenzophenone and epoxidized soybean oil is 1: 1, and the mass ratio of cellulose nanofibers and 2-hydroxyl-4-methoxybenzophenone is 1: 1;

[0049] 3) After the reaction in step 2), acetone was added to the reacted mixture, stirred at a high speed, and then centrifuged at a speed of 12500 r / min in a desktop centrifuge. Wash away excess 2-hydroxy-4-methoxybenzophenone an...

Embodiment 3

[0053] A highly transparent anti-ultraviolet nano-cellulose composite film is prepared by the following steps:

[0054] 1) The cellulose nanofiber aqueous solution with a mass percentage concentration of 0.5% is centrifuged with ethanol and acetone to remove water, and redispersed in dimethyl sulfoxide with a mass percentage concentration of 0.5%;

[0055] 2) Add 2-hydroxy-4-methoxybenzophenone and epoxidized soybean oil to the product obtained in step 1), continue to pass nitrogen, control the temperature at 120°C, and react for 1 hour; wherein, 2-hydroxy-4 - the mass ratio of methoxybenzophenone and epoxidized soybean oil is 1: 1, and the mass ratio of cellulose nanofibers and 2-hydroxyl-4-methoxybenzophenone is 1: 1;

[0056] 3) After the reaction in step 2), acetone was added to the reacted mixture, stirred at a high speed, and then centrifuged at a speed of 12500 r / min in a desktop centrifuge. Wash away excess 2-hydroxy-4-methoxybenzophenone and epoxidized soybean oil wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com