(Ti, La) (C, N)-based metal ceramic composite material and preparation method thereof

A ceramic composite material and composite material technology, applied in the field of metal-ceramic composite materials and their preparation, can solve the problems of increasing the amount of binder phase and rare earth elements, affecting the development, complex process, etc., to achieve wettability and interface Improve the bonding strength, enhance the bonding force of phase boundary and grain boundary, and strengthen the effect of cermet bonding phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

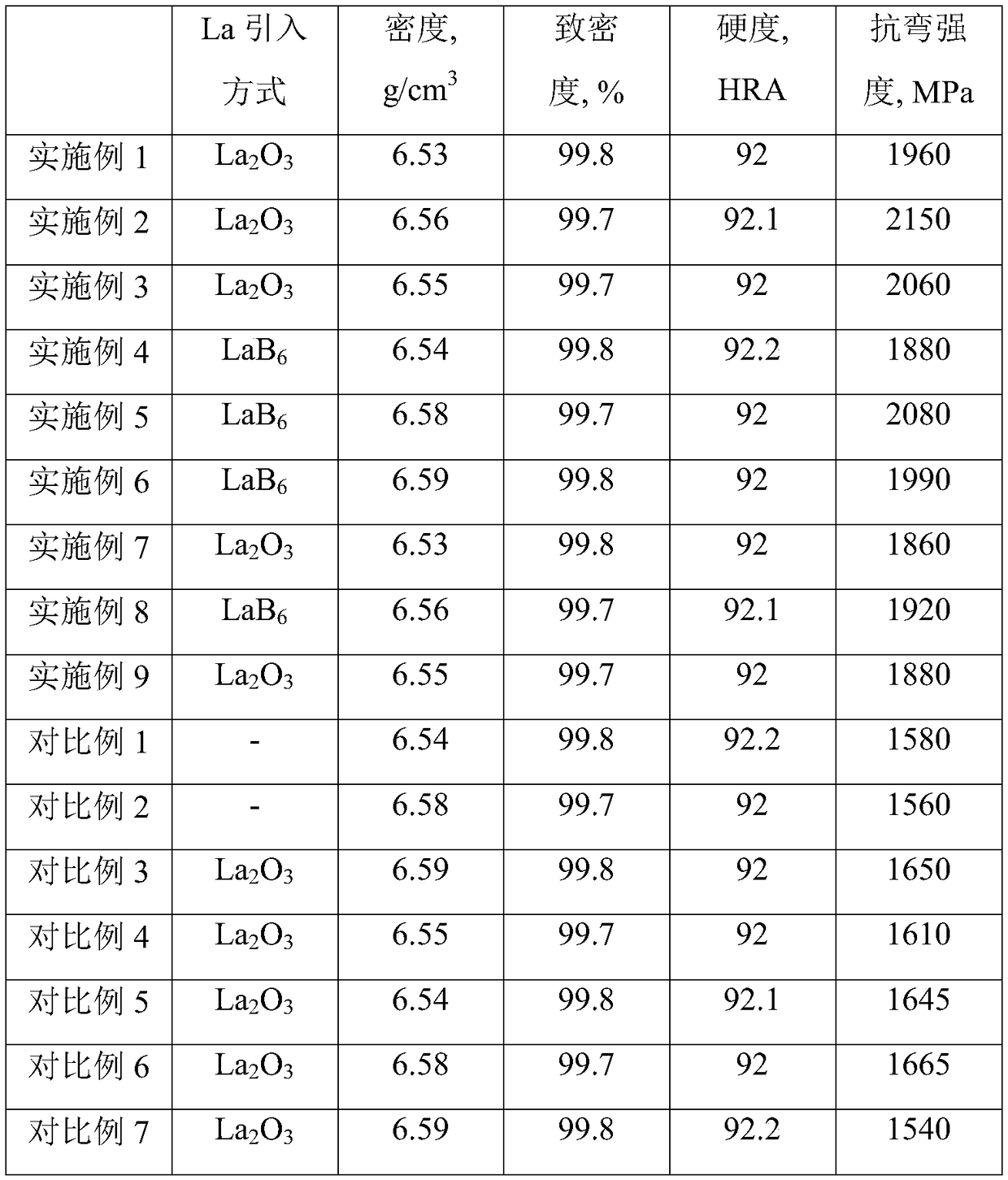

Examples

preparation example Construction

[0058] The preparation method of above-mentioned (Ti, La) (C, N) solid solution powder, comprises the following steps:

[0059] (1) The above weight percentage components are batched, and dry-milled by a ball mill at a speed of 60rpm, and the dry-milling time is 4h;

[0060] (2) Pass the powder material after ball milling in step (1) through a 200-mesh screen, and then undergo high-temperature carbonitriding in a graphite carbon tube furnace; wherein, the high-temperature carbonitriding process parameters are: the boat loading capacity is 1.5- 2.0kg, the temperature is 1600-1800°C, the speed of pushing the boat is 2-4 hours / boat, nitrogen is the protective atmosphere.

[0061] (3) Pass the powder material after high temperature carbonitriding in step (2) through a 200-mesh sieve again to obtain (Ti,La)(C,N) solid solution powder.

Embodiment 1

[0063] This embodiment provides a (Ti, La) (C, N)-based cermet composite material, which is composed of a hard phase and a binder phase, wherein the hard phase is composed of (Ti, La) (C, N), TaC , TiC, NbC, WC, Mo 2 C and Cr 3 C 2 Composition, the binder phase is composed of Co and Ni; the composite material is made of the following raw materials in weight percentage: (Ti,La)(C,N) is 52%, TaC is 2%, TiC is 2%, NbC is 2% , WC is 17.5%, Mo 2 C is 8%, Cr 3 C 2 0.5%, Co 8%, Ni 8%; solid solution powder (Ti, La) (C, N) element component weight percentage: La 0.05%, C 8.5%, N 10.5%, the rest Ti; Among them, the average particle size of (Ti, La) (C, N) solid solution powder is 1.2 μm, the average particle size of Co powder is 1.2 μm, the average particle size of Ni powder is 2 μm, and the average particle size of other powders mentioned above The diameter is less than 4 μm.

[0064] The preparation method of the above-mentioned (Ti, La) (C, N)-based cermet composite material ...

Embodiment 2

[0071] This embodiment provides a (Ti, La) (C, N)-based cermet composite material. The difference from Example 1 is that the composite material of this embodiment is made of the following raw materials in weight percentage: (Ti, La)(C,N) is 53%, TaC is 2%, TiC is 2%, NbC is 2%, WC is 16.5%, Mo 2 C is 8%, Cr 3 C 2 is 0.5%, Co is 9%, and Ni is 7%; the element component weight percent in the solid solution powder (Ti, La) (C, N) of the present embodiment is as follows: La is 0.15%, C is 9.5%, N is 10.5%, the balance being Ti.

[0072] The preparation method of (Ti,La)(C,N)-based cermet composite material in this example refers to the operation steps of Example 1, the main difference is that in step S2, PEG is selected as the forming agent, and the amount of PEG added is the total amount of raw materials 3.6%, the process parameters of ball milling are: use WC-8%Co cemented carbide balls with a diameter of 10mm for ball milling, use absolute ethanol as the ball milling medium, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com