Preparation method and application of iron carbide-cobalt/nitrogen doped carbon nano composite material

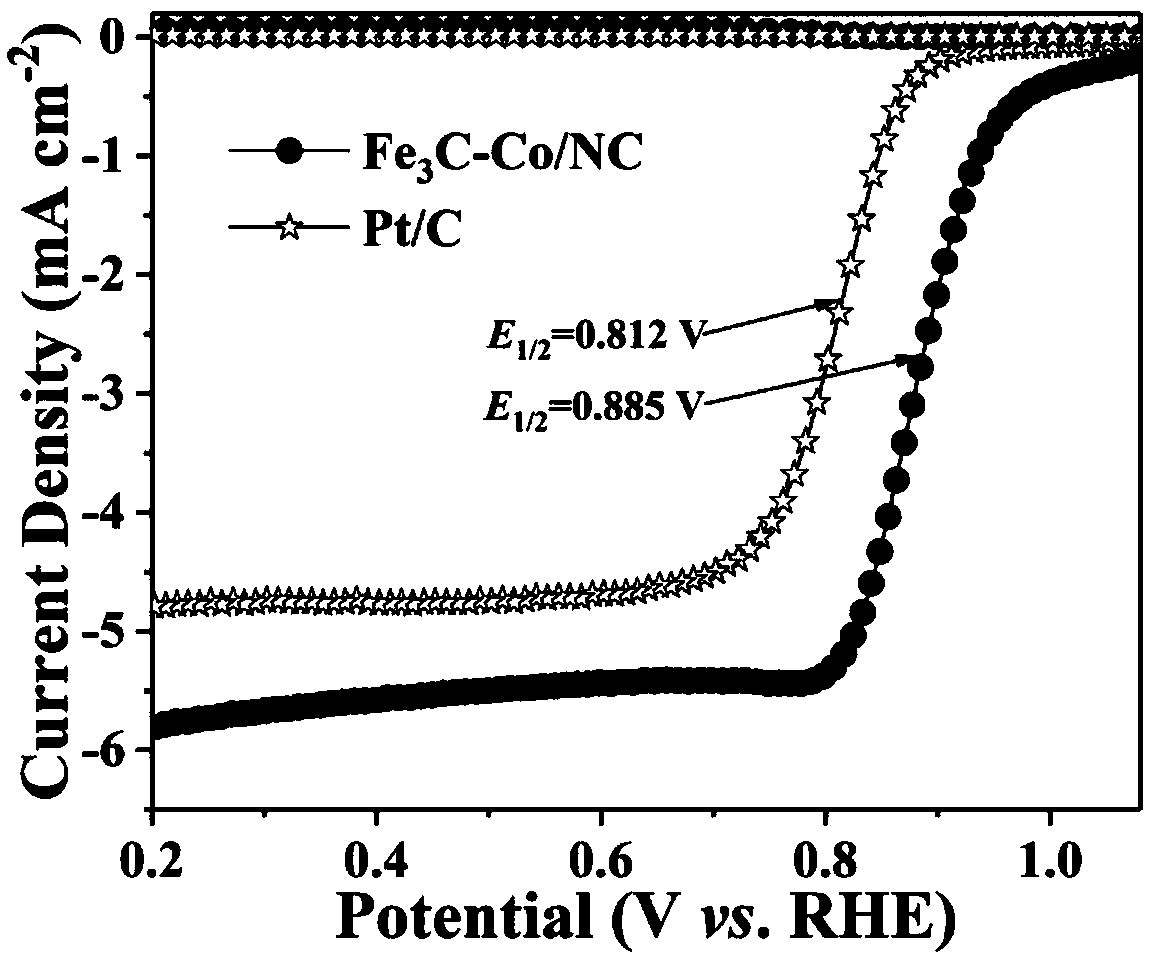

A nano-composite material and nitrogen-doped carbon technology, applied in structural parts, electrolytic components, electrolytic processes, etc., to achieve excellent catalytic performance, excellent electrical conductivity, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0050] The preparation process and steps in this embodiment are as follows:

[0051] (1) Add 6g of P123, polyethylene oxide-propylene oxide-ethylene oxide and 14.5ml concentration of 37% concentrated hydrochloric acid into 217ml deionized water, then add 7.4ml of n-butanol, at 35°C Stirred under low temperature for 1h, then added 13.8ml of tetraethyl orthosilicate dropwise, and continued to stir at 35°C for 24h; then transferred it to a polytetrafluoroethylene reactor, and reacted at 100°C for 24h; then The reacted solution was centrifuged with water and ethanol, washed, and vacuum-dried at 60°C for 24 hours; finally, the obtained white powder was annealed in air at 500°C for 3 hours, and then naturally cooled to room temperature;

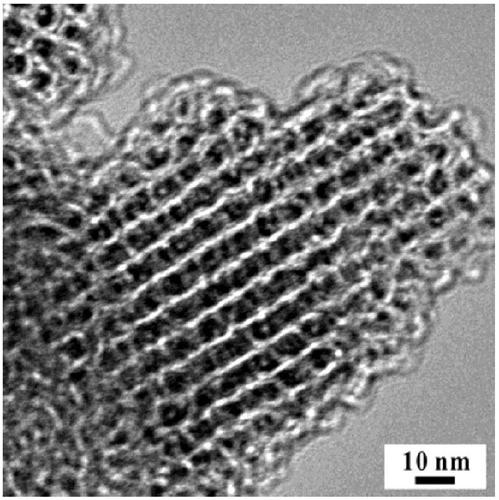

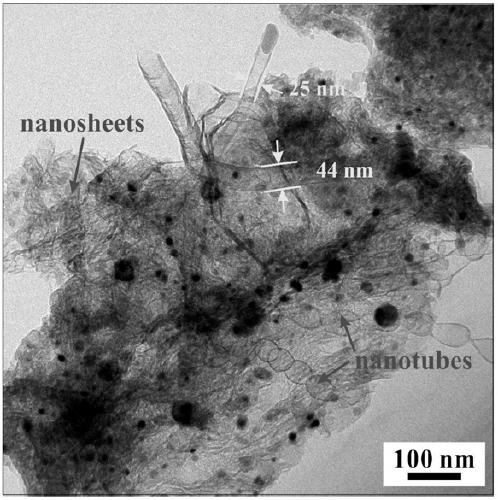

[0052] (2) 0.118g Co(NO 3 ) 2 ·6H 2 O, 0.382g Fe(NO 3 ) 3 9H 2 O, the melamine of 5.44g, the mesoporous KIT-6 silicon template that 1g makes and the P123 of 2.8g join in the mixed solution of 28ml water and ethanol, carry out the stirring of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com