A composite material of multi-stage pore carbon and cobalt sulfide, preparation method thereof and lithium sulfide battery cathode material containing composite material and lithium sulfide battery

A composite material, multi-level pore technology, applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve problems such as unfavorable elemental sulfur, shuttle effect, easy to fall off, etc., achieve good electrochemical performance, improve electrochemical performance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

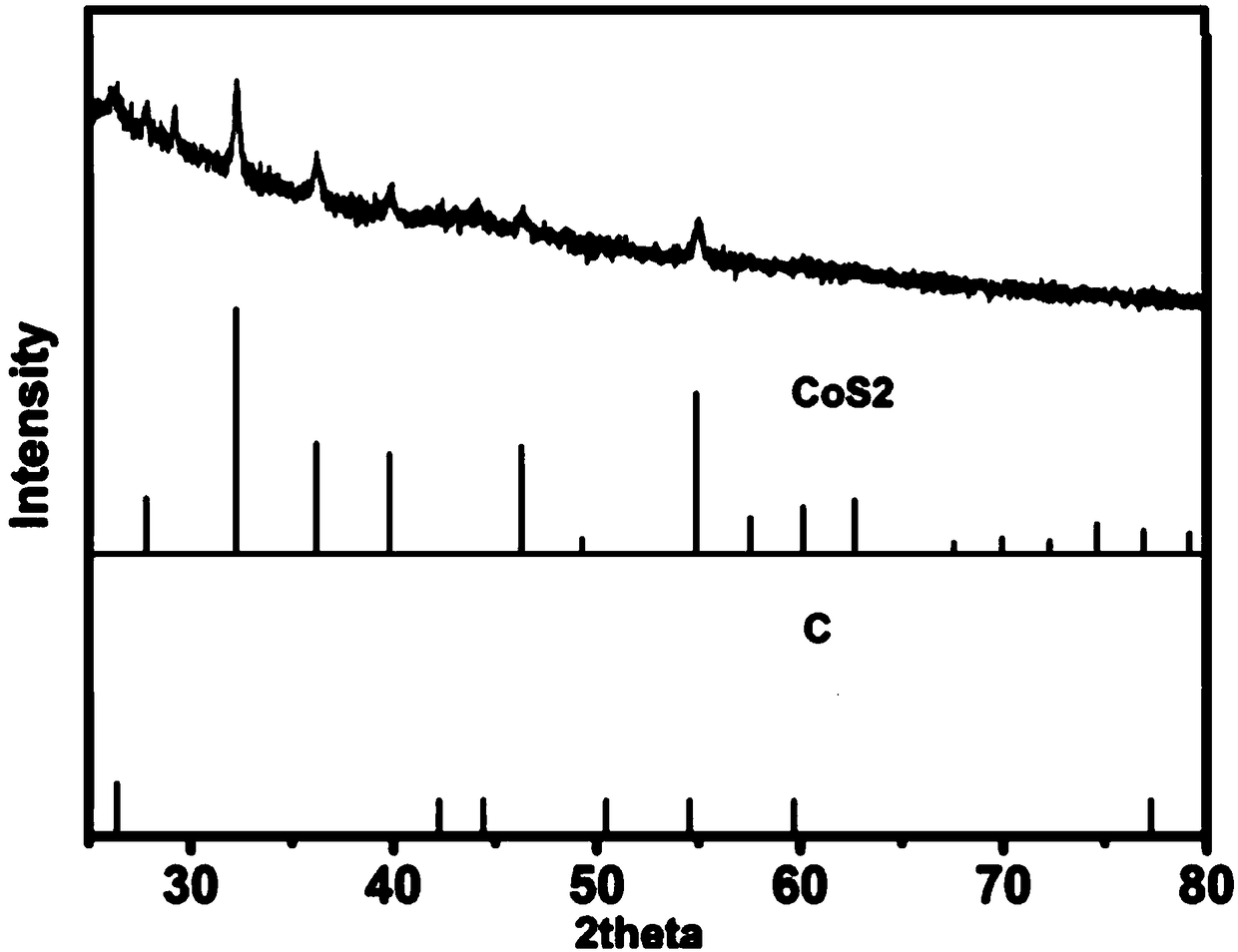

[0031] The existing carbon and metal oxide or metal sulfide composite materials and cobalt sulfide have low sulfur loading capacity, and the electrochemical performance of lithium-sulfur batteries is not good after being used in lithium-sulfur batteries. In order to overcome this defect, the present invention provides a new A preparation method of a composite material of porous carbon and cobalt sulfide, the method comprising the following steps:

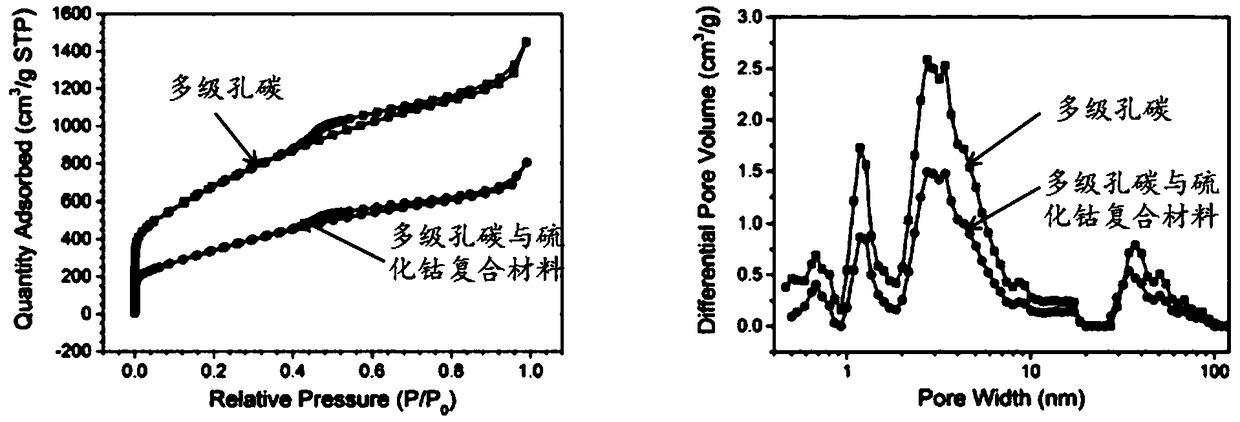

[0032] (1) Disperse the hierarchical porous carbon in a strong acid solution to connect the hierarchical porous carbon to carboxyl groups or disperse the hierarchical porous carbon in a strong alkali solution to connect the hierarchical porous carbon to hydroxyl groups to obtain functionalized hierarchical pores Carbon, the functionalized hierarchical porous carbon is cleaned to neutral and then dried; among them, the hierarchical porous carbon has micropores, mesopores and macropores, and the specific surface area of the hierarchi...

Embodiment 1

[0057] An embodiment of the composite material of hierarchical porous carbon and cobalt sulfide and its preparation method of the present invention, the preparation method of the composite material of hierarchical porous carbon and cobalt sulfide described in this embodiment is:

[0058] (1) Disperse the hierarchical porous carbon in sodium hydroxide solution, the concentration of sodium hydroxide in the sodium hydroxide solution is 2mol / L, then put it into a high-pressure hydrothermal kettle, and conduct a hydrothermal reaction at 180°C for 2h to make the multi-stage The porous carbon is connected with hydroxyl groups, and is suction-filtered to obtain a functionalized hierarchical porous carbon; the functionalized hierarchical porous carbon is washed with secondary deionized water until the pH value is 7, and then dried in an oven;

[0059] (2) Take 100 mg of the dried functionalized hierarchical porous carbon obtained in step (1), disperse it in an ethylene glycol solution, ...

Embodiment 2

[0072] An embodiment of the composite material of hierarchical porous carbon and cobalt sulfide and its preparation method of the present invention, the preparation method of the composite material of hierarchical porous carbon and cobalt sulfide described in this embodiment is:

[0073] (1) Disperse the hierarchical porous carbon in a sulfuric acid solution, the concentration of hydrogen ions in the sulfuric acid solution is 6mol / L, and then stir in the air at a temperature of 80°C for 8h, so that the hierarchical porous carbon is connected to a carboxyl group, and suction filtered, Obtaining the functionalized hierarchical porous carbon; washing the functionalized hierarchical porous carbon with secondary deionized water until the pH value is 7, and drying in an oven;

[0074] (2) Take 100 mg of the dried functionalized hierarchical porous carbon obtained in step (1), disperse it in an ethanol solution, ultrasonicate for 60 minutes, add cobalt chloride and sodium sulfide in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com