Chestnut storage method

A chestnut and granule technology, which is applied to the preservation of edible seeds, preservation of seeds by drying, and preservation of seeds with a protective layer, etc., can solve the problems of shortened storage time, mold, and loss of internal nutrients, and extend the storage period , reduce loss, reduce the effect of nutrient loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

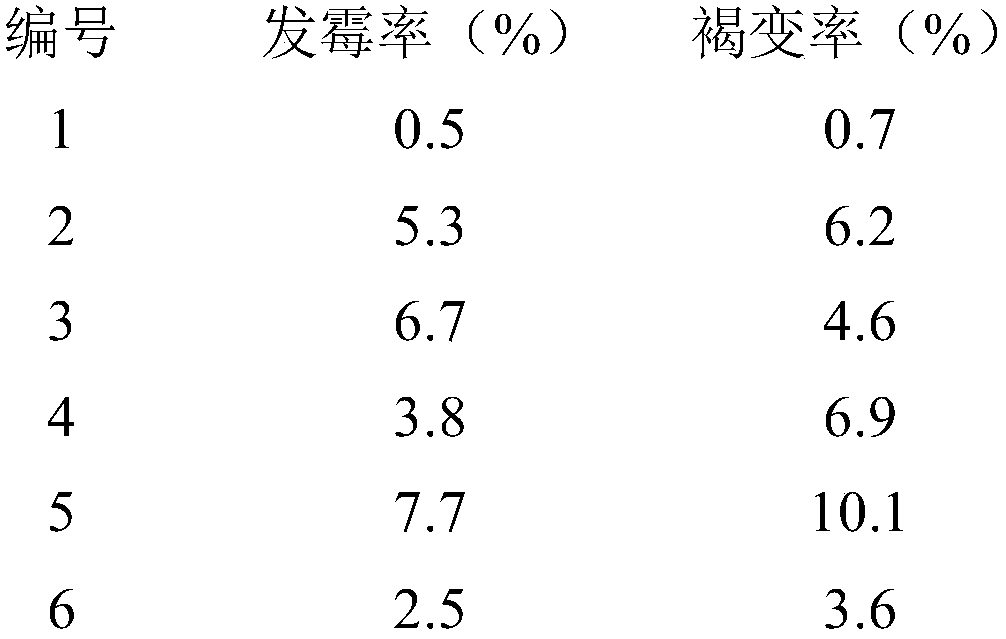

Examples

Embodiment 1

[0027] The present embodiment provides a kind of chestnut storage method, and concrete process is as follows:

[0028] 1. Cleaning: Take 100 parts of freshly picked chestnuts, remove wormholes and unfulfilled particles on the surface, add 500 parts of water, stir, remove floating chestnut particles, wash the remaining particles, remove surface impurities, remove and drain;

[0029] 2. Sterilization: Take 10 parts of edible alkali, 20 parts of common salt and 500 parts of water to dissolve, add the drained chestnuts to the alkali aqueous solution and soak for 10 minutes, heat to 40°C, and perform ultrasonic treatment. The ultrasonic power is 200W and the frequency is 50kHz. Ultrasonic time is 1h;

[0030] 3. Drying: Drain the ultrasonically treated chestnuts, place them in a low-temperature, vacuum drying room, and perform low-temperature drying treatment at low temperature, the drying temperature is -5°C, and the treatment time is 10 hours. After the treatment, the water conte...

Embodiment 2

[0035] The present embodiment provides a kind of chestnut storage method, and concrete process is as follows:

[0036] 1. Cleaning: Take 100 parts of freshly picked chestnuts, remove wormholes and unfulfilled particles on the surface, add 500 parts of water, stir, remove floating chestnut particles, wash the remaining particles, remove surface impurities, remove and drain;

[0037] 2. Sterilization: Take 13 parts of edible alkali, 25 parts of common salt and 500 parts of water to dissolve, add the drained chestnuts to the alkali aqueous solution and soak for 13 minutes, heat to 45°C, and perform ultrasonic treatment. The ultrasonic power is 230W and the frequency is 55kHz. Ultrasonic time is 1.5h;

[0038] 3. Drying: Drain the ultrasonically treated chestnuts, place them in a low-temperature, vacuum drying room, and perform low-temperature drying treatment. The drying temperature is -4°C, and the treatment time is 11 hours. After the treatment, the water content of the chestnu...

Embodiment 3

[0043] The present embodiment provides a kind of chestnut storage method, and concrete process is as follows:

[0044] 1. Cleaning: Take 100 parts of freshly picked chestnuts, remove wormholes and unfulfilled particles on the surface, add 500 parts of water, stir, remove floating chestnut particles, wash the remaining particles, remove surface impurities, remove and drain;

[0045] 2. Sterilization: Take 15 parts of edible alkali, 30 parts of common salt and 500 parts of water to dissolve, add the drained chestnuts to the alkali aqueous solution and soak for 15 minutes, heat to 50°C, and perform ultrasonic treatment. The ultrasonic power is 250W and the frequency is 60kHz. Ultrasonic time is 2h;

[0046] 3. Drying: Drain the ultrasonically treated chestnuts, place them in a low-temperature, vacuum drying room, and perform low-temperature drying treatment. The drying temperature is -3°C, and the treatment time is 12 hours. After the treatment, the water content of the chestnuts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap