Ceramic bond diamond grinding wheel

A vitrified bond and diamond grinding wheel technology is applied to diamond grinding wheels. In the field, it can solve the problems of high efficiency and grinding high-quality stainless steel parts, etc., and achieve the effect of reducing production cost, good cooling effect, and improving heat transfer and heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

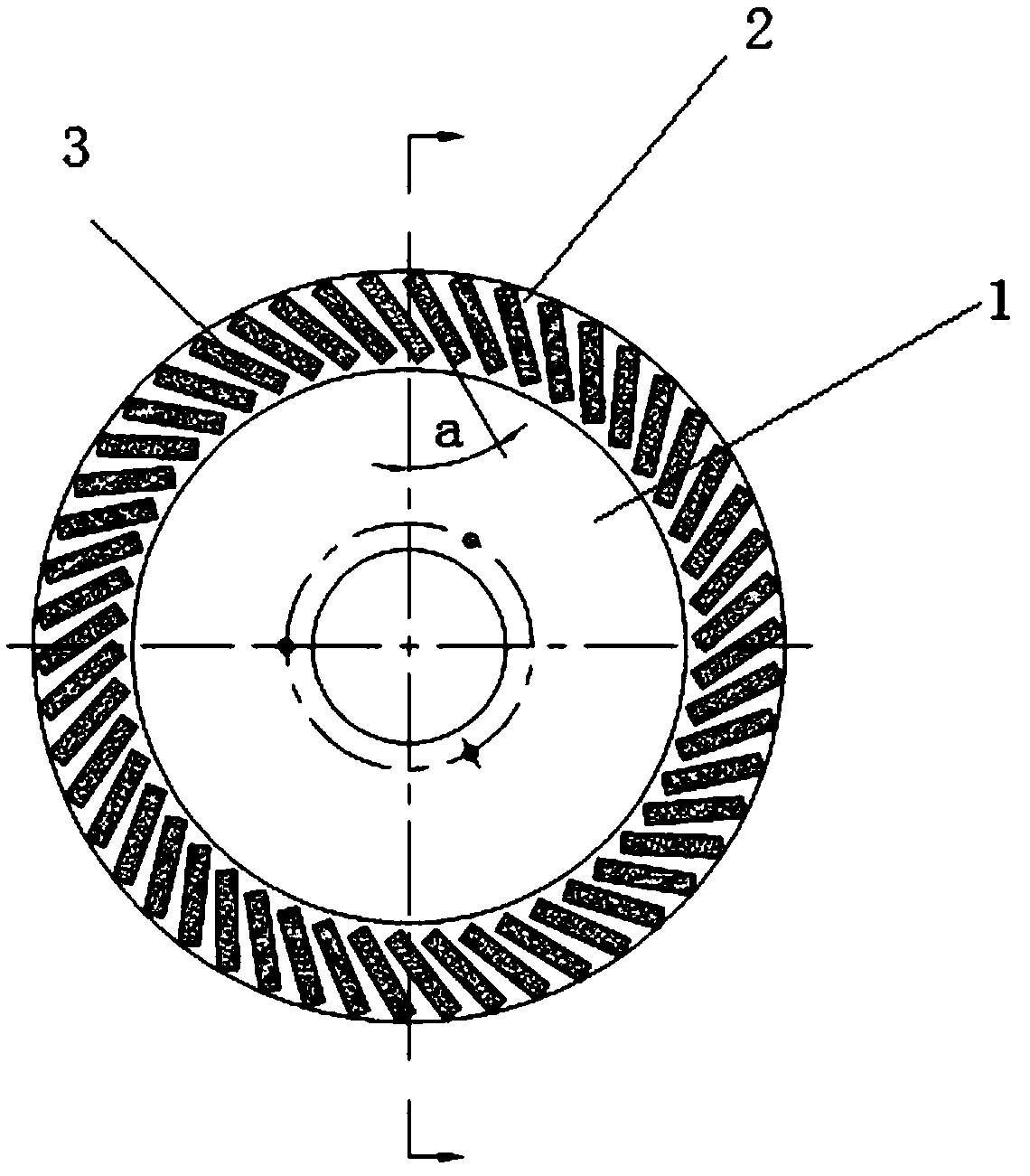

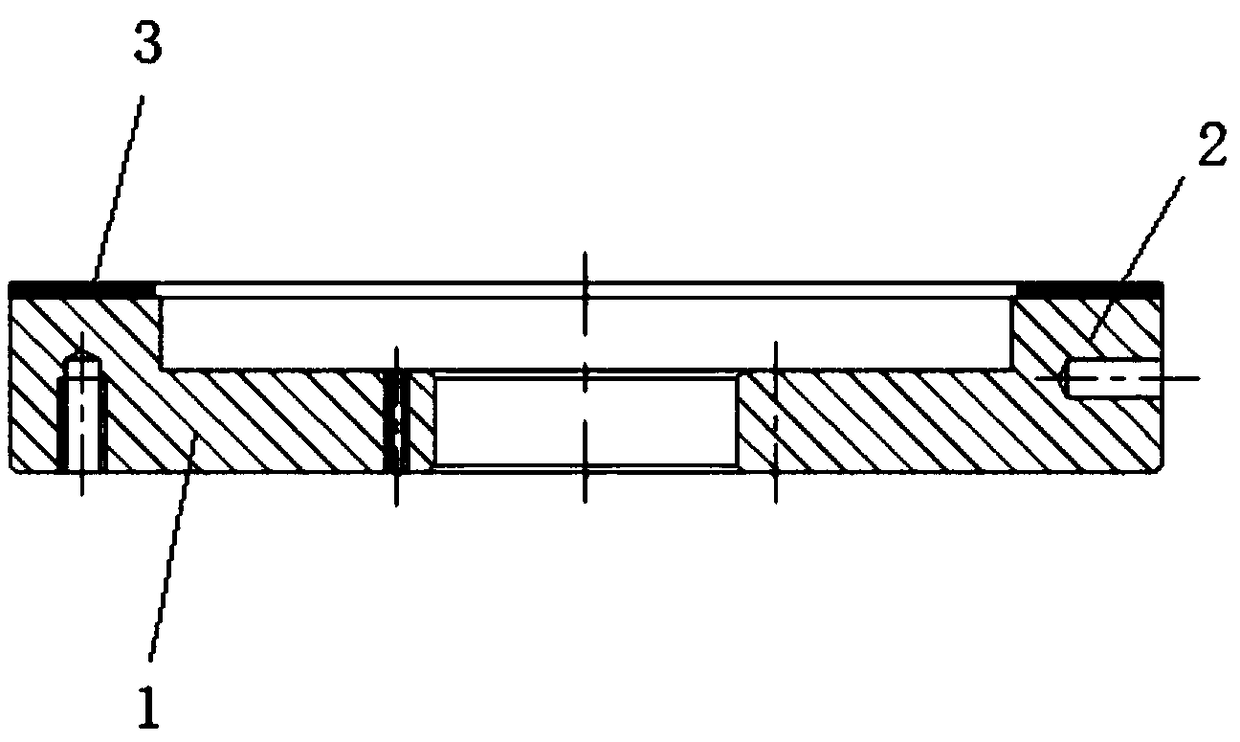

[0018] The substrate is an aluminum substrate, and the abrasive layer is 30 vitrified bond diamond blocks obliquely inlaid on the end surface of the substrate to form a ring-shaped working layer. a is 33°;

[0019] The material composition of described vitrified bond diamond block is by weight: diamond abrasive 30, vitrified bond 25, auxiliary abrasive 2, filler 2, additive 30;

[0020] The vitrified bond is microceramic glass; the auxiliary abrasive is alumina;

[0021] The filler is one or more types of iron oxide;

[0022] The additives are dextrin powder and walnut shell powder.

[0023] The mesh number of the ceramic bond is 300 mesh.

[0024] The mesh number of the additive is 300 mesh.

[0025] The mesh number of the filler is 300 mesh.

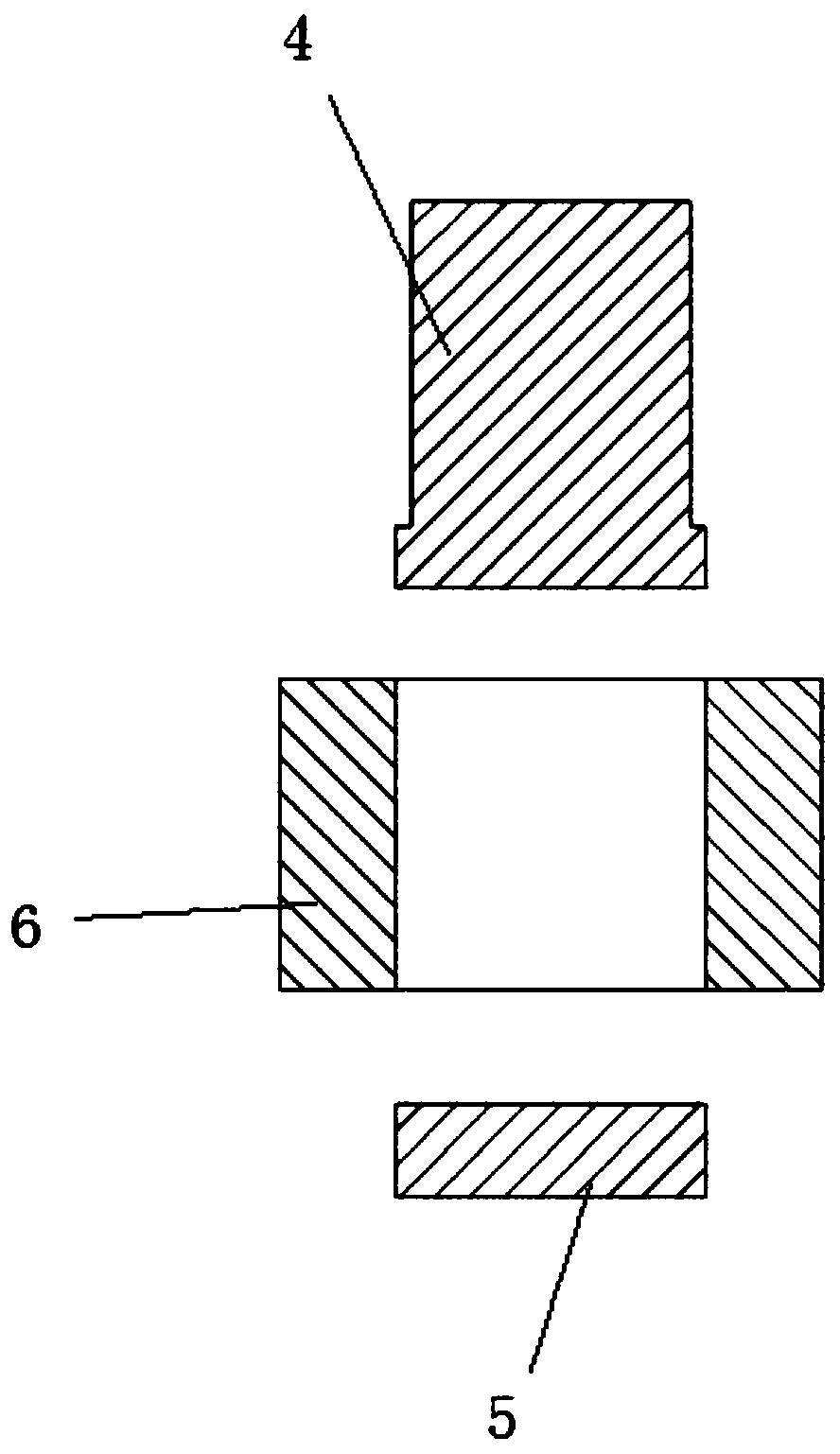

[0026] Select diamond abrasives, auxiliary abrasives, fillers, vitrified bonds and additives according to the above proportions, put them into the mixer together with water and stir evenly; process the upper pressure ring, lower p...

Embodiment 2

[0029] The substrate is an aluminum substrate, and the abrasive layer is 30 vitrified bond diamond blocks obliquely inlaid on the end surface of the substrate to form a ring-shaped working layer. a is 30°;

[0030] The material composition of described vitrified bond diamond block is by weight: diamond abrasive 20, vitrified bond 30, auxiliary abrasive 25, additive 25;

[0031] The vitrified bond is microceramic glass; the auxiliary abrasive is silicon carbide and boron carbide;

[0032] The filler is iron oxide, zinc oxide, chromium oxide;

[0033] The additive is ethyl maltol.

[0034] The mesh number of the ceramic bond is 300 mesh.

[0035] The mesh number of the additive is 300 mesh.

[0036] The mesh number of the filler is 300 mesh.

[0037] Select diamond abrasives, auxiliary abrasives, fillers, vitrified bonds and additives according to the above proportions, put them into the mixer together with water and stir evenly; process the upper pressure ring, lower press...

Embodiment 3

[0040] The substrate is an aluminum substrate, and the abrasive layer is 30 vitrified bond diamond blocks obliquely inlaid on the end surface of the substrate to form a ring-shaped working layer. a is 35°;

[0041] The material composition of described vitrified bond diamond block is by weight: diamond abrasive 25, vitrified bond 20, auxiliary abrasive 30, filler 3, additive 35;

[0042] The vitrified bond is microceramic glass; the auxiliary abrasive is one or more of alumina and brown corundum;

[0043] The filler is iron oxide, zinc oxide, chromium oxide;

[0044] The additives are dextrin powder, walnut shell powder and ethyl maltol.

[0045] The mesh number of the ceramic bond is 300 mesh.

[0046] The mesh number of the additive is 300 mesh.

[0047] The mesh number of the filler is 300 mesh.

[0048] Select diamond abrasives, auxiliary abrasives, fillers, vitrified bonds and additives according to the above proportions, put them into the mixer together with water a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com