A control method for microcracks on the surface of pitch-based spherical activated carbon

A technology of spherical activated carbon and control methods, which is applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as microcracks in asphalt balls containing holes, microcracks in pitch balls containing naphthalene, and escape of fine naphthalene, so as to avoid Effects of microcracks, suppression of surface microcracks, and improvement of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

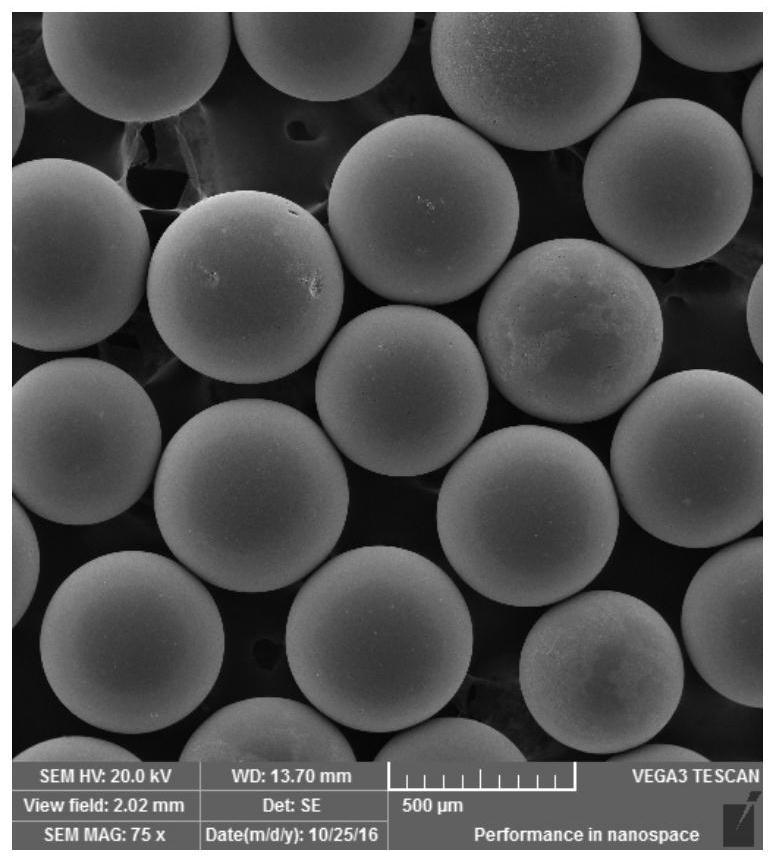

[0048] Using high softening point coal tar pitch with a softening point of 268°C as raw material, use a twin-screw extruder to uniformly mix 1000Kg of high softening point coal tar pitch and 250Kg of refined naphthalene to make naphthalene pitch strips with a diameter of 3mm. Using a roller crusher, crush 1250Kg of naphthalene pitch-containing strips into naphthalene pitch-containing particles with a diameter of 0.6-0.8mm. 3000L of deionized water, 20Kg of polyvinyl alcohol, and 500Kg of naphthalene pitch-containing particles were successively placed in a 5000L high-pressure reactor, and 99.99% high-purity nitrogen gas was introduced to keep the pressure in the reactor at 0.5 MPa. Then the reaction medium was heated to 109°C at a heating rate of 5°C / min and kept at a constant temperature for 30 minutes, and then naturally cooled to 50°C. Although the obtained product is a naphthalene-pitch ball with a diameter of 0.6-0.8 mm, there are certain microcracks on the surface, such a...

Embodiment 2

[0050] Using high softening point coal tar pitch with a softening point of 268°C as raw material, use twin-screw extruder to uniformly mix 1000Kg high softening point coal tar pitch and 250Kg refined naphthalene to make naphthalene pitch strips with a diameter of 3mm. Using a roller crusher, crush 1250Kg of naphthalene pitch-containing strips into naphthalene pitch-containing particles with a diameter of 0.6-0.8 mm. 3000L of deionized water, 20Kg of polyvinyl alcohol, 5Kg of refined naphthalene, and 500Kg of naphthalene-containing pitch particles were successively placed in a 5000L high-pressure reactor, and 99.99% high-purity nitrogen gas was introduced to keep the pressure in the reactor at 0.5MPa. Then the reaction medium was heated to 109°C at a heating rate of 5°C / min and kept at a constant temperature for 30 minutes, and then naturally cooled to 50°C. The resulting product is a naphthalene pitch-containing ball with a diameter of 0.6 to 0.8 mm, but the surface of the nap...

Embodiment 3

[0052] Place the naphthalene pitch-containing balls prepared in [Example 2] in a blast oven and dry at 60°C for 2 hours. Before drying, the surface of naphthalene pitch-containing spheres was smooth, but after drying, although the macroscopic morphology of naphthalene pitch-containing spheres did not change, slight microcracks appeared on the surface, such as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com