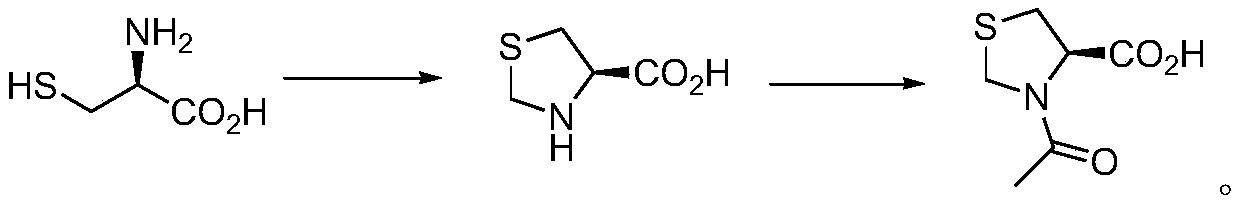

Synthetic method for efficiently preparing folcisteine

A synthesis method and a technology for halifolin, applied in the direction of organic chemistry and the like, can solve the problems of complex process route, high production cost, poor product quality, etc., and achieve the effects of improving reaction yield, yield improvement and good crystal form.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0031] Add 300 kilograms of tap water, 92 kilograms of 37% formaldehyde solution and 100 kilograms of L-cysteine hydrochloride monohydrate in a 500-liter reactor. Within the range of 7-10, after the reaction of the raw materials is detected by pointing the plate, the temperature is raised to 50°C, and acetic anhydride and saturated sodium carbonate solution are added dropwise at the same time to maintain the pH value of the reaction system within the range of 7-10. After the addition is completed, the reaction is continued for 1 After 1 hour, point the plate to detect that the raw materials have reacted completely, add concentrated hydrochloric acid dropwise, adjust the pH of the system to 5-6, add 20 kg of activated carbon, heat and decolorize, beat the plate frame to reflux and filter, add concentrated hydrochloric acid dropwise to the filtrate to adjust the pH to 1-2, Under slow stirring, the temperature was lowered for crystallization, the precipitated solid was centrifug...

experiment example 2

[0034] Add 300 kilograms of tap water, 50 kilograms of 37% formaldehyde solution and 100 kilograms of L-cysteine hydrochloride monohydrate in a 500-liter reactor, after stirring and clarifying at room temperature, add dropwise saturated sodium carbonate solution to maintain the pH value of the reaction system Within the range of 7-10, after the reaction of the raw materials is detected by pointing the plate, the temperature is raised to 50°C, and acetic anhydride and saturated sodium carbonate solution are added dropwise at the same time to maintain the pH value of the reaction system within the range of 7-10. After the addition is completed, the reaction is continued for 1 After 1 hour, point the plate to detect that the raw materials have reacted completely, add concentrated hydrochloric acid dropwise, adjust the pH of the system to 5-6, add 20 kg of activated carbon, heat and decolorize, beat the plate frame to reflux and filter, add concentrated hydrochloric acid dropwise ...

experiment example 3

[0037] Add 280 kilograms of tap water, 48 kilograms of 37% formaldehyde solution and 100 kilograms of L-cysteine hydrochloride monohydrate in a 500-liter reactor. Within the range of 7-10, after the reaction of the raw materials is detected by pointing the plate, the temperature is raised to 50°C, and acetic anhydride and saturated sodium carbonate solution are added dropwise at the same time to maintain the pH value of the reaction system within the range of 7-10. After the addition is completed, the reaction is continued for 1 Hour. After the reaction of the raw materials is completely detected by pointing the plate, add concentrated hydrochloric acid dropwise to adjust the pH of the system to 5-6, add 20 kg of activated carbon, heat and decolorize, beat the plate frame to reflux and filter, add concentrated hydrochloric acid to the filtrate to adjust the pH to 1-2, and stir slowly Next, cool down and crystallize. The precipitated solid was centrifuged, dried, and package...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com