Preparation method of cationic polystyrene resin

A polystyrene resin, cationic technology, applied in the field of preparation of cationic polystyrene resin, can solve the problems of low surface charge, high cost, environmental pollution, etc., achieve high grafting rate, avoid adverse effects, and less dosage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The invention discloses a preparation method of cationic polystyrene resin, said method comprising the following steps:

[0023] Step 1. Pretreatment of unmodified polystyrene resin: Weigh a certain amount of polystyrene resin microspheres, add dichloromethane to swell for 10-14 hours, and then use tetrahydrofuran, ultrapure water, absolute ethanol and methanol Wash and filter 2-4 times, and finally vacuum-dry at 40°C to constant weight;

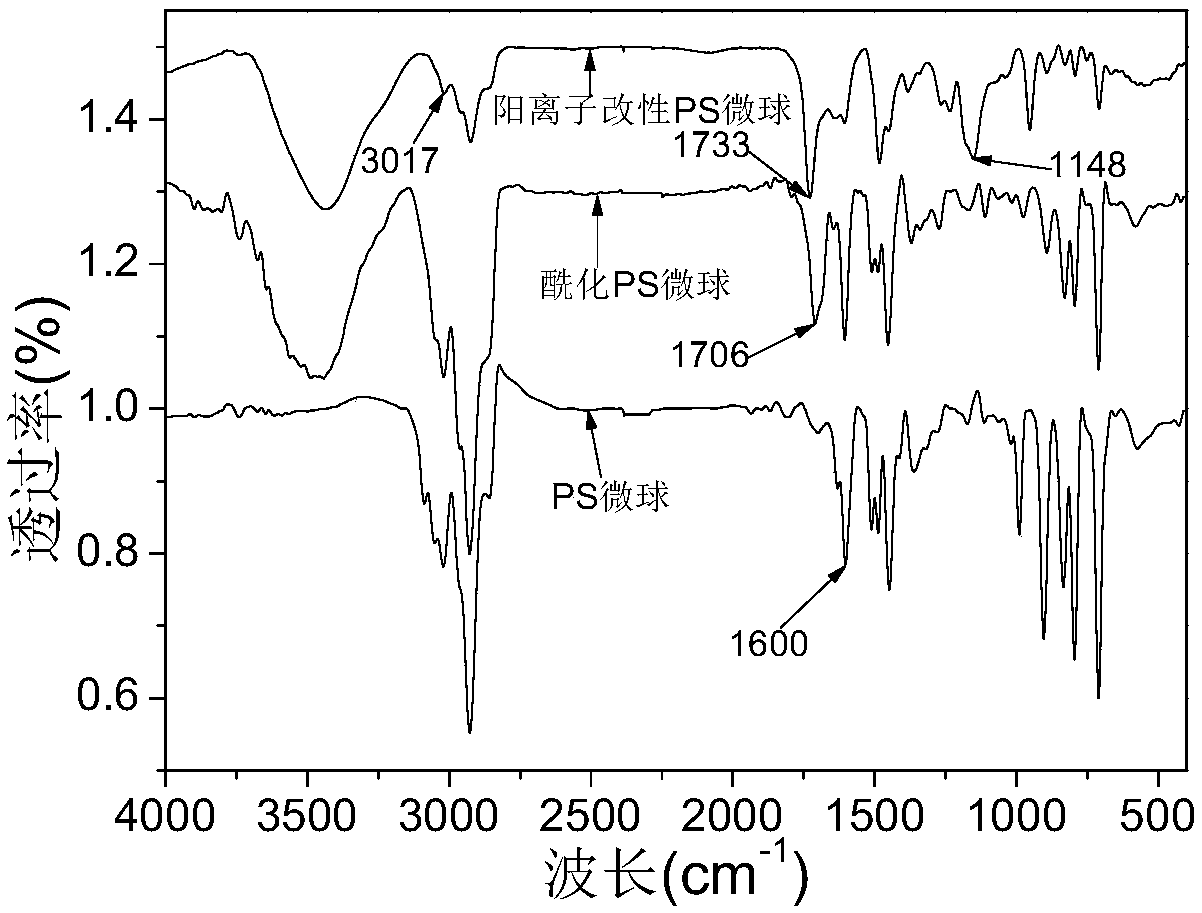

[0024] Step 2, acylation of polystyrene resin: Weigh the polystyrene resin microspheres treated in step 1, add carbon disulfide to swell for 12 hours, add 2-bromo-2-methylpropionyl bromide dropwise, and batch by batch Slowly add aluminum tribromide, under the condition of 30-70°C, condense and reflux for 60-300 minutes, stop the reaction with ultrapure water, cool to room temperature, wash and filter with methanol and ultrapure water 3-5 times, and finally 40°C Under vacuum drying to constant weight to obtain acylated polystyrene res...

Embodiment 1

[0031]Example 1: Acylation of polystyrene resin: Weigh the pretreated polystyrene resin white balls into a three-necked flask, add 150 ml of carbon disulfide to swell for 12 hours, and obtain 1.5 g of polystyrene resin. 1.488 g of 2-bromo-2-methylpropionyl bromide was added dropwise with a constant pressure titration funnel, while 2.2 g of catalyst aluminum tribromide was slowly added in batches. Under the condition of 40°C, condense and reflux for 100 minutes, stop the reaction with ultrapure water, cool to room temperature, wash and filter with methanol and ultrapure water 4 times, and finally vacuum dry at 40°C to constant weight to obtain acylated polystyrene resin microspheres.

[0032] Cationic modification of polystyrene resin microspheres: Take 0.25 grams of acylated polystyrene resin microspheres and put them into a single-necked flask, add 7.5896 grams of dimethylformamide solution to swell for 240 minutes, and then add catalyst brominated ketone 0.0156 grams, 0.064...

Embodiment 2

[0033] Example 2: Acylation of polystyrene resin: Weigh the pretreated polystyrene resin white balls into a three-necked flask, add 29 grams of carbon disulfide to swell for 12 hours, and obtain 1.0 g of polystyrene resin. 1.86 g of 2-bromo-2-methylpropionyl bromide was added dropwise with a constant pressure titration funnel, and at the same time, 2.0 g of catalyst aluminum tribromide was slowly added in batches. Under the condition of 50°C, reflux reaction for 120 minutes, stop the reaction with ultrapure water, after cooling to room temperature, wash and filter with methanol and ultrapure water 4 times, and finally vacuum dry at 40°C to constant weight to obtain acylated polystyrene resin microspheres.

[0034] Cationic modification of polystyrene resin microspheres: Take 0.25 grams of acylated polystyrene resin microspheres and put them into a single-necked flask, add 7.5896 grams of dimethylformamide solution to swell for 240 minutes, and then add catalyst brominated keto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com