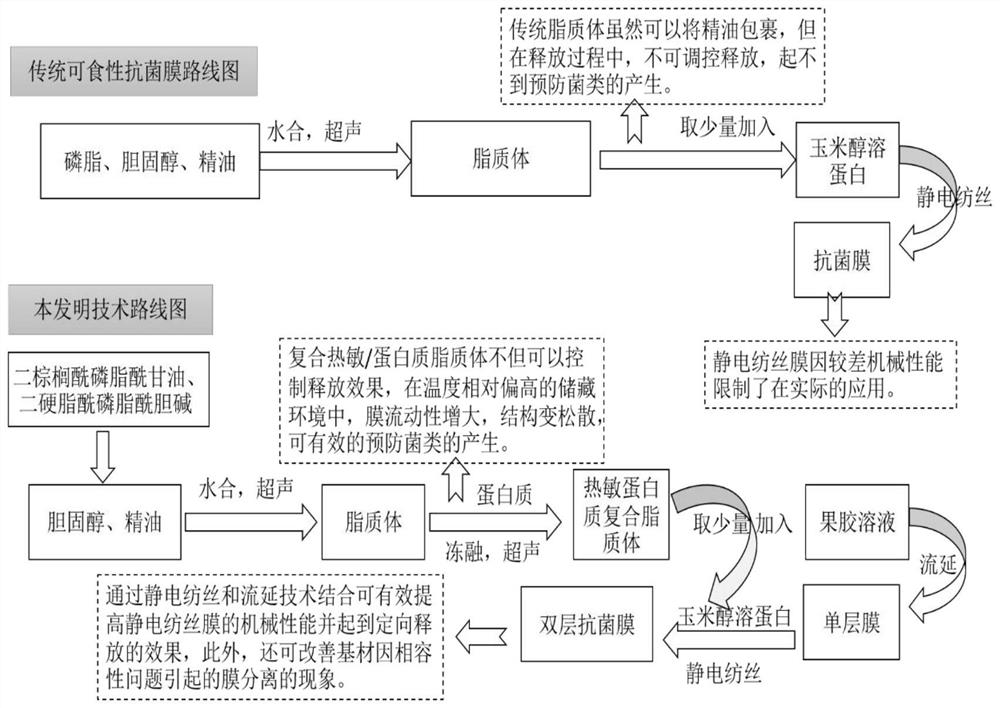

A preparation method of cinnamaldehyde essential oil liposome antibacterial bilayer membrane with adjustable release

A technology of oil liposome and cinnamaldehyde essence, which is applied in the field of food antibacterial packaging, can solve the problems of inability to achieve antibacterial packaging and the like, and achieve the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

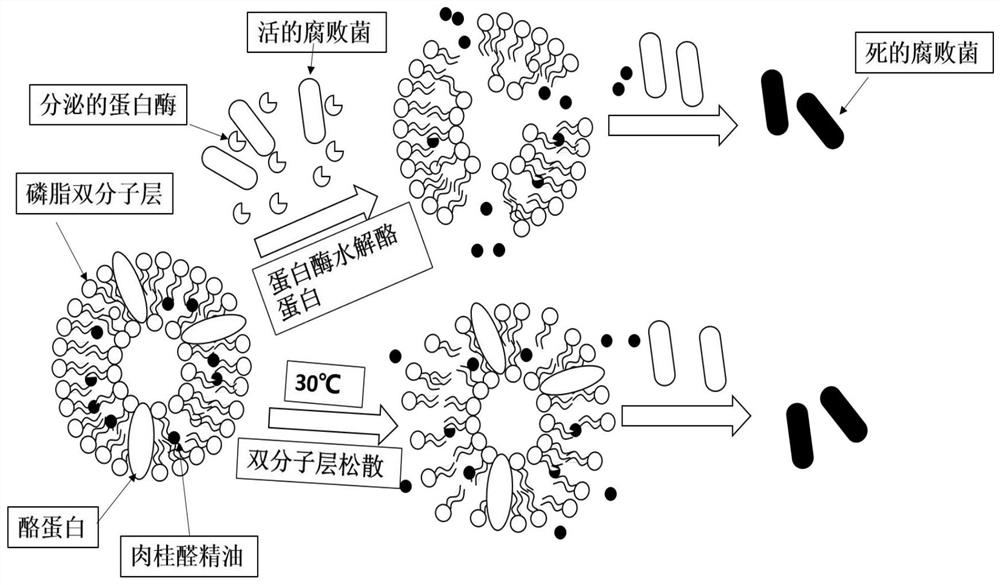

Problems solved by technology

Method used

Image

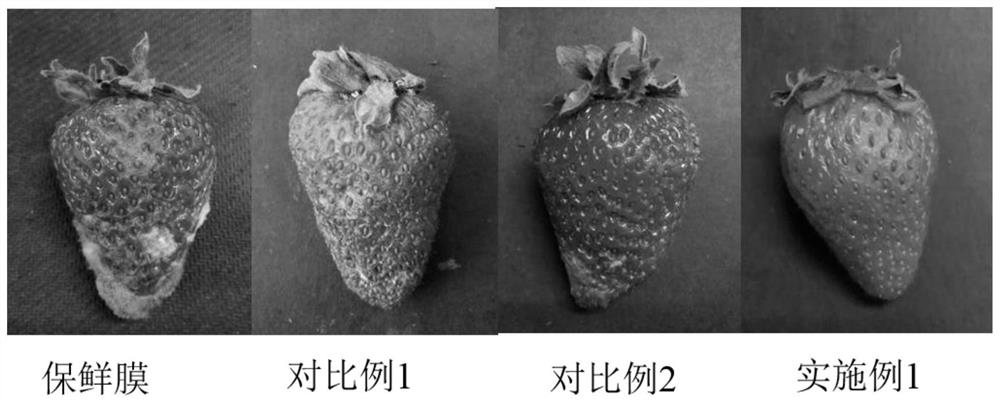

Examples

Embodiment 1

[0049] 1. Preparation of thermosensitive liposomes

[0050] (1) Dissolve 0.4g of dipalmitoylphosphatidylglycerol, 0.2g of distearoylphosphatidylcholine, and 0.2g of cholesterol in 10mL of chloroform, add 200μl of cinnamaldehyde essential oil, and use ultrasound to assist in dissolving, then pour into a circle in the bottom flask.

[0051] (2) Place the round-bottom flask in a rotary evaporator, set the temperature of the rotary evaporator to 40° C., and evaporate the solvent to dryness at 0.08 MPa for 40 minutes under reduced pressure. There is a honeycomb film on the inner wall of the round-bottom flask.

[0052] Add dissolved 0.1 Mm PBS buffer solution into the round bottom flask, hydrate and spin-evaporate for 40 minutes under the condition of 0.02 MPa to obtain a hydrated solution.

[0053] (3) Ultrasonicate the obtained hydration solution at 400 W for 10 min in a closed probe ultrasonic instrument, centrifuge, and filter through a 0.22 μm membrane to obtain heat-sensitiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com