Pitch-based porous carbon material and preparation method thereof, silicon-carbon negative electrode material and secondary battery

A porous carbon material and pitch-based technology, applied in the direction of secondary batteries, battery electrodes, circuits, etc., can solve the problems of low production efficiency, complicated process steps, high production cost, etc., achieve high production efficiency, simple process steps, and reduce production The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] In one aspect, the present invention provides a method for preparing pitch-based porous carbon material, including the following steps:

[0028] The mixture of pitch and pore former obtained after ball milling is calcined to obtain the pitch-based porous carbon material.

[0029] The method for preparing the pitch-based porous carbon material provided by the present invention uses pitch as the raw material to effectively and fully mix the pitch and the pore former through ball milling to obtain a mixture of the two, and then calcine to obtain the porous carbon material. In the preparation method, the carbonization and pore formation of the pitch are completed through a one-time calcination process, the process steps are simple, and complex instruments and equipment are not required, the preparation time is greatly shortened, the production efficiency is high, the production energy consumption is reduced, and the production age is reduced. this.

[0030] In addition, during th...

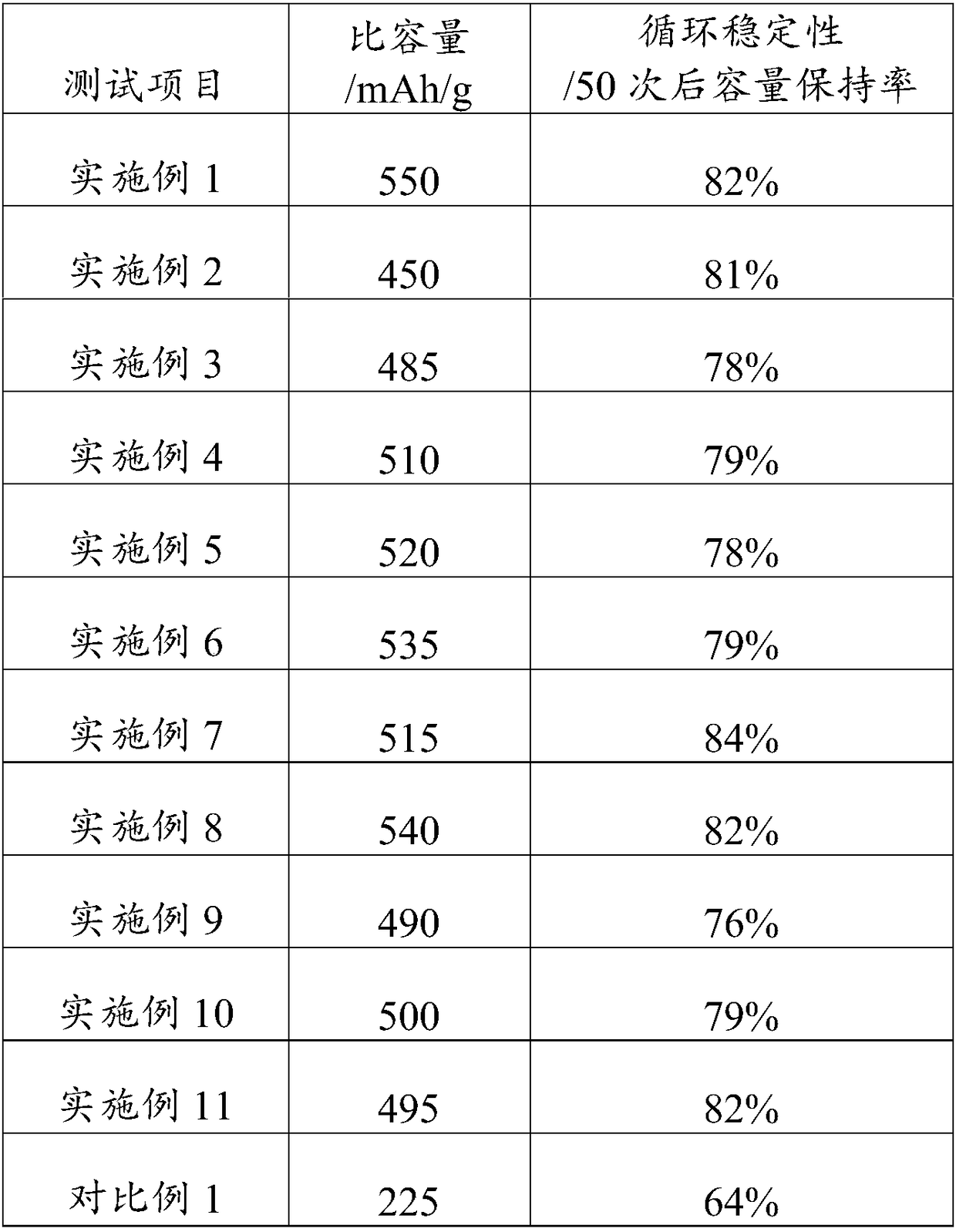

Embodiment 1

[0063] This embodiment is a preparation method of pitch-based porous carbon material, including the following steps:

[0064] a) First, fully dry the asphalt at 30°C, and mix the dried asphalt with potassium hydroxide in a mass ratio of 1:3;

[0065] b) Select agate balls of different diameters, among which the diameters of the agate balls are 5mm, 1cm and 1.5cm respectively;

[0066] c) Put the mixed mixture of pitch and potassium hydroxide and the selected agate balls into a ball mill for 2 hours, and collect the ball milled product. After the material is fully dried, put it into a tube furnace and place it in argon. Calcination in an atmosphere; during calcination, set the furnace temperature to 900°C at a heating rate of 5°C / min and keep it for 1 hour to complete the calcination process;

[0067] d) After the furnace is naturally cooled to room temperature, take out the sample to fully grind, and then wash the sample with dilute nitric acid solution, ethanol solution and deionized...

Embodiment 2

[0069] This embodiment is a method for preparing a pitch-based porous carbon material. The difference from Embodiment 1 is that the mass ratio of pitch to potassium hydroxide in this embodiment is 1:1, and the others are the same as Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com