Preparation method and application of an inorganic-organic composite sludge conditioner

A sludge conditioning and composite technology, which is applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problems of high cost, increased volume of sludge filter cake, and It can reduce the water content and achieve the effect of excellent effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of preparation method of chitosan (CTS)-polyferric chloride (PFC) conditioning agent

[0048] Weigh a certain amount of chitosan at room temperature, dissolve it in 1% to 2% acetic acid solution, and prepare a chitosan solution of 1 to 2 mg / mL; prepare FeCl with a concentration of 0.5 mol / L 3 Put the solution in a beaker, add NaOH solution with a concentration of 0.25mol / L under rapid stirring to obtain a polyferric chloride solution with a degree of alkalinity of 1; Add it into the prepared polyferric chloride solution, wherein the mass ratio of CTS to PFC is 1, and the reaction time is 1h. After the reaction, the beaker was removed to cool down, and aged for 24 hours for later use.

Embodiment 2

[0050] A kind of preparation method of chitosan (CTS)-polyferric chloride (PFC) conditioning agent

[0051] Weigh a certain amount of chitosan at room temperature, dissolve it in 1% to 2% acetic acid solution, and prepare a chitosan solution of 1 to 2 mg / mL; prepare FeCl with a concentration of 0.5 mol / L 3 Put the solution in a beaker, add NaOH solution with a concentration of 0.25mol / L under rapid stirring to obtain a polyferric chloride solution with a degree of alkalinity of 1; Add it into the prepared polyferric chloride solution, wherein the mass ratio of CTS to PFC is 1.5, and the reaction time is 2h. After the reaction, the beaker was removed to cool down, and aged for 24 hours for later use.

Embodiment 3

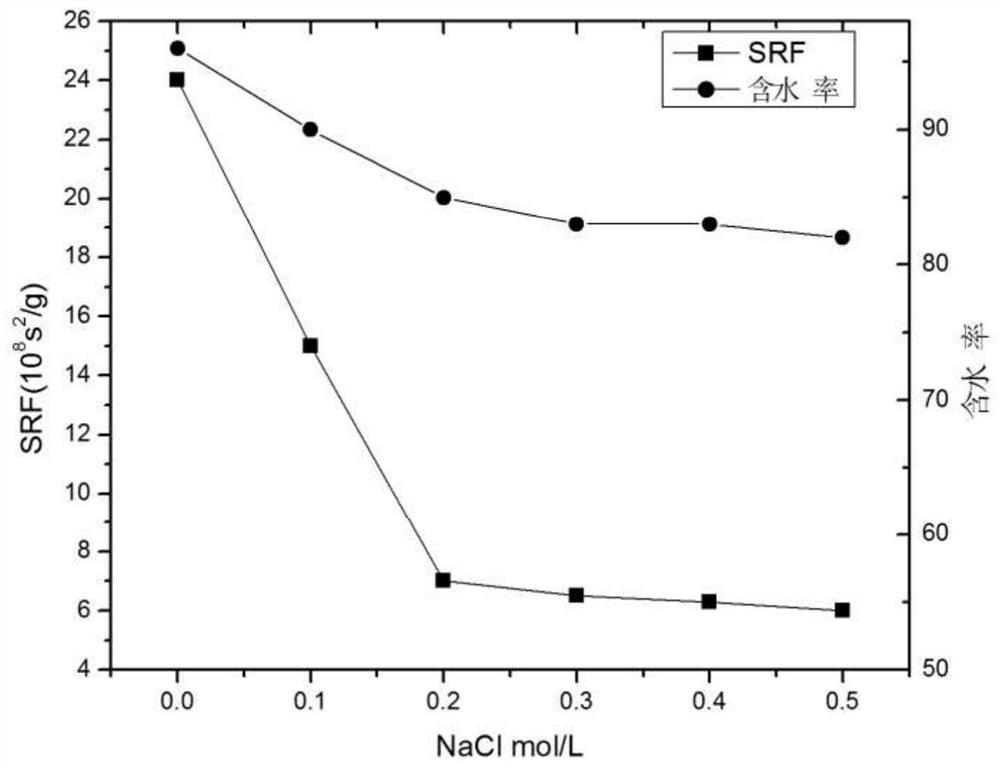

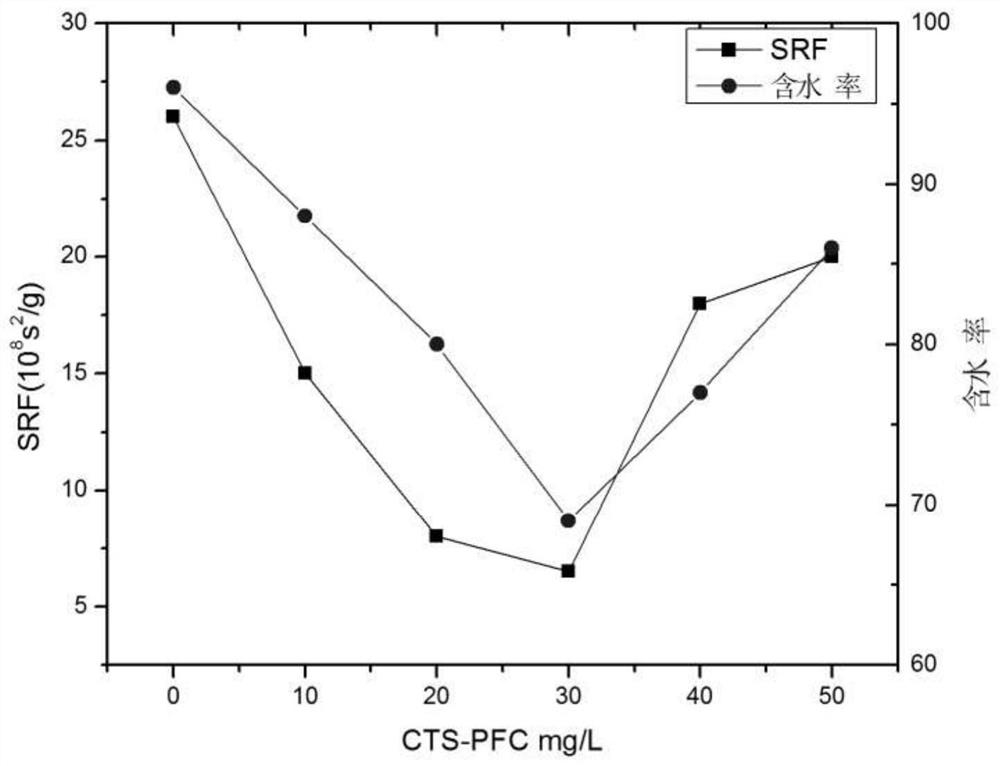

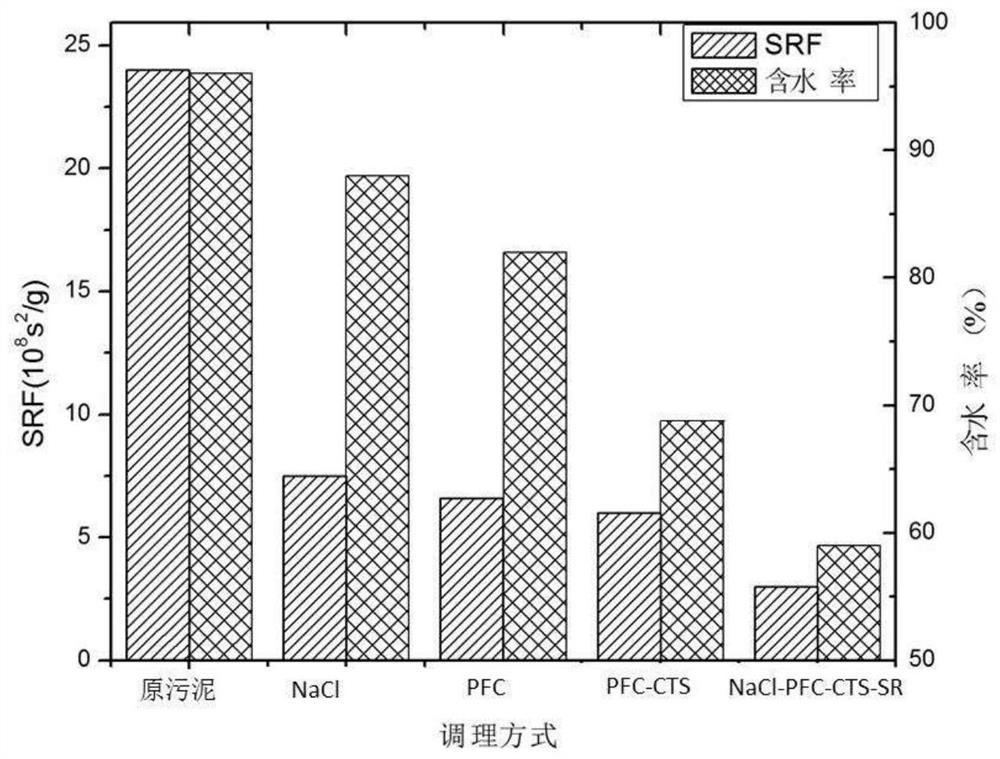

[0053] A kind of method for sludge conditioning of inorganic-organic composite sludge conditioner

[0054] At first, add 500mL sludge sample in the beaker that measuring range is 1L, join the NaCl solution of 0,0.1,0.2,0.3,0.4,0.5mol / L in the beaker, stir 120 minutes at 80r / min; Then add (Example 1 sludge conditioner) 30mg / L The prepared sludge conditioner sludge mixture was stirred at 300r / min for 30s, then stirred at 80r / min for 3min; finally the sludge pyrolysis residue of 50% of the total mass of the aforementioned sludge was The powder (SR) was added into the beaker, and the sludge mixture was stirred at 80r / min for 5min.

[0055] The preparation method of sludge pyrolysis residue powder is to take a certain amount of sludge and put it into a microwave oven with a power of 1200W and a pyrolysis time of 20 minutes. After the pyrolysis is completed, take it out and grind it to pass through a 200-mesh sieve; the water content of the sludge residue is 0.

[0056] Among them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com